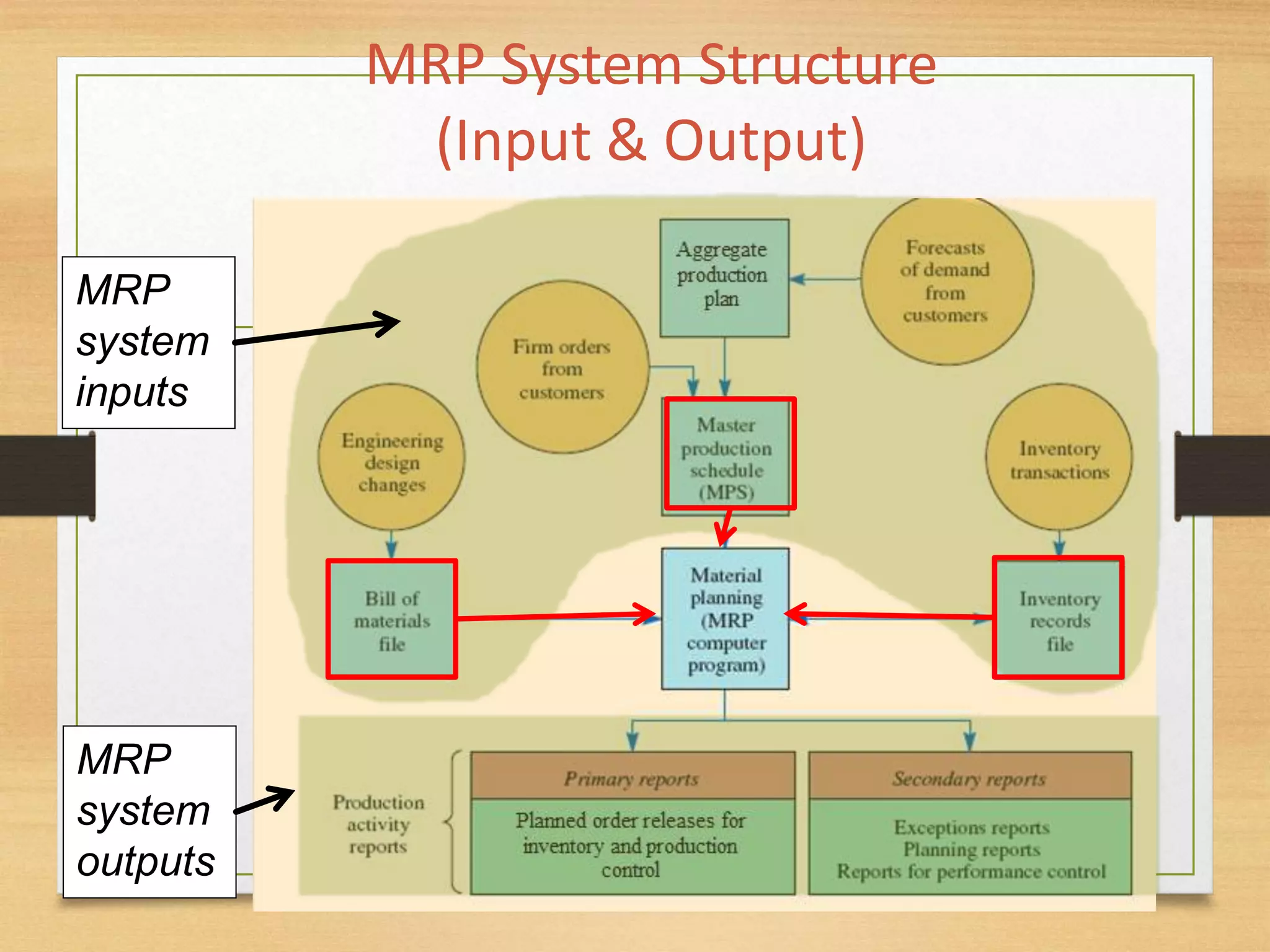

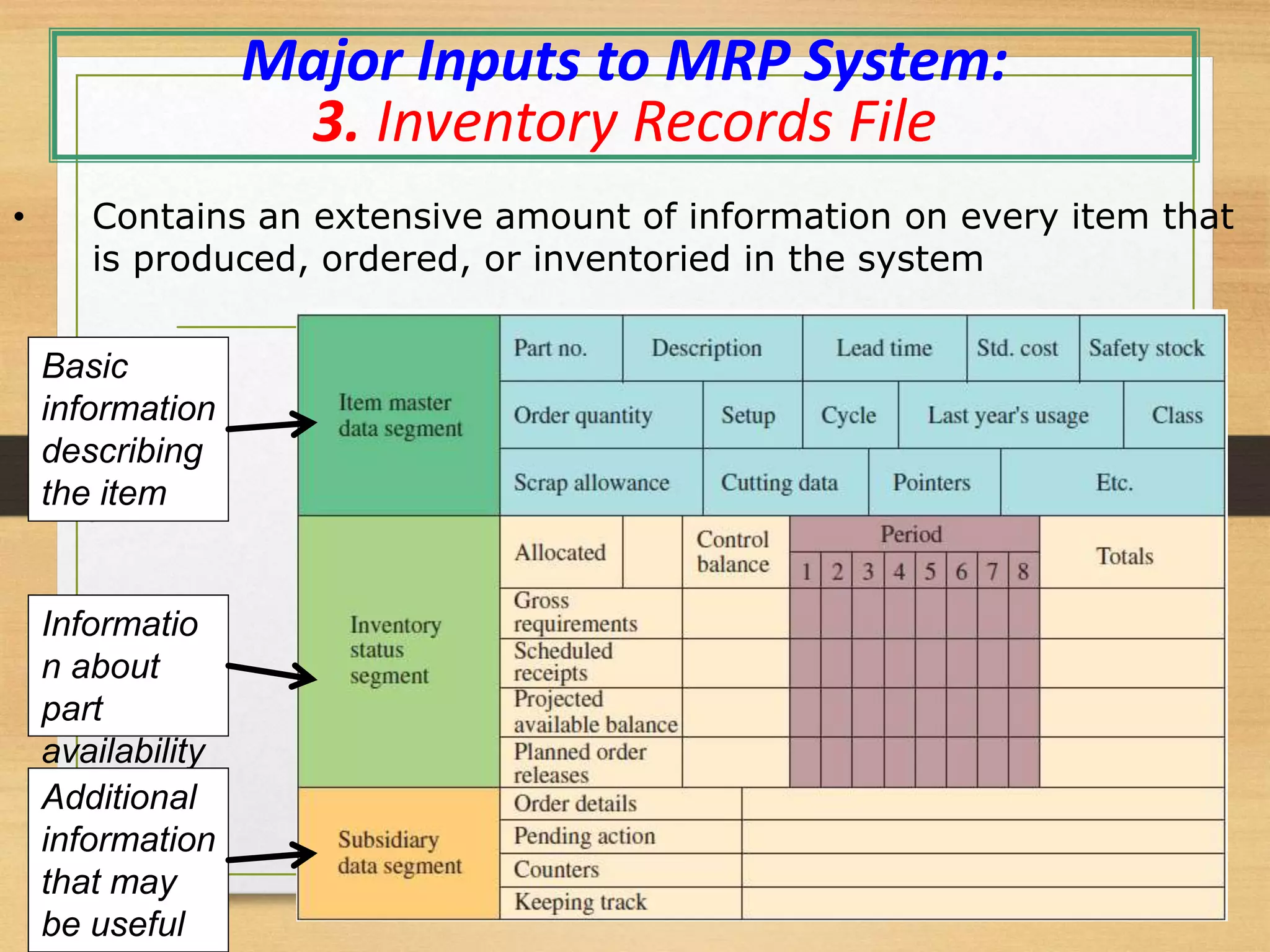

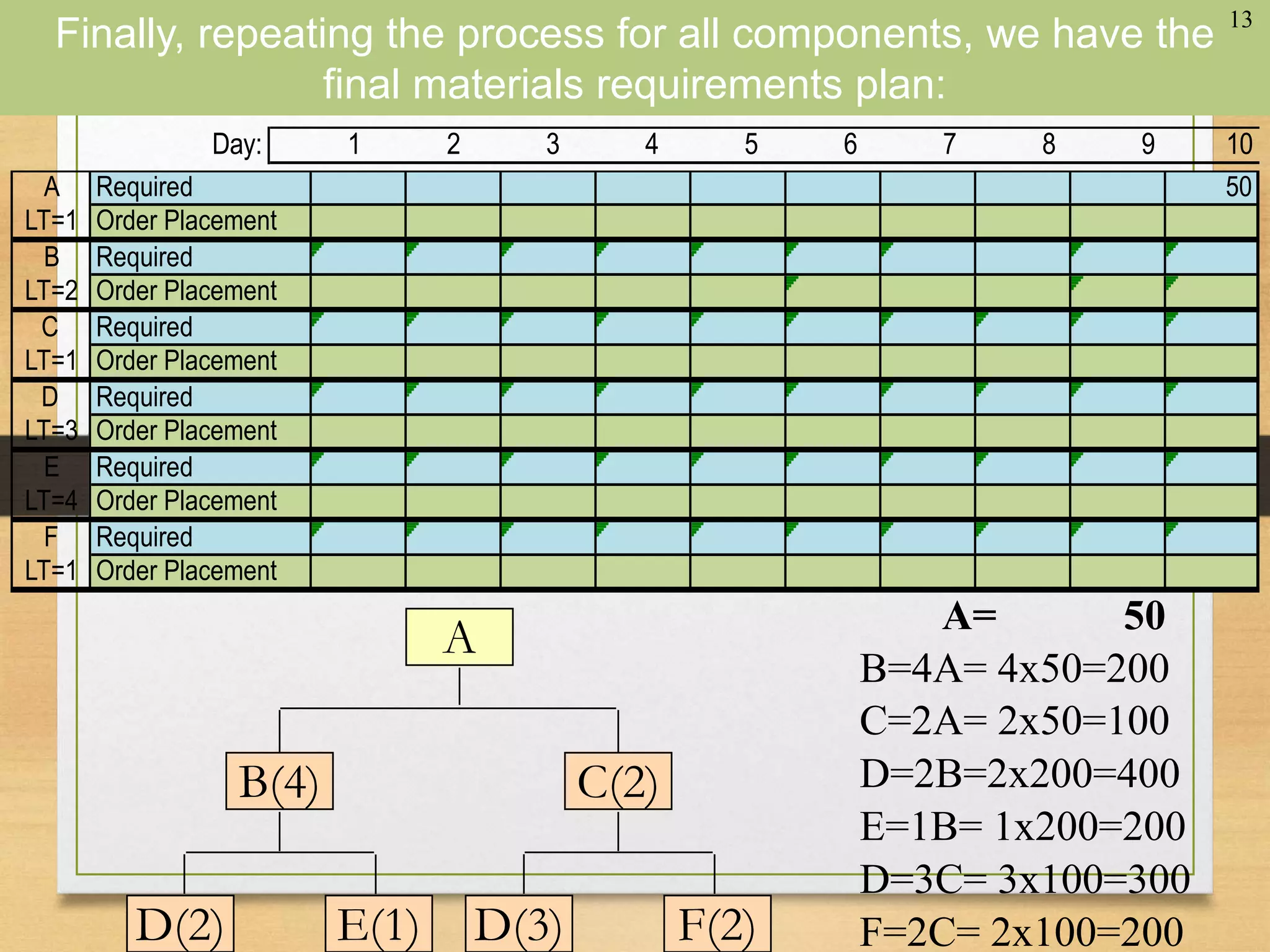

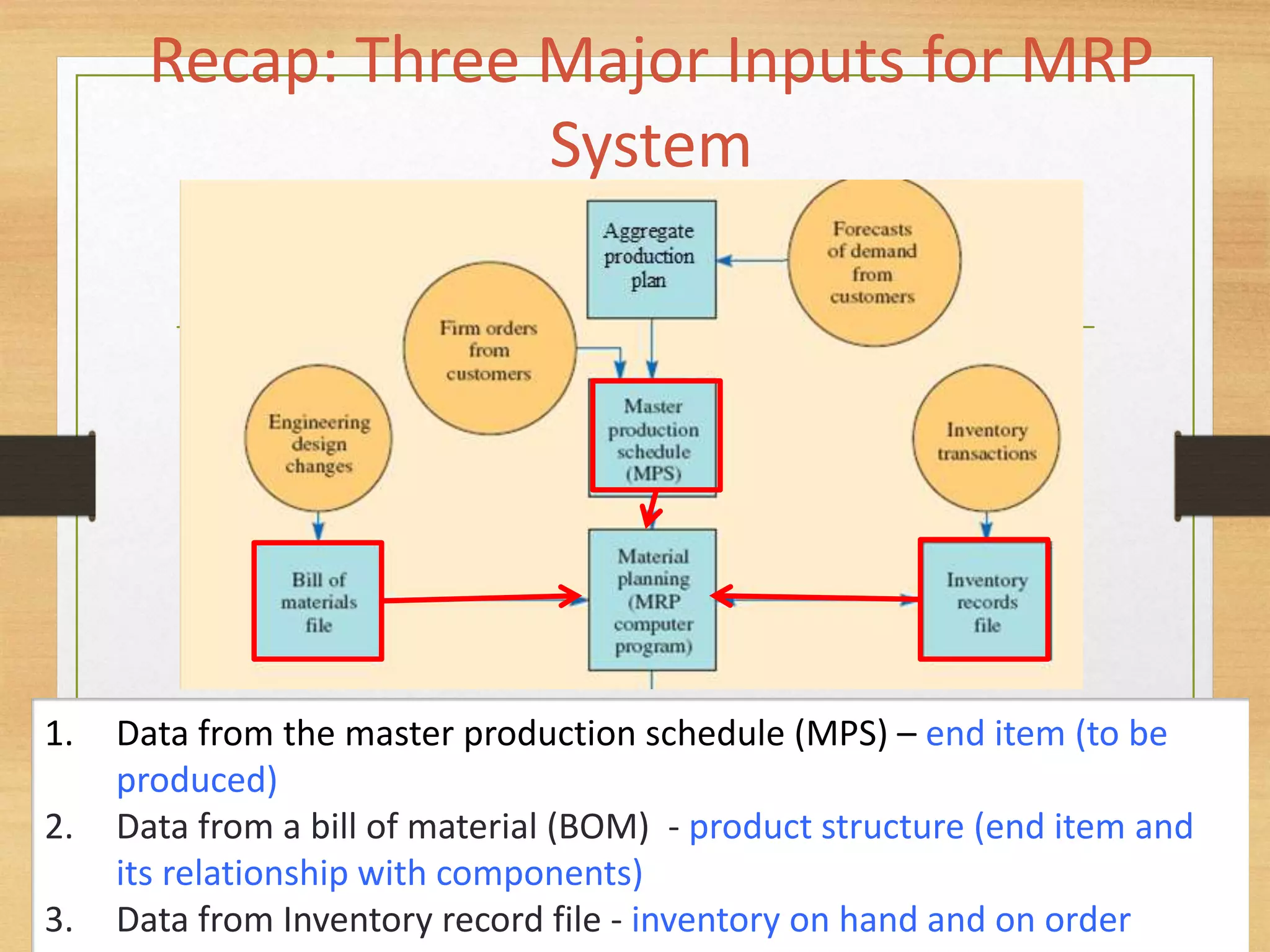

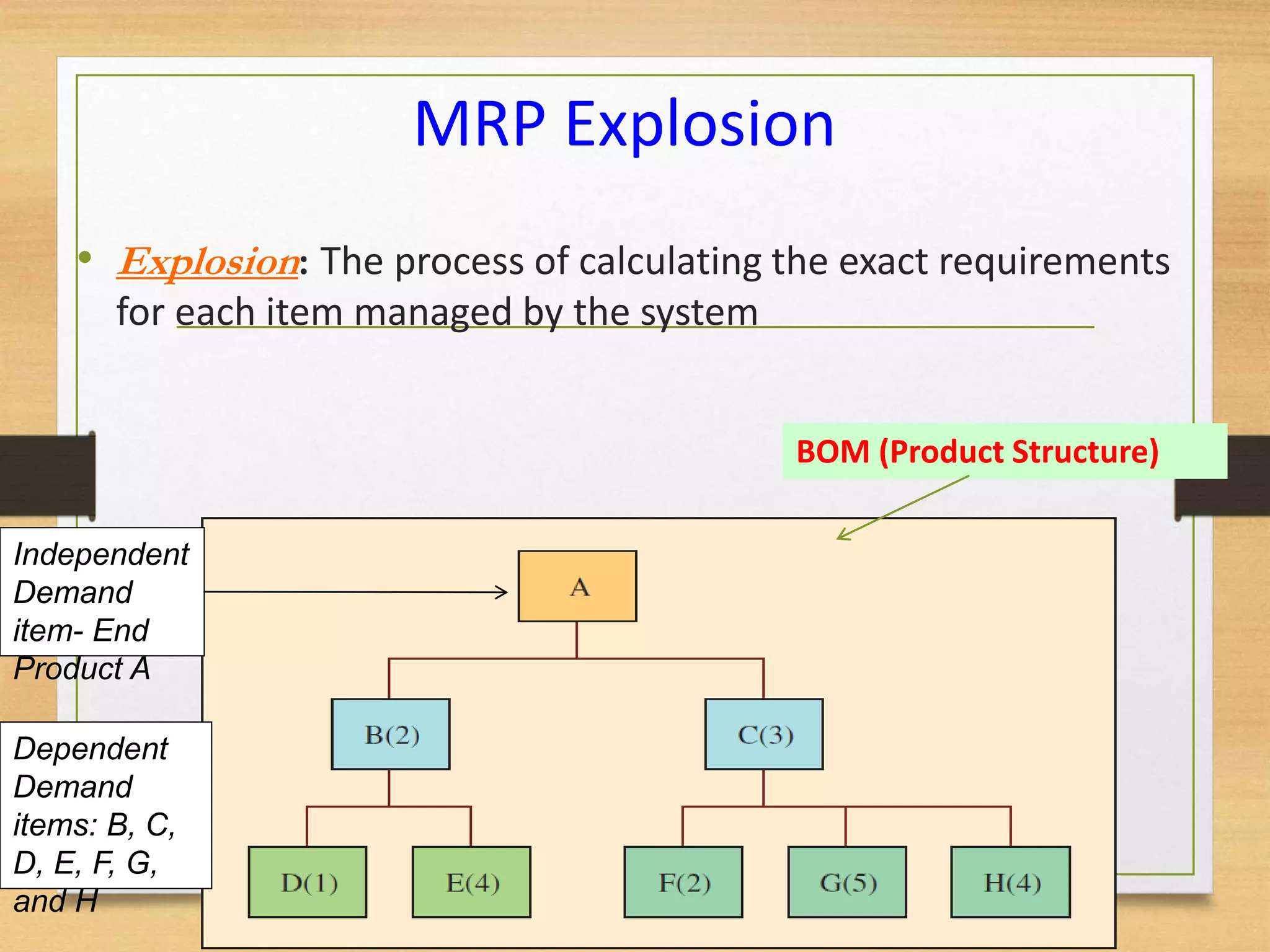

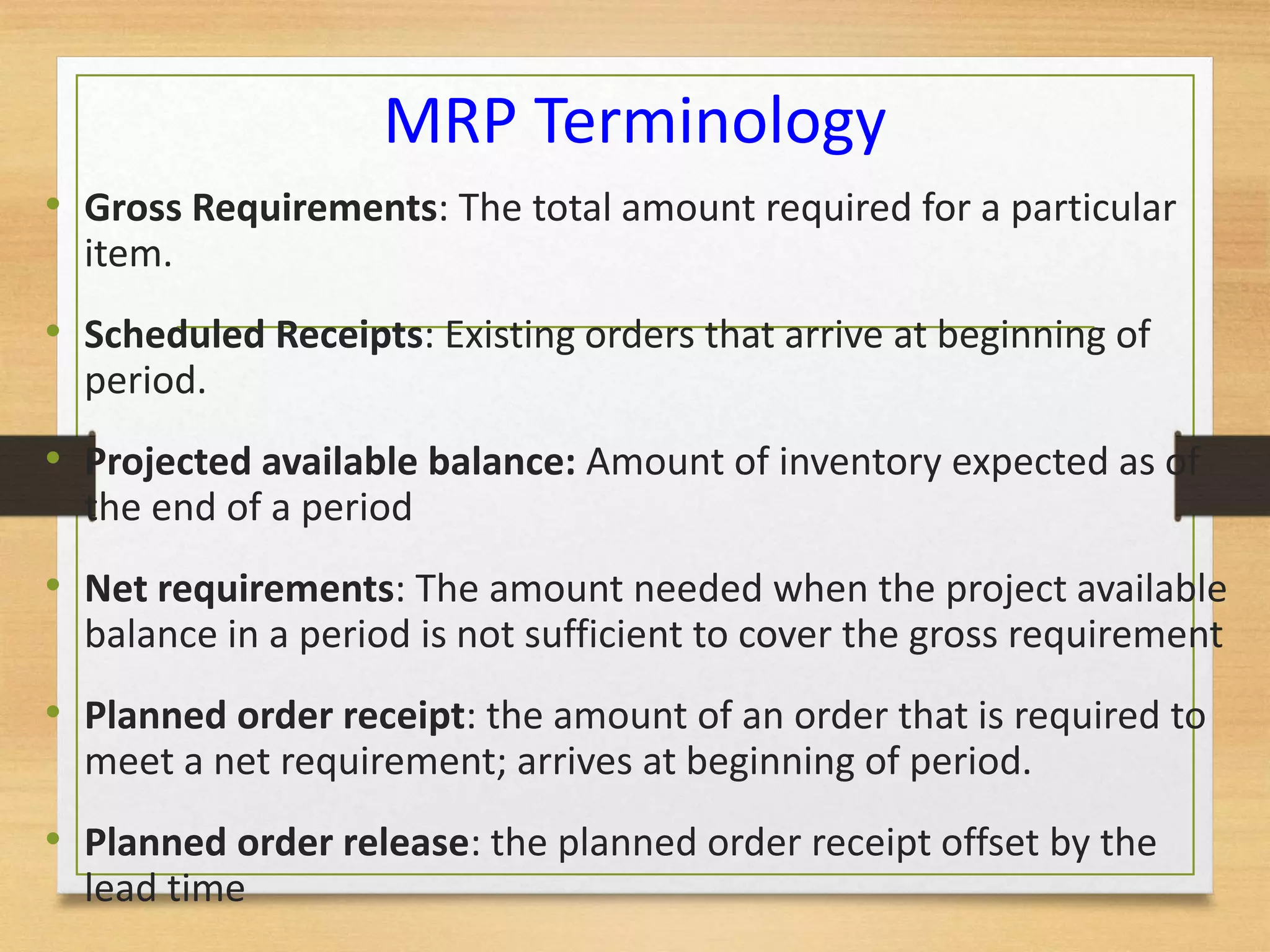

The document presents an overview of Material Requirements Planning (MRP) used at Kathmandu University School of Management, focusing on its structure, major inputs like the Master Production Schedule (MPS), Bill of Materials (BOM), and inventory records. It elaborates on the MRP logic, including calculations for component requirements and lead times while highlighting the differences between MRP and Just-In-Time (JIT) production systems. Additionally, the document emphasizes the dynamic nature of MRP and the importance of effective planning and scheduling in manufacturing processes.