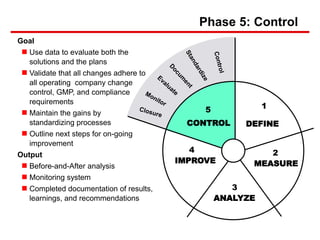

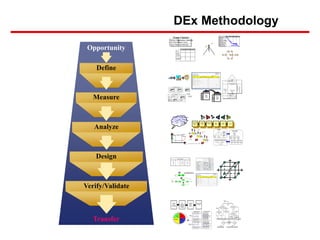

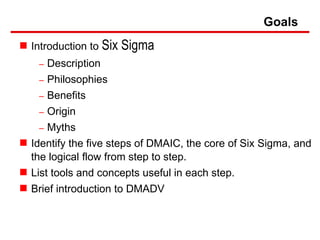

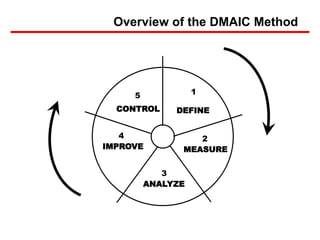

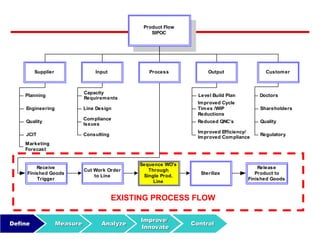

Six Sigma is a data-driven approach to process improvement that aims to reduce defects. It uses statistical methods and the DMAIC framework (Define, Measure, Analyze, Improve, Control) to identify and address root causes of defects. The document provides an overview of Six Sigma, including its goals of reducing costs and improving customer experience. It also describes the five steps of DMAIC and some of the tools used in each step, such as process mapping in Define and data collection/analysis in Measure and Analyze to identify problems and root causes.

![Design of Experiment

AnalyzeMeasure Improve ControlDefine

Hi

Lo0.00000

D

New

Cur

d = 0.00000

Maximum

Burst Va

y = 94.6429

2.0

3.0

55.0

90.0

245.0

260.0

Pressure TimeTemp

[245.0] [75.0] [3.0]](https://image.slidesharecdn.com/dmaic-150818162610-lva1-app6891/85/Dmaic-24-320.jpg)