This document discusses several quality management experts and their contributions:

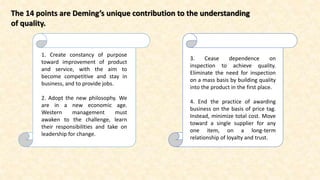

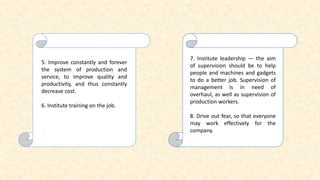

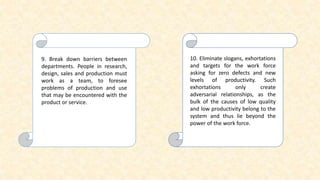

- W. Edwards Deming emphasized that quality issues often stem from management failures like lack of planning. He developed the famous 14 Points for quality management.

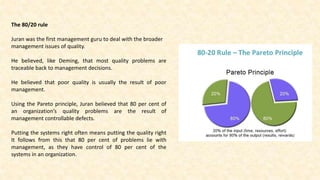

- Joseph Juran developed the concept of the "quality trilogy" of planning, control, and improvement. He also introduced the 80/20 rule about quality problems.

- Tom Peters stressed the importance of leadership and customer focus for quality. He outlined 12 attributes of successful quality programs.

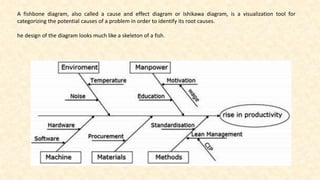

- Kaoru Ishikawa promoted quality circles and company-wide participation in quality. He also developed tools like cause-and-effect diagrams.