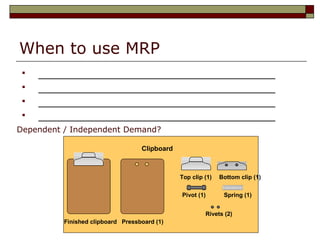

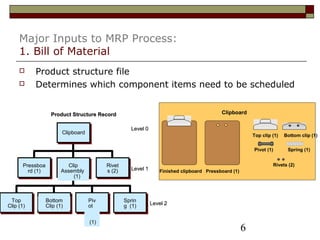

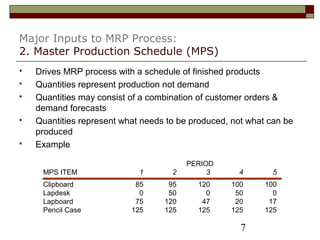

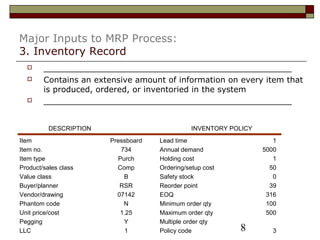

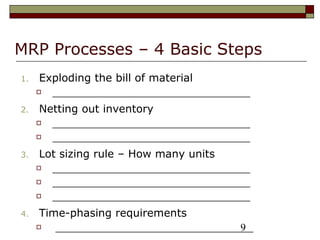

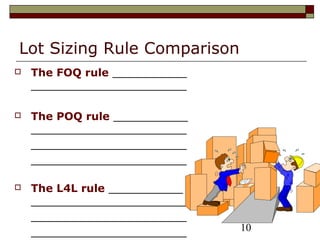

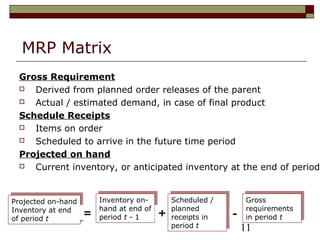

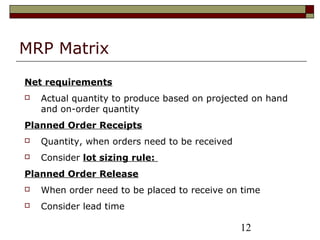

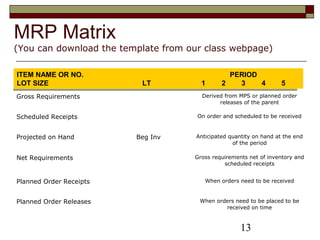

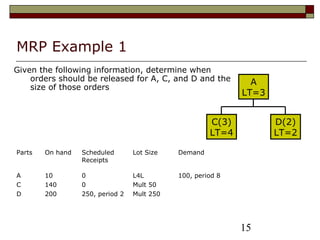

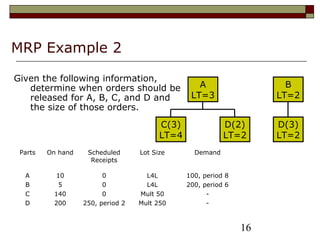

The document discusses material requirements planning (MRP). It describes the key outputs of MRP as calculating demand for component items, determining requirements for subassemblies and raw materials, determining when they are needed, and generating work orders and purchase orders while considering lead time. The document then provides details on when to use MRP, the major inputs to the MRP process including bills of material and master production schedules, the basic steps of MRP including exploding bills of material and netting inventory, lot sizing rules, and time-phasing requirements. Examples are also provided to illustrate how to use an MRP matrix to determine planned order releases and receipts.

![19

ERP Modules

[Figure 12.1 Organizational Data Flow]](https://image.slidesharecdn.com/37116mrpstudent1-130628033243-phpapp01/85/Planned-order-release-19-320.jpg)

![20

ERP Modules

[Figure 12.2 ERP’s Central Database]

Finance &

Accounting

Sales

&

Marketing

Human

Resources

Production &

Materials

Management

ERP Data

Repository](https://image.slidesharecdn.com/37116mrpstudent1-130628033243-phpapp01/85/Planned-order-release-20-320.jpg)