This document provides an overview of Six Sigma, including:

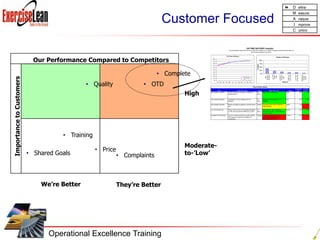

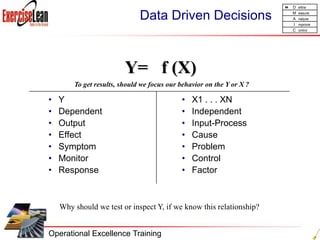

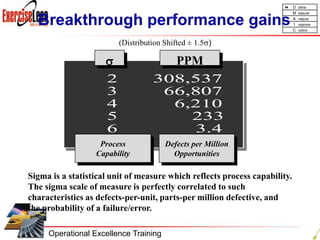

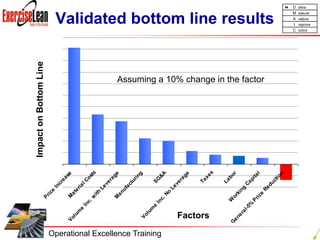

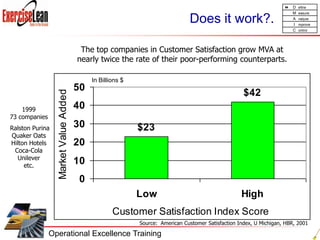

1) Six Sigma is a data-driven, customer-focused methodology for achieving breakthrough performance gains and validated bottom line results through reducing variation and defects in processes.

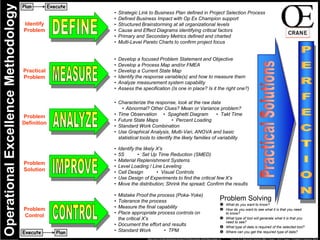

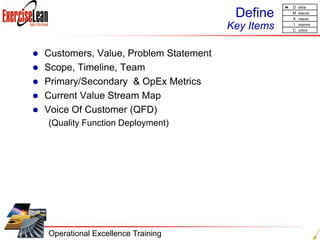

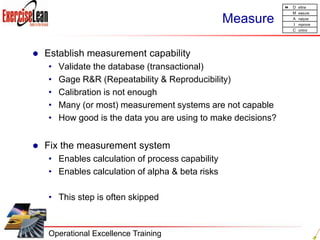

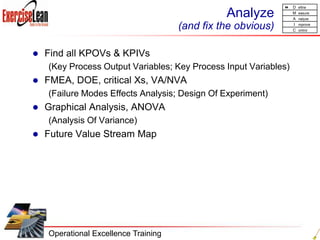

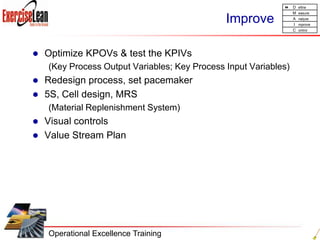

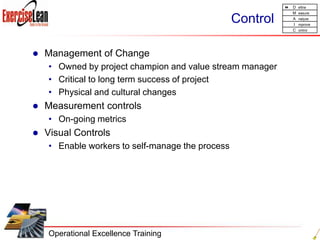

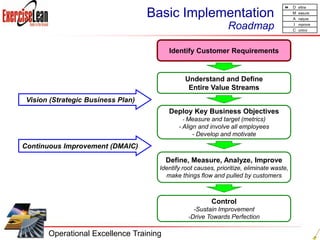

2) The Six Sigma methodology follows the DMAIC process of Define, Measure, Analyze, Improve, and Control.

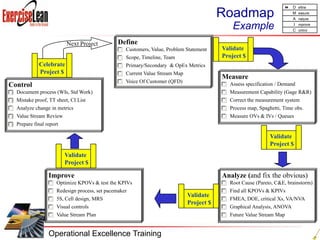

3) An example roadmap is provided that outlines how to apply the Six Sigma DMAIC process to a project to achieve strategic business objectives.