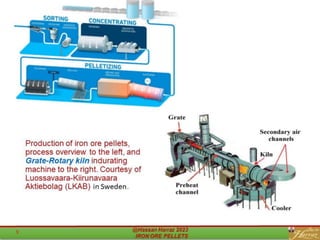

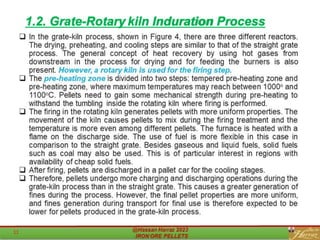

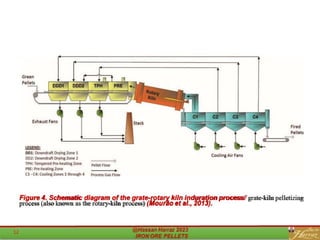

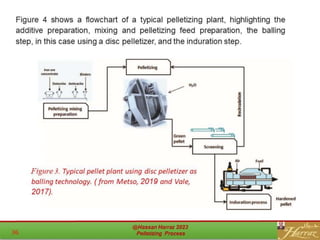

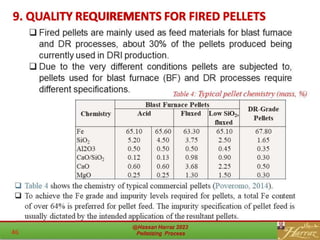

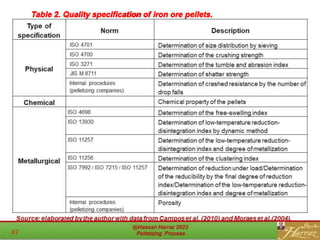

The document provides an overview of the iron ore pelletizing process, detailing the various types of induration technologies such as the straight grate and grate-rotary kiln processes. It discusses preparation methods, specification requirements for pellet feed, and the formation and properties of green balls, along with the use of binders. Additionally, it addresses market forecasts and challenges in pelletizing, highlighting innovations and trends in the industry.

![Figure 1. World installed pelletizing capacity (millions of tonnes/year).

Source: Prepared by the author with data from Tuck and Virta [2011].](https://image.slidesharecdn.com/pelletizingprocess-231129074623-a69e0e0f/85/Pelletizing-Process-pdf-21-320.jpg)

![References

Abouzeid A, Seddik A. Effectof Iron Ore Properties on its Balling Behavior. Elsevier Sequoia S.A.: Lausanne; 1980

Ball D. Agglomeration of Iron Ores. New York: American Elsevier Pub. Co.; 1973

Biswas, A.K. Principles of Blast Furnace Ironmaking; Cootha Publishing House: Brisbane, Australia, 1981; pp. 33–39. ISBN 10:0949917001.

Borim J. Modelagem e controle de um processo de endurecimento de pelotas de minério de ferro [dissertation]. Belo Horizonte: Universidade Federal de

Minas Gerais; 2000

Campos A, FonsecaV. Pelotização. In: Luz A, Sampaio J, França S, editors.Tratamento de minérios. 5th ed. Rio de Janeiro: CETEM/MCT; 2010. pp. 705-750

China Metallurgical Construction Association. Code for Design of Iron Pelletizing Engineering; China Planning Press: Beijing, China, 2009; pp. 20–25. ISBN

1580177244.

Fu, J.Y.; Zhu, D.Q. Basic Principles, Techniques and Equipment of the Iron Ore Oxidized Pellets; Central South University Press: Changsha, China, 2005; pp. 323–

336. ISBN 9787811050516.

Gao, Q.; Shen, F.; Jiang, X.; Wei, G.; Zheng, H.Y. Gas-solid reduction kinetic model of MgO-fluxed pellets. Int. J. Miner. Metall. Mater. 2014, 21, 12–17. [CrossRef]

Haas LA, Aldinger JA, Zahl RK. Effectiveness of Organic Binders for Iron Ore Pelletization. Pittsburgh: U.S. Department of the Interior. Bureau of Mines; 1989

(Report of Investigations, RI 9230)

Lima J. Estudo da carboxi-metil-celulose como aglomerante para pelotização [thesis]. São Paulo: Escola Politécnica da Universidade São Paulo; 1991

Metso. Iron ore pelletizing [Internet].2017. Available from: http://www.metso.com/products/iron-ore-pelletizing/ [Accessed: October06, 2017]

Meyer K. Pelletizing of Iron Ores.Heidelberg: Springer-Verlag; 1980. p. 291 não encontrado

Moraes S, Comparação de desempenho de aglomerante orgânico em relação à bentonita na operação de pelotização de concentrados de minério de ferro

brasileiros de diversasprocedências.[dissertation].São Paulo: Escola Politécnica da Universidade São Paulo; 2004

Moraes S, Lima J, Neto J. Influence of dispersants on the rheological and colloidal properties of iron ore ultrafine particles and their effect on the pelletizing

process—Areview. Journal of Materials Research and Technology.2013;2:386-391

Mourão J, Huerta M, de Medeiros U, Cameron I, O’Leary K, Howey C. Guidelines for selecting pellet plant technology. In: 6th International Congress on the

Science and Technology of Ironmaking-ICSTI, Rio de Janeiro, RJ, Brazil, October 14–18, 2012, pp. 2162–2175.

Mourão J. Estudo Prospectivo do Setor Siderúrgico: NT Minério de Ferro e Pelotas Situação Atual e Tendências 2025. Brasília: Centro de Gestão e Estudos

Estratégicos; 2008

Nabeel, M.; Karasev, A.; Jönsson, P.G. Evaluation of dust generation during mechanical wear of iron ore pellets. ISIJ Int. 2016, 56, 960–966. [CrossRef]

Sadrnezhaad, S.K.; Ferdowsi, A.; Payab, H. Mathematical model for a straight grate iron ore pellet induration process of industrial scale. Comp. Mater. Sci. 2009,

44, 296–302. [CrossRef]

Sandra Lúcia de Moraes, José Renato Baptista de Lima and Tiago Ramos Ribeiro. Iron Ore Pelletizing Process: An Overview. Chapter 3.

http://dx.doi.org/10.5772/intechopen.73164

Shen, F.; Gao, Q.; Jiang, X.; Wei, G.; Zheng, H. Effect of magnesia on the compressive strength of pellets. Int. J. Miner. Metall. Mater. 2014, 21, 431–437.

[CrossRef]

Tuck C, Virta R. 2011 minerals yearbook: Iron ore. USGS [Internet]. 2013. Available from: http://minerals.usgs.gov/minerals/pubs/commodity/iron_ore/myb1-

2011-feore.pdf [Accessed: May, 2014]

Vale. Entenda como funciona o processo de pelotização em nossas usinas [Internet]. 2017. Available from:

http://www.vale.com/brasil/PT/aboutvale/news/Paginas/entenda-funcionaprocesso-pelotizacao-usinas.aspx[Accessed: October 06, 2017]

Wynnckyj J, Fahidy T. Solid state sintering in the induration of iron ore pellets. Metallurgical Transactions. 1974; 5: 991-999](https://image.slidesharecdn.com/pelletizingprocess-231129074623-a69e0e0f/85/Pelletizing-Process-pdf-53-320.jpg)