The document discusses production management and factors related to plant location. It covers:

1) The conversion of raw materials into finished goods using processes, machines, tools and workers is known as production. Production management deals with efficient production planning and control.

2) Key considerations for plant location include availability of raw materials, labor, markets, transportation and utilities at minimum cost. Location analysis involves evaluating domestic and international sites based on these factors.

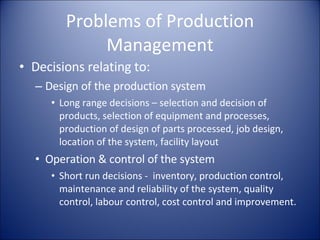

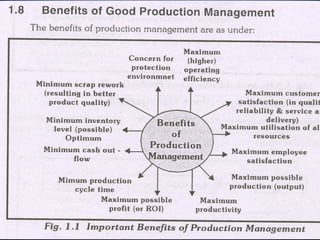

3) Production managers are responsible for production planning, quality control, inventory management and ensuring optimal resource utilization to meet production goals. Their decisions involve facilities design, operations, maintenance and cost control.