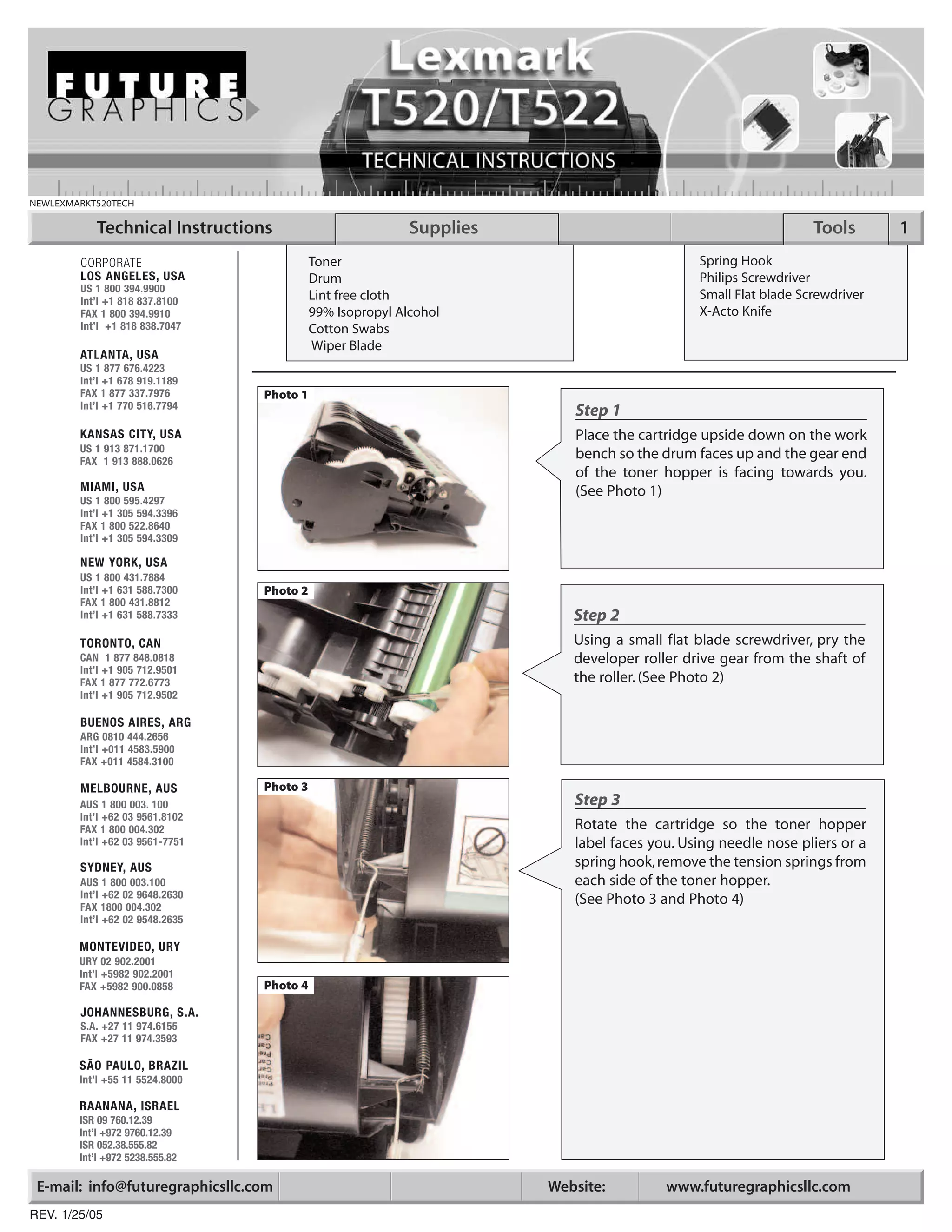

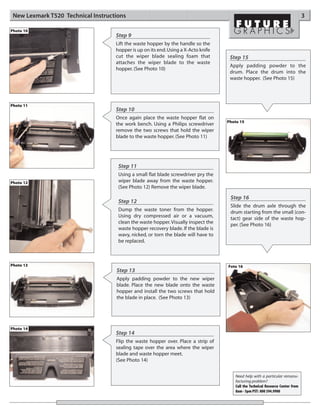

This document provides technical instructions for remanufacturing the toner cartridge for the Lexmark T520 printer. It has undergone changes to simplify the remanufacturing process. The instructions are presented in 42 steps with accompanying photos. The main change is that the doctor blade now has a centered contact with the developer roller instead of an offset contact, preventing the old trick of flipping the doctor blade.