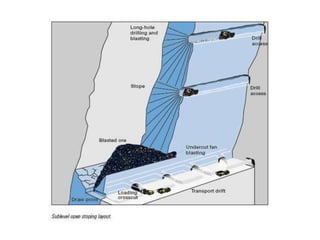

Sublevel open stopping is a vertical mining method where a large open stope is created within an ore vein. Three variations are used: blast hole, open ending, and vertical crater retreat. Drilling is done from multiple sublevels using fan or parallel patterns. Ore is mucked using load haul dump equipment or slushers and transported to surface via skips or haul trucks. Pillars are left in place for support and ground conditioning uses bolts. Backfill allows for recovery of up to 90% of ore while providing support. It is suitable for moderate to strong ore bodies that are fairly steep, thick, and tabular in shape. Advantages include moderate productivity while disadvantages include complex development and inflexible planning.