Embed presentation

Download to read offline

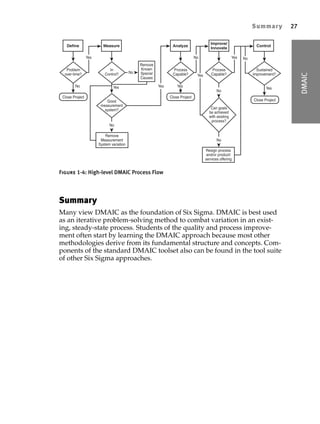

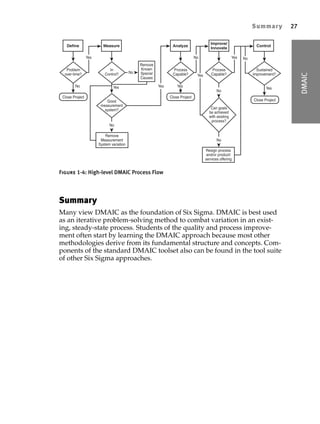

The document provides an overview of the Define-Measure-Analyze-Improve-Control (DMAIC) methodology, which is Six Sigma's most common problem-solving approach. It consists of five steps: Define the problem, Measure current performance, Analyze to find the root cause, Improve by implementing a solution, and Control to ensure continued benefits. The approach aims to reduce variation and bring processes back into alignment with customer requirements. Key requirements that determine the methodology's activities include understanding the problem definition, current metrics and their trends, identifying root causes, implementing corrective actions, and controlling improvements over time.