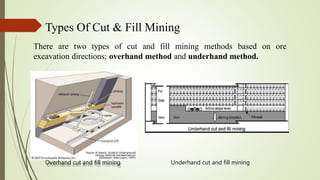

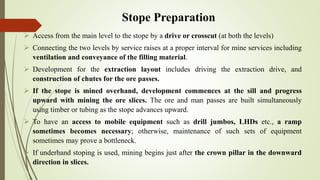

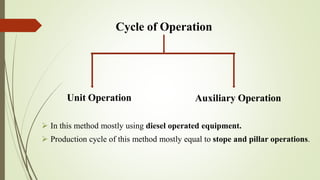

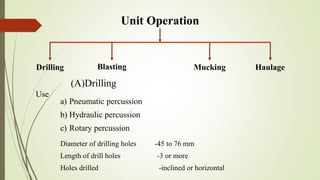

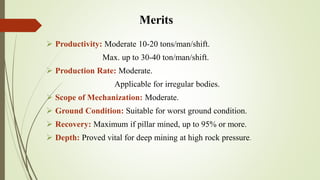

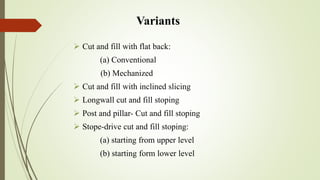

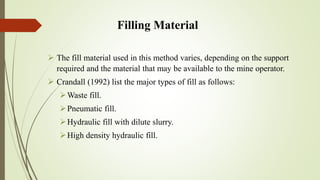

The document discusses the cut and fill underground mining method. It involves cutting slices of ore and replacing the void created with fill material in a cyclic process. There are two types - overhand and underhand. Overhand mines from the bottom up while underhand mines from the top down. The process involves drilling, blasting, mucking out the ore, hauling it away, and filling the void with waste material. It is suitable for deposits that are too irregular for other methods or in poor ground conditions.