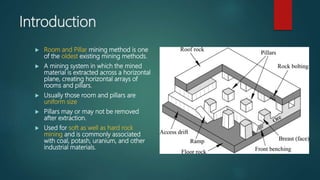

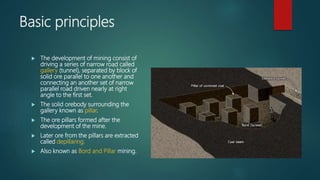

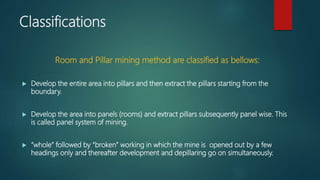

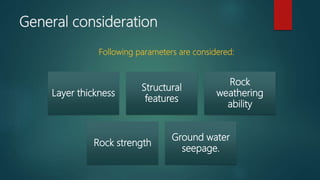

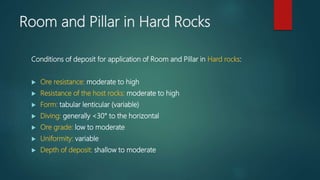

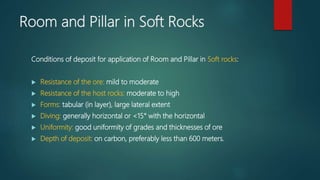

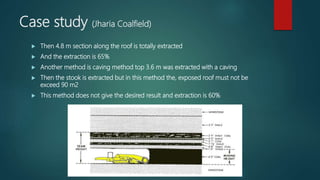

The document provides an in-depth overview of the room and pillar mining method, one of the oldest mining techniques used for extracting materials from horizontal planes. It details its usability, geological requirements, basic principles, classifications, design parameters, advantages, disadvantages, and a case study from Jharia coal field. The method is widely used in various countries, particularly for coal extraction, with a focus on balancing resource recovery and safety in mining operations.