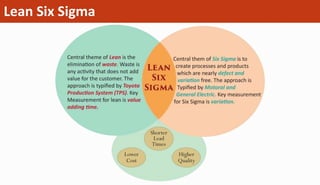

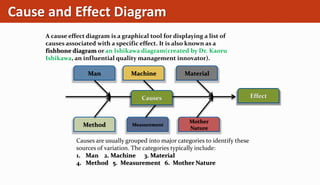

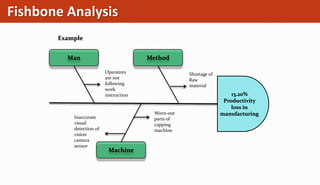

Six Sigma is a data-driven approach and methodology for process improvement originally developed by Motorola. It aims to reduce defects and variation in manufacturing and business processes. The document discusses the history and key aspects of Six Sigma such as the DMAIC approach, tools used in each phase like process mapping, root cause analysis, and improvement techniques like 5S, poka-yoke, and FMEA. Implementing Six Sigma through the DMAIC approach can help organizations optimize processes and improve quality, productivity, and customer satisfaction.