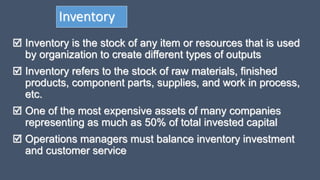

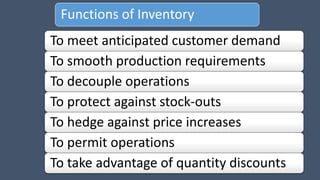

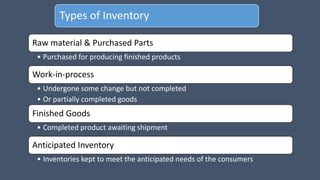

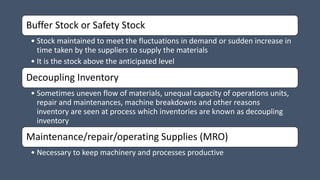

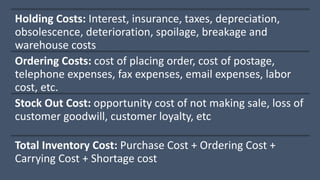

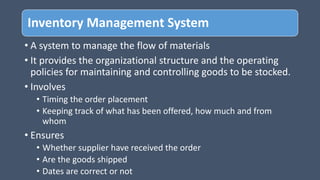

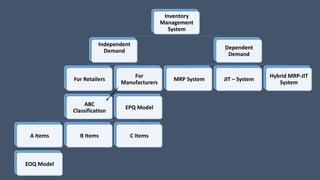

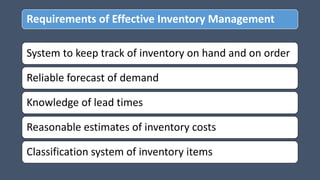

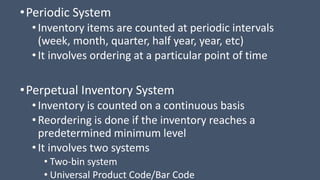

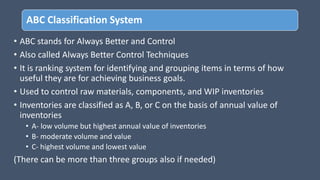

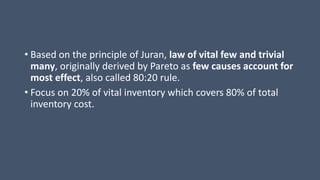

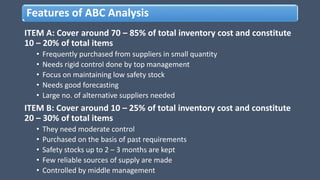

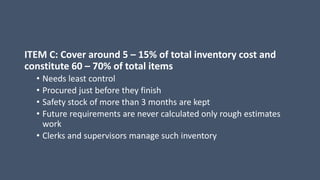

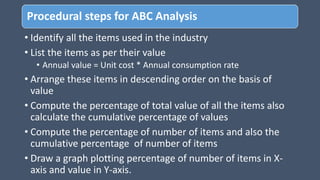

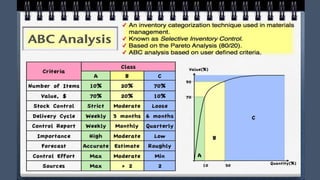

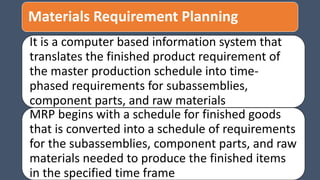

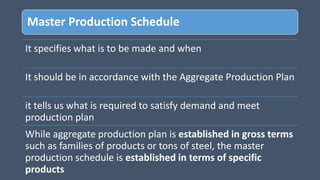

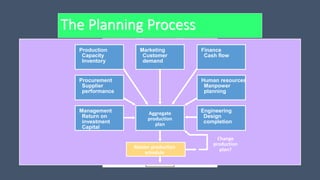

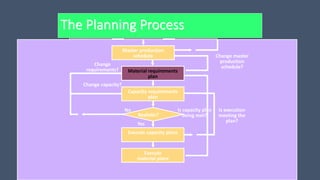

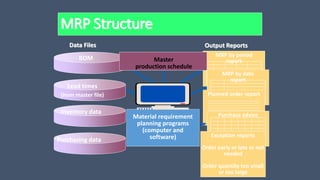

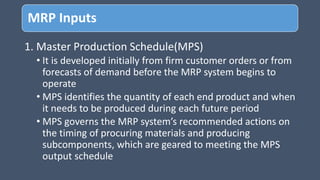

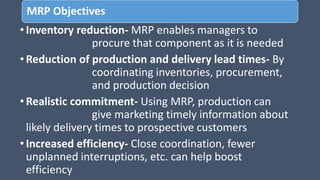

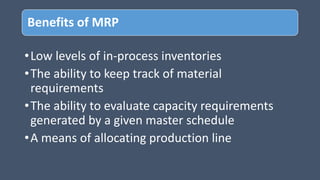

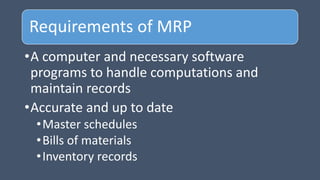

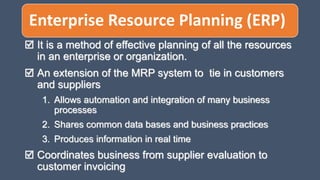

Inventory management involves tracking and controlling a company's stock of raw materials, work-in-progress, and finished goods. Effective inventory management requires balancing inventory investment with customer service levels. Key aspects of inventory management include classifying inventory using techniques like ABC analysis, planning inventory needs using models like MRP, and controlling inventory through periodic or perpetual counting systems. The overall goal is meeting customer demand while minimizing total inventory costs.