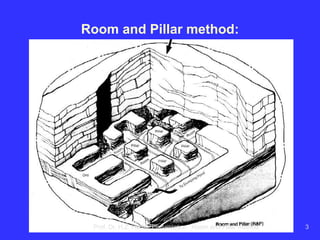

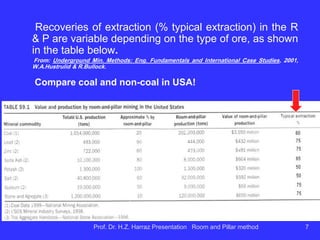

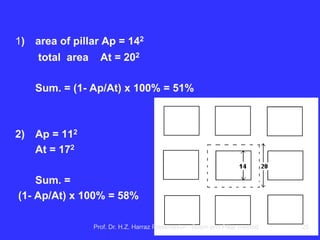

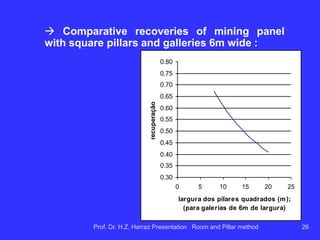

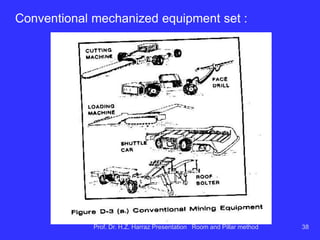

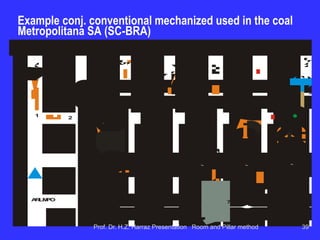

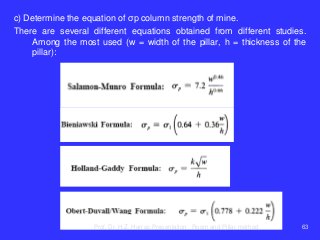

The document discusses the room and pillar (R&P) mining method, which is widely used for mining both coal and non-coal resources. It outlines the practical importance, applications, design parameters, and advantages and disadvantages of this method, including its effectiveness in various geological conditions and the mechanical requirements for extraction. It also provides insights into recovery rates, equipment used, and different configurations applicable to both hard and soft rock environments.

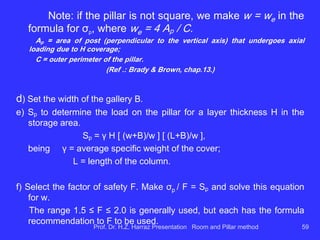

![Note: if the pillar is not square, we make w = we in the

formula for σp, where we = 4 Ap / C.

Ap = area of post (perpendicular to the vertical axis) that undergoes axial

loading due to H coverage;

C = outer perimeter of the pillar.

(Ref .: Brady & Brown, chap.13.)

d) Set the width of the gallery B.

e) Sp to determine the load on the pillar for a layer thickness H in the

storage area.

Sp = γ H [ (w+B)/w ] [ (L+B)/w ],

being γ = average specific weight of the cover;

L = length of the column.

f) Select the factor of safety F. Make σp / F = Sp and solve this equation

for w.

The range 1.5 ≤ F ≤ 2.0 is generally used, but each has the formula

recommendation to F to be used.

Prof. Dr. H.Z. Harraz Presentation Room and Pillar method 64](https://image.slidesharecdn.com/3-roomandpillar-141022163816-conversion-gate01/85/Room-and-Pillar-Mining-Method-64-320.jpg)

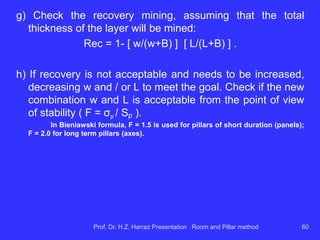

![g) Check the recovery mining, assuming that the total

thickness of the layer will be mined:

Rec = 1- [ w/(w+B) ] [ L/(L+B) ] .

h) If recovery is not acceptable and needs to be increased,

decreasing w and / or L to meet the goal. Check if the new

combination w and L is acceptable from the point of view

of stability ( F = σp / Sp ).

In Bieniawski formula, F = 1.5 is used for pillars of short duration (panels);

F = 2.0 for long term pillars (axes).

Prof. Dr. H.Z. Harraz Presentation Room and Pillar method 65](https://image.slidesharecdn.com/3-roomandpillar-141022163816-conversion-gate01/85/Room-and-Pillar-Mining-Method-65-320.jpg)