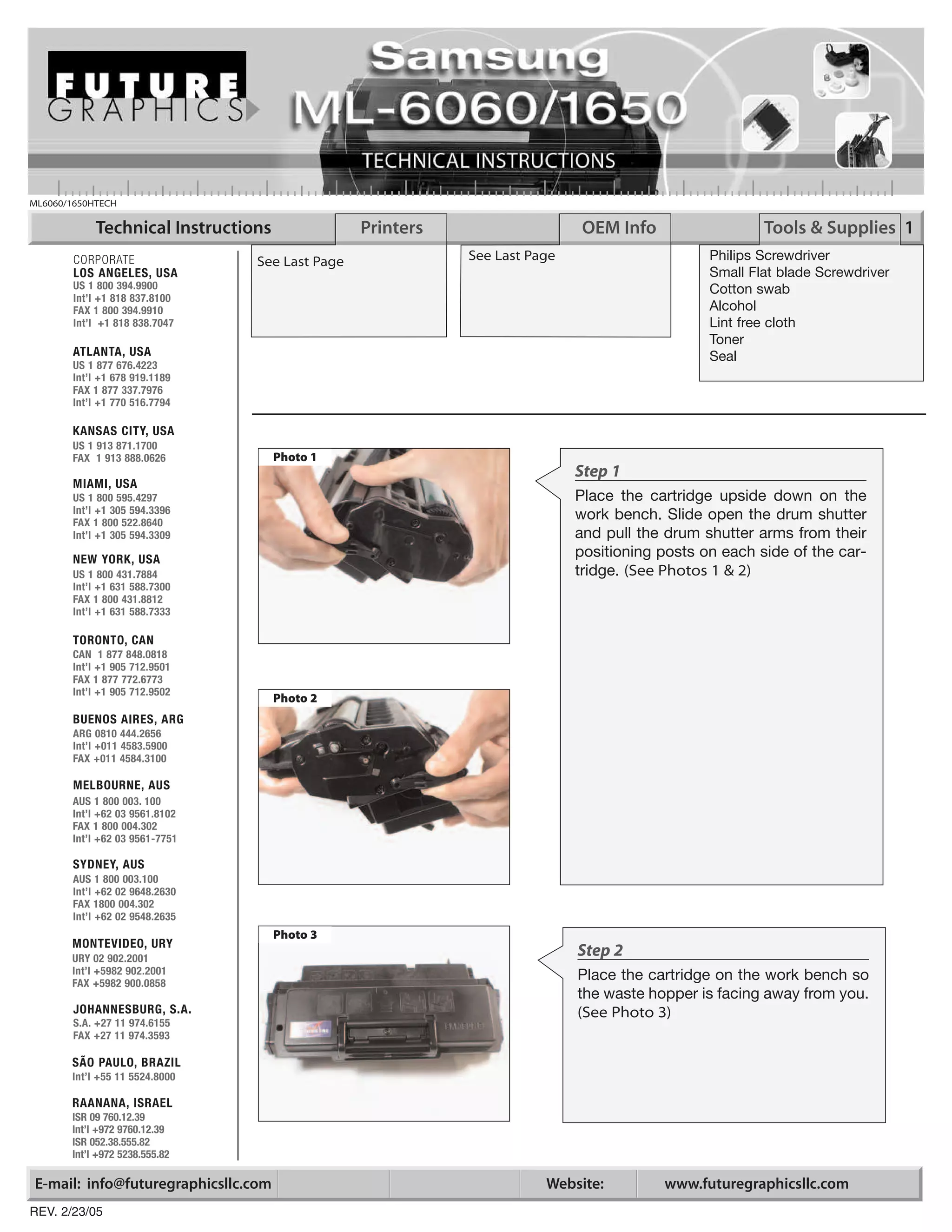

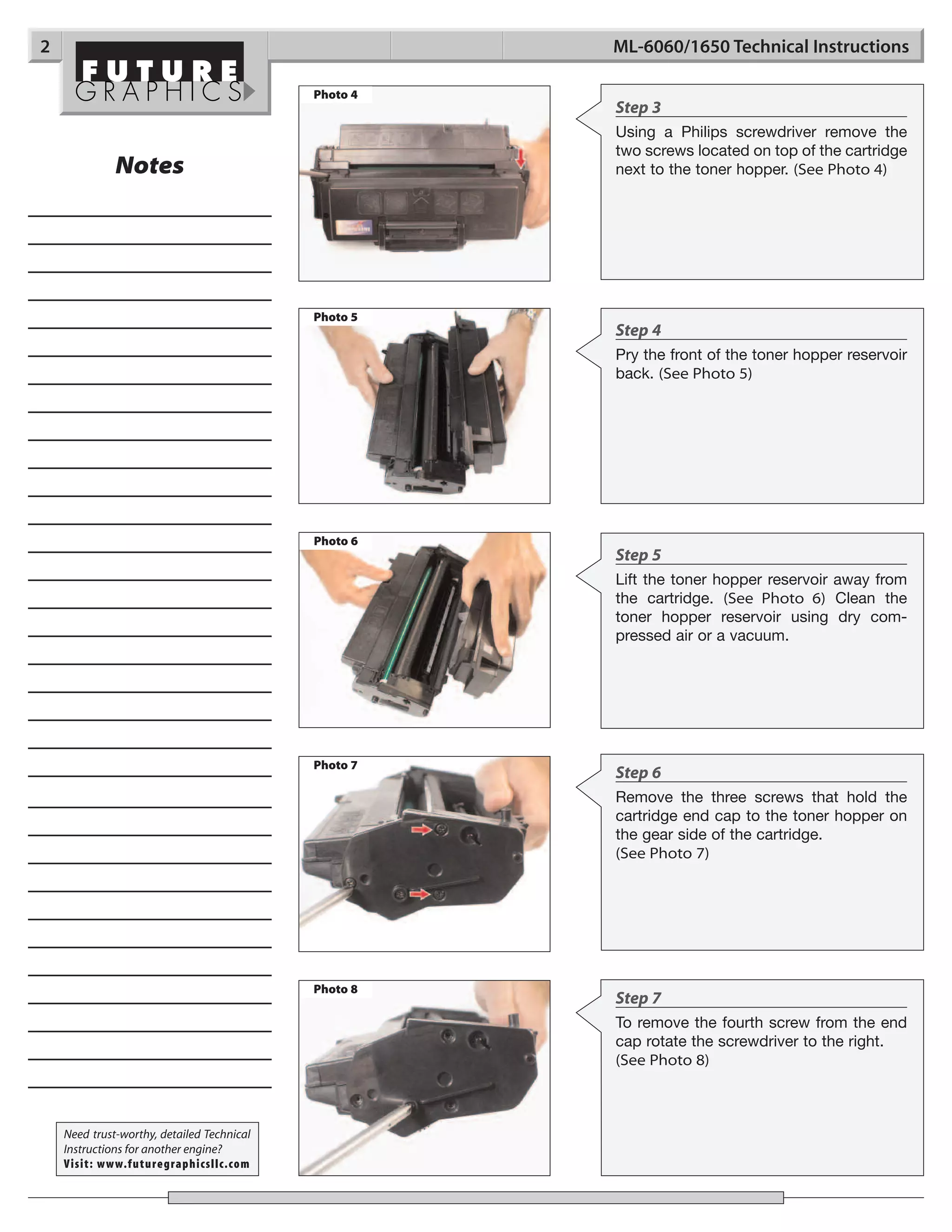

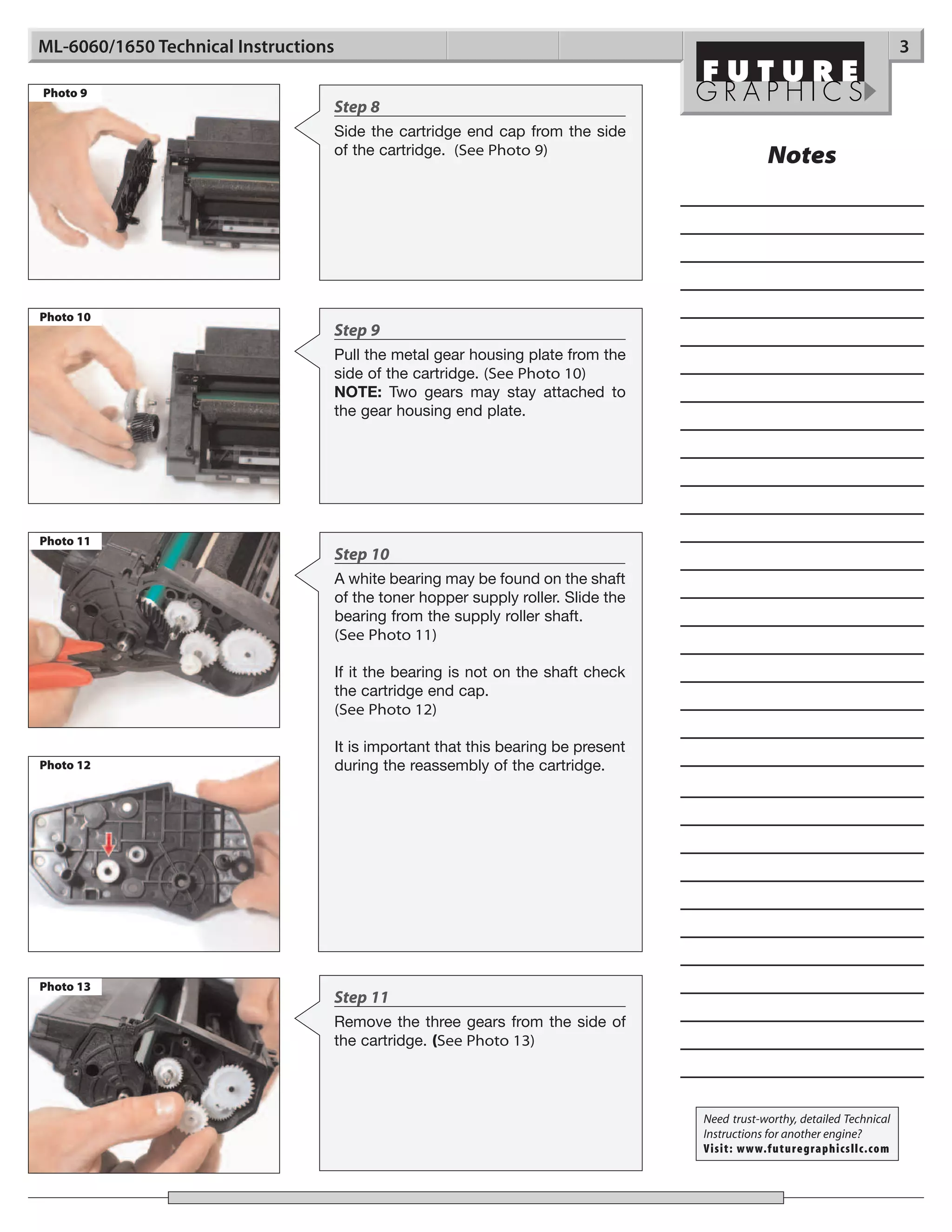

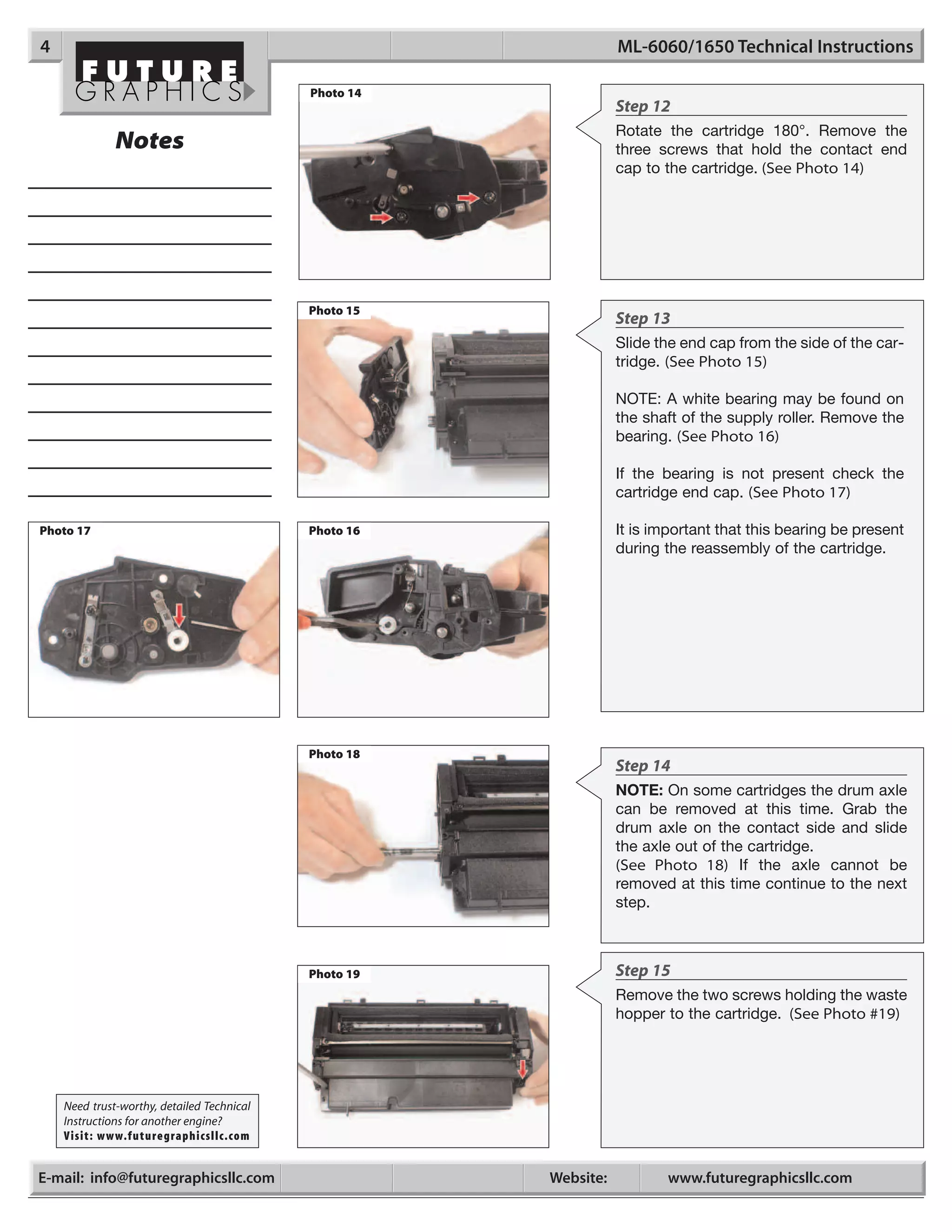

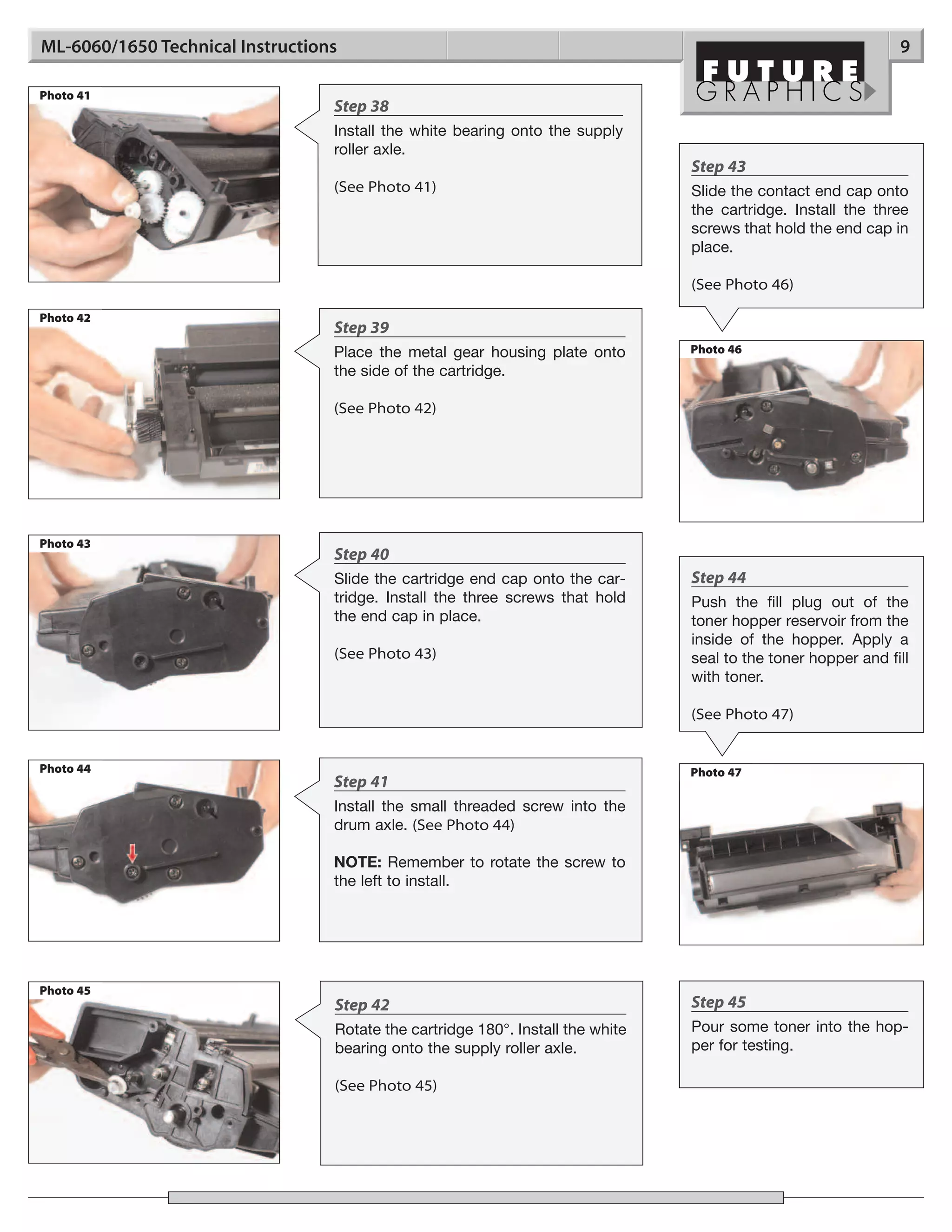

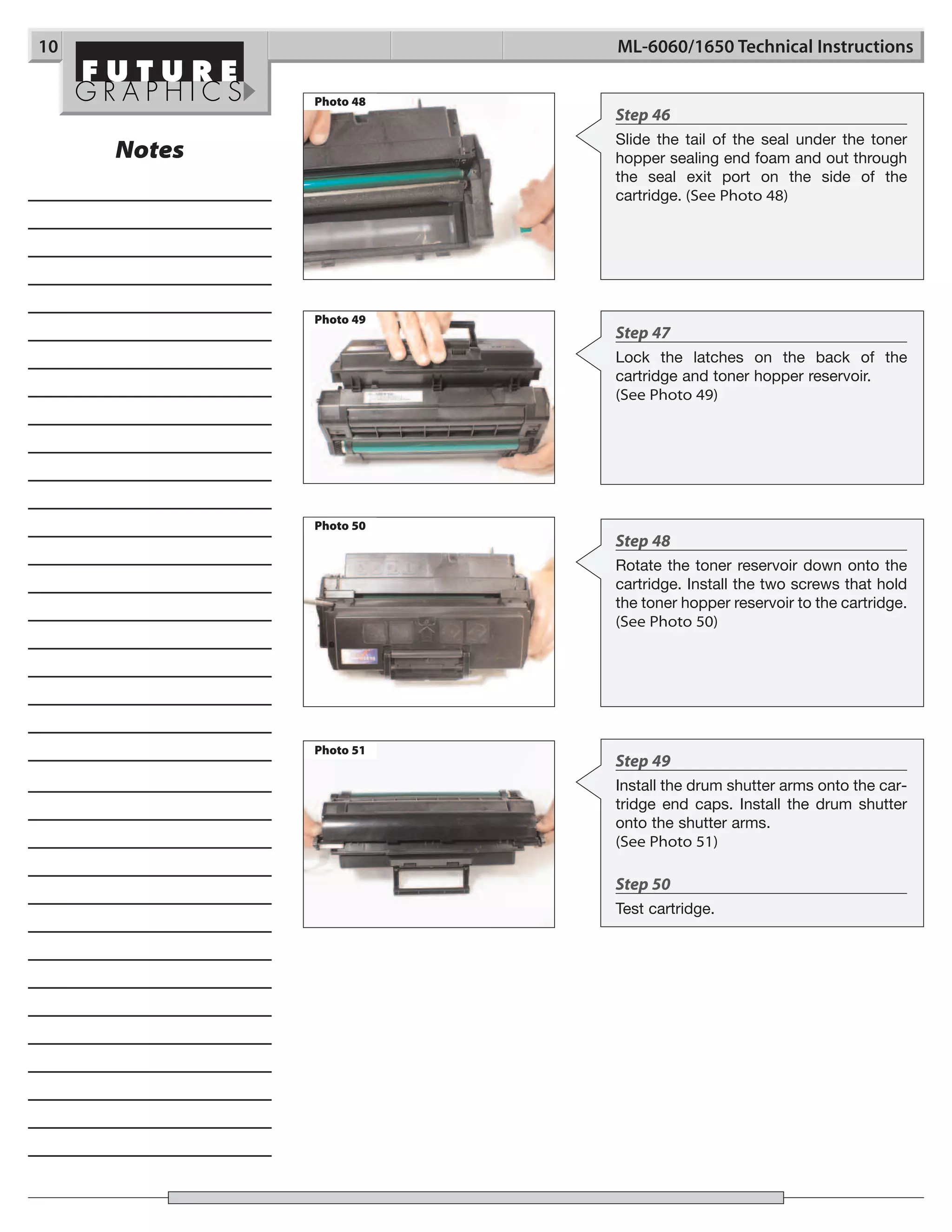

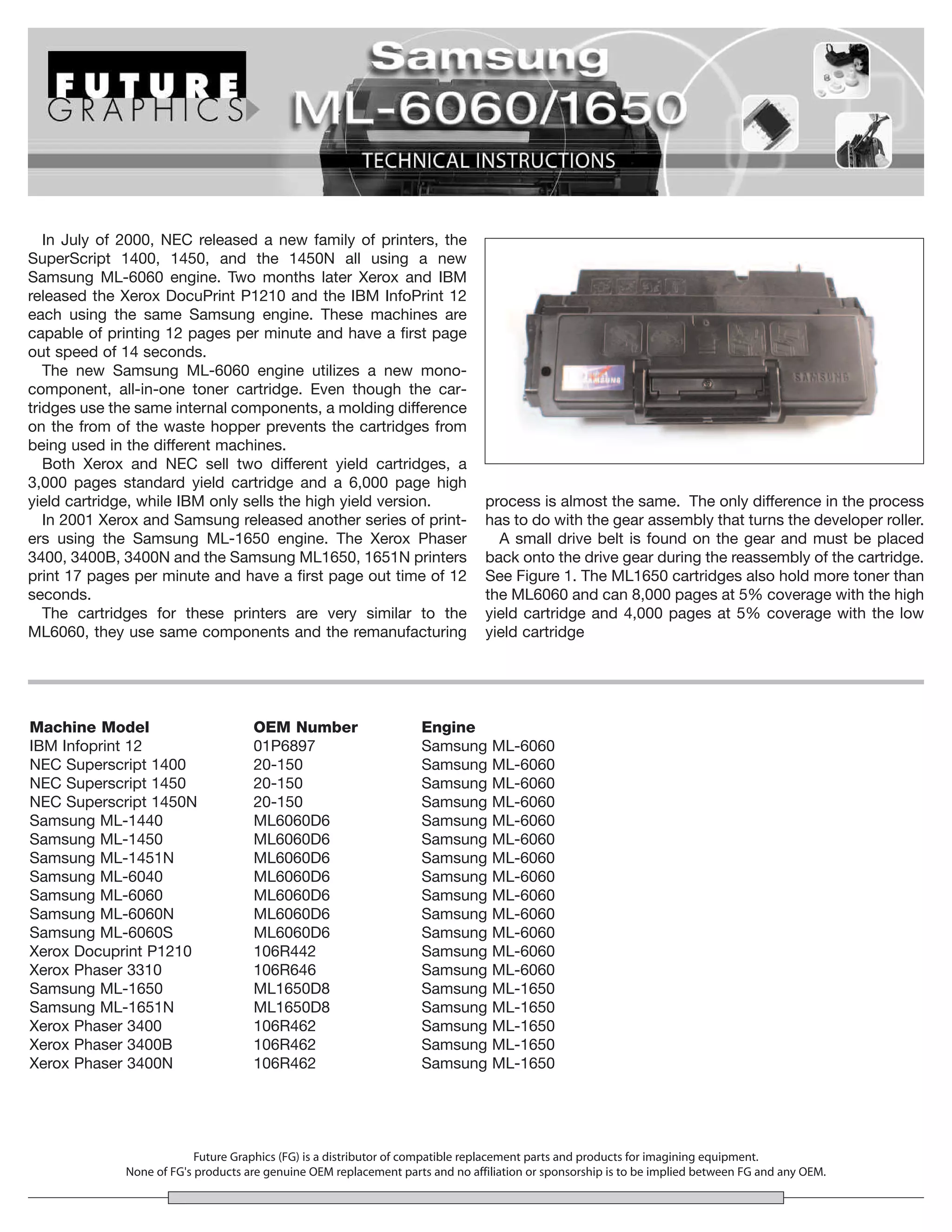

The document provides detailed technical instructions for servicing Samsung ML-6060 and ML-1650 printer cartridges, including step-by-step processes for disassembly, cleaning, and reassembly. It outlines necessary tools, safety notes, and troubleshooting tips, along with specific steps for removing and replacing various cartridge components. Additionally, it includes a comparison of cartridge yield options and details the printer models that utilize these cartridges.