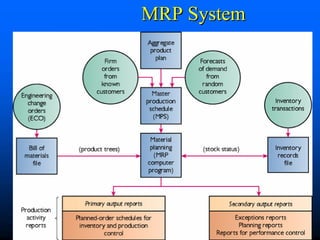

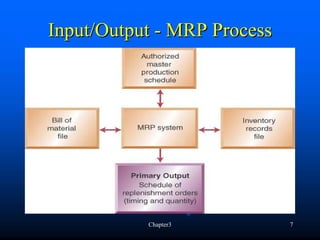

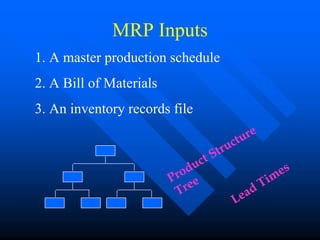

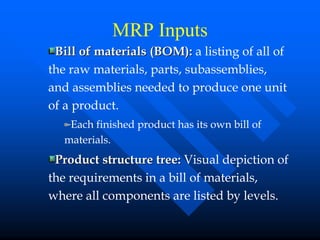

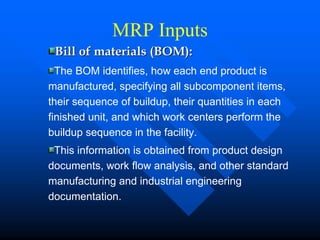

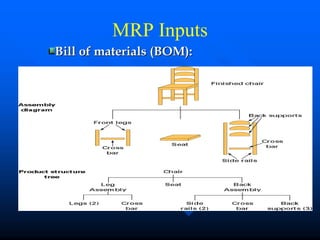

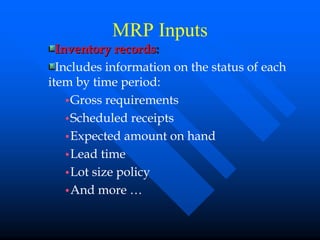

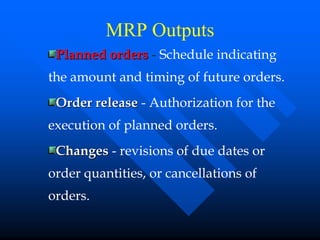

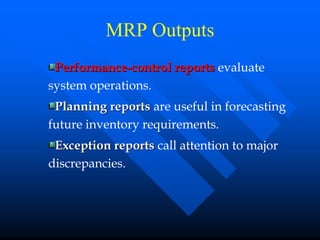

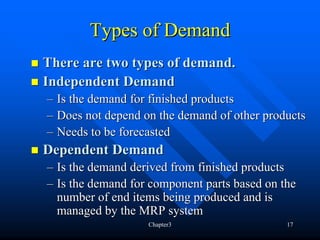

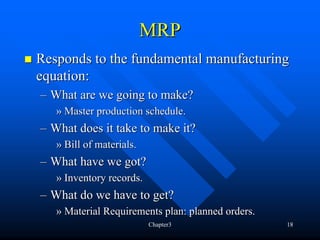

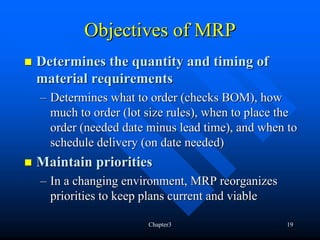

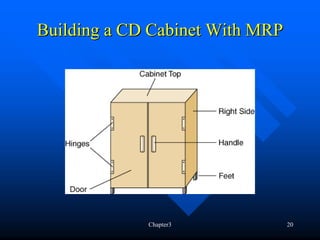

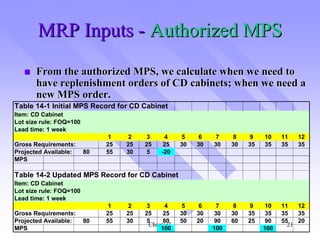

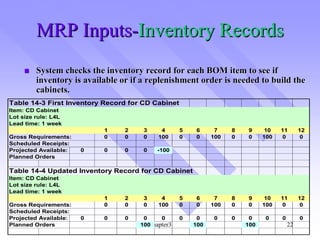

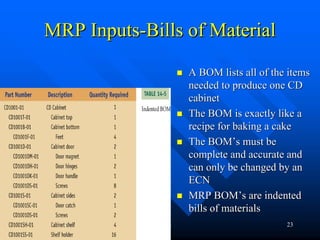

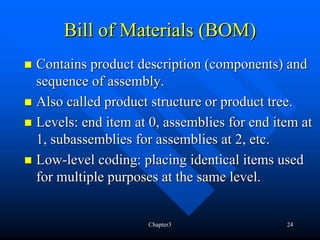

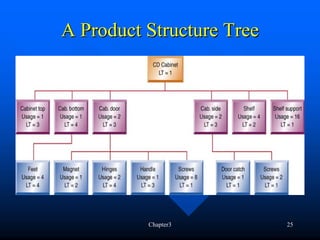

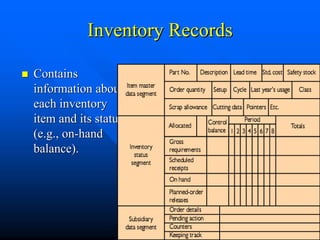

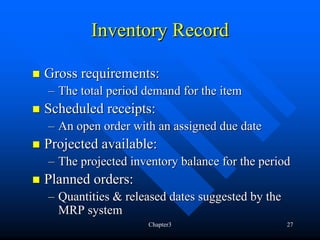

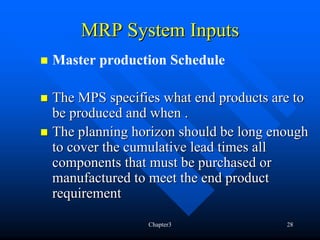

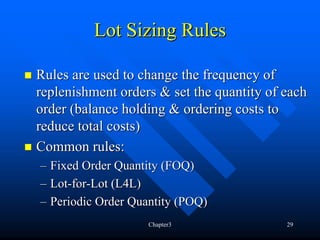

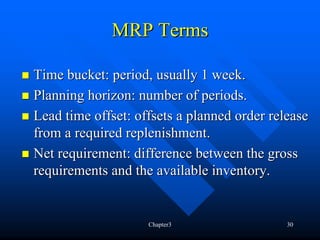

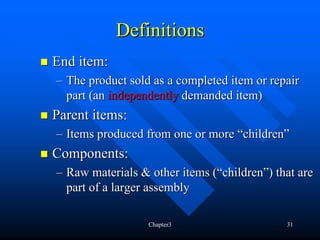

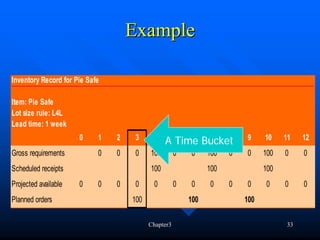

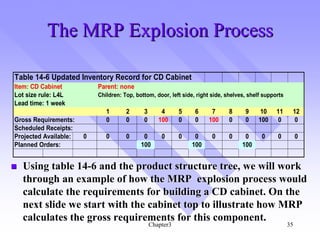

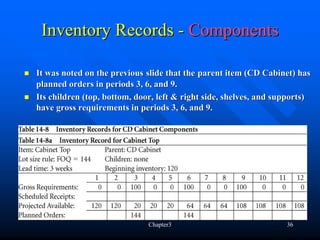

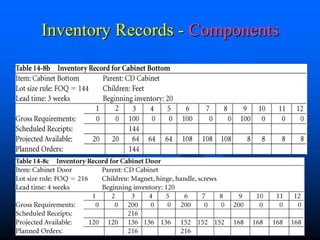

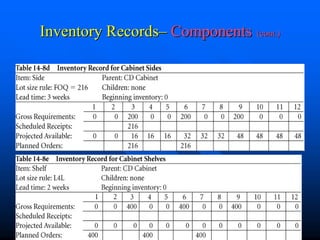

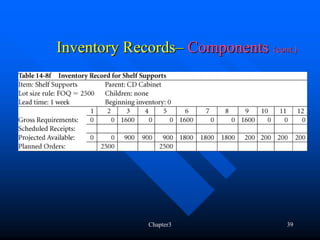

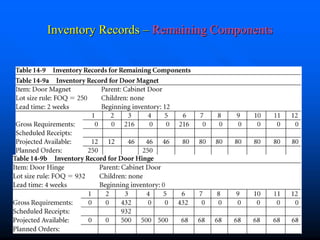

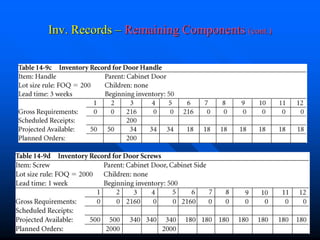

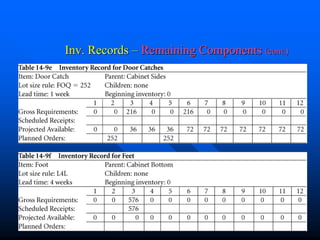

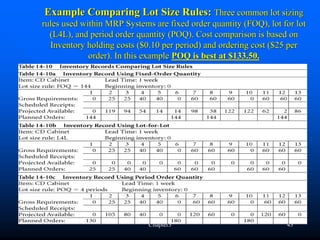

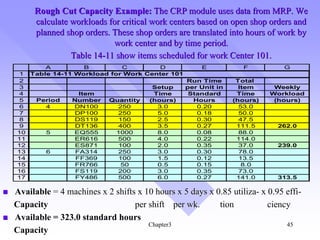

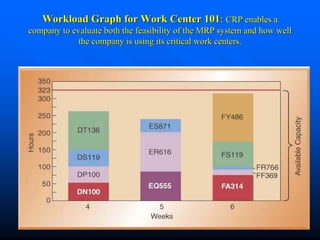

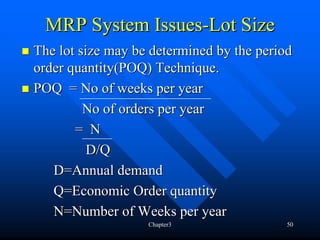

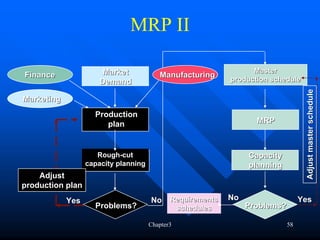

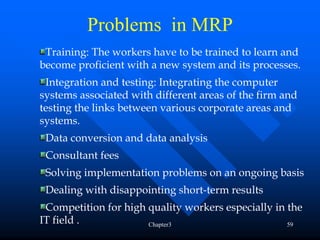

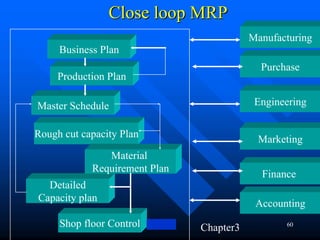

The document provides an in-depth overview of Material Requirements Planning (MRP) systems, outlining their evolution from basic reorder point systems to sophisticated MRP II systems that integrate various internal functions. It describes the inputs required for MRP, including the master production schedule, bills of materials, and inventory records, as well as the outputs such as planned orders and performance-control reports. Additionally, it addresses issues related to MRP, including safety stock, lot sizing, and the importance of accurate inventory records.