Quality Engineering material

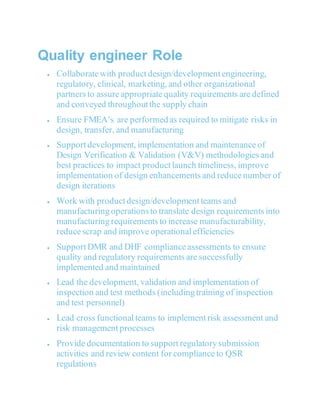

- 1. Quality engineer Role Collaborate with product design/development engineering, regulatory, clinical, marketing, and other organizational partners to assure appropriate quality requirements are defined and conveyed throughout the supply chain Ensure FMEA’s are performed as required to mitigate risks in design, transfer, and manufacturing Support development, implementation and maintenance of Design Verification & Validation (V&V) methodologies and best practices to impact product launch timeliness, improve implementation of design enhancements and reduce number of design iterations Work with product design/development teams and manufacturing operationsto translate design requirements into manufacturing requirements to increase manufacturability, reduce scrap and improve operational efficiencies Support DMR and DHF compliance assessments to ensure quality and regulatory requirements are successfully implemented and maintained Lead the development, validation and implementation of inspection and test methods (including training of inspection and test personnel) Lead cross functional teams to implement risk assessment and risk management processes Provide documentation to support regulatory submission activities and review content for compliance to QSR regulations

- 2. Participate in cross functional teams to review and evaluate impact of proposed supplier changes Provide support to complaint management and post market surveillance organization by completing robust and timely complaint investigations Develop, coordinate and perform technical reliability studies and evaluations of engineering design concepts and design of experiments (DOE) Develop statistical process control methodologies to achieve required levels of product reliability Analyze quality performance indicator data and investigate adverse trends to identify variables that may potentially affect product and processes Identify opportunities to implement design changes to improve system and/or process reliability, reduce scrap rates and improve yields and efficiencies Serve as Subject Matter Expert for regulatory inspections related to Design Controls, Process Validation, Device Master Records and Design History Files ESSENTIAL DUTIES and RESPONSIBILITIES in Manufacturing Engineering 1. Collaborate with Res customers’ quality and engineering personnel to determine critical part features and review manufacturability of design. Make recommendations to modify customer part specifications and tolerances as necessary to support cost effective production. 2. Provide engineering support to operations ensuring consistent application of quality techniques 1. Resolve quality issues of capability, tolerancing, and materials related issues.

- 3. 2. Resolve quality issues by identifying problems, examining solution options, implementing action plans, and providing resources. 3. Effectively communicate and reinforce Res’ commitment to quality improvement efforts 3. Develop and submit PPAP documents for new product lunches to meet customer requirements. 4. Determine when process stability and capability studies should be performed on existing processes. Review and analyze results. Recommend changes to processes based upon findings and perform follow up to verify effectiveness. 5. Participate in the Advanced Product Quality Planning activities to determine appropriate use of existing and new measurement systems during new tool or process design and startup. 6. Coordinate pre-launch production trial run process monitoring. 7. Participate in the development of Failure Mode and Effects Analysis (FMEA). 8. Maintain Control Plans and FMEA's throughout the life of the part. 9. Facilitate and promote use of appropriate problem solving techniques for effective root cause analysis and successful corrective action. Perform duties in accordance with quality system requirements as the voice of Res' customers. Coordinate with Sales, Purchasing, Engineering, Production, and Toolroom to resolve customer complaints and concerns. Lead PPM improvement plan for strategic customers. 1. Apply appropriate use of statistical techniques. 2. Determine and apply appropriate Measurement System Analysis tools. Quadratic loss function[edit] The use of a quadratic loss function is common, for example when using least squares techniques. It is often more mathematically tractable than other loss functions because of the properties of variances, as well as being symmetric: an error above the target causes the same loss as the same magnitude of error below the target. If the target is t, then a quadratic loss function is for some constant C; the value of the constant makes no difference to a decision, and can be ignored by setting it equal to 1.

- 4. Many common statistics, including t-tests, regression models, design of experiments, and much else, use least squares methods applied using linear regression theory, which is based on the quadratic loss function. The quadratic loss function is also used in linear-quadratic optimal control problems. In these problems, even in the absence of uncertainty, it may not be possible to achieve the desired values of all target variables. Often loss is expressed as a quadratic form in the deviations of the variables of interest from their desired values; this approach is tractable because it results in linear first-order conditions. In the context of stochastic control, the expected value of the quadratic form is used. Designing the Experiment When you decide you are going to conduct a experiment the first thing that you should do is design it in way that it can test your hypothesis. When developing the design of a experiment there is certain criteria to consider. Helpful tips for Designing an Experiment: 1. You should define the essential design components which are: 2. operational definition of the independent and dependent variables 3. what factors are kept constant 4. the levels of the independent variable selected for the investigation 5. a description of the investigation that you will follow 6. a description of the trials you may want to conduct 7. and a control so you have something to compare it to Make sure your procedure of the experiment you write is clear enough, you can check for clarity by having someone else your procedure and see if they could follow it. Conducting the Experiment Here are the steps to ensure accuracy when running a experiment: answering questions identifying variables developing hypotheses finding the factors to be kept constant creating operational definitions

- 5. designing a investigation repeating trials as necessary collecting data and interpreting it making conclusions