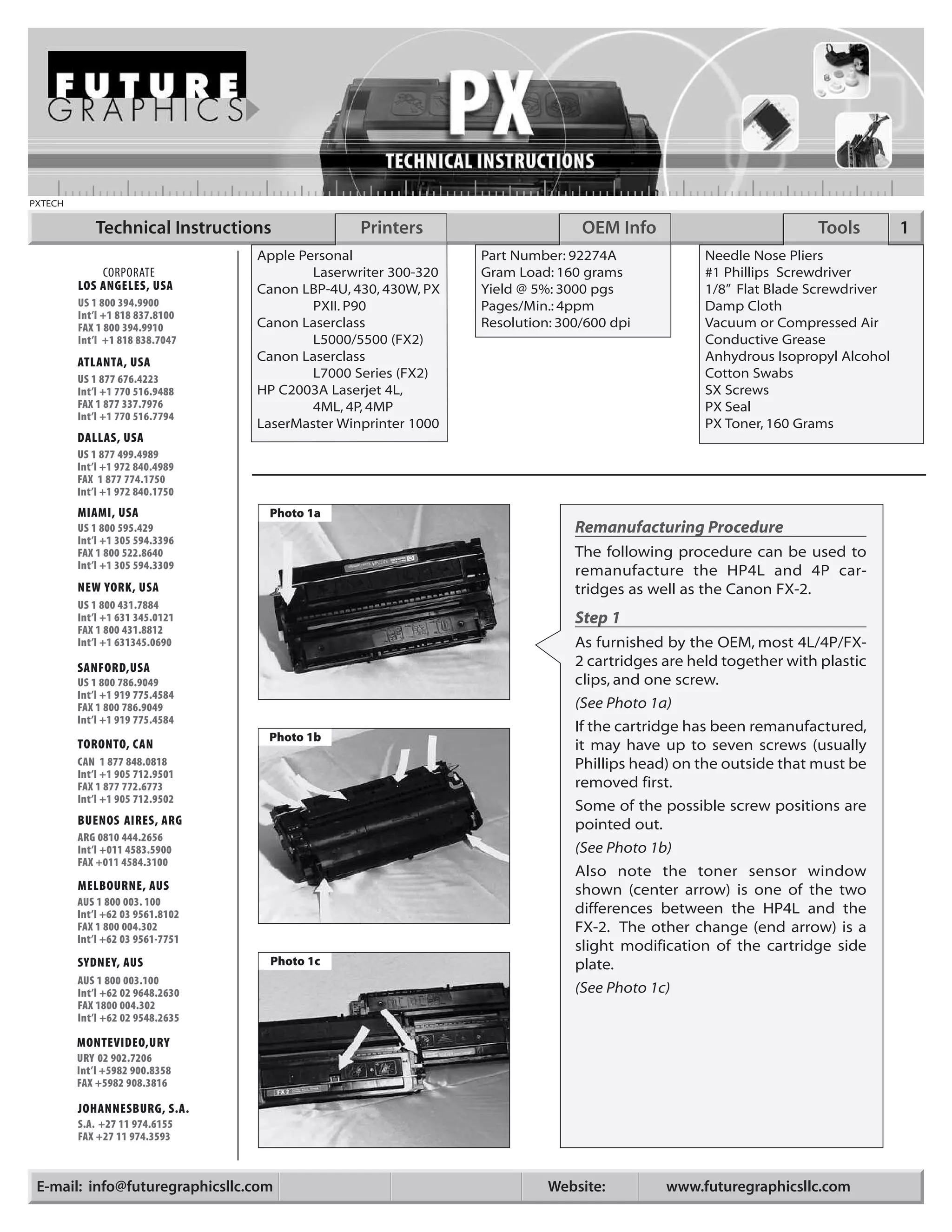

The document provides technical instructions for remanufacturing toner cartridges for various printer models, including the HP 4L, 4P, and Canon FX-2. It outlines a 9 step process that involves removing screws and plastic clips to separate the cartridge into its main components in order to clean it and replace the toner. Key steps include releasing the drum cover, separating the toner and waste hoppers, removing the toner mixer gear, and cleaning sensor windows before resealing the cartridge.