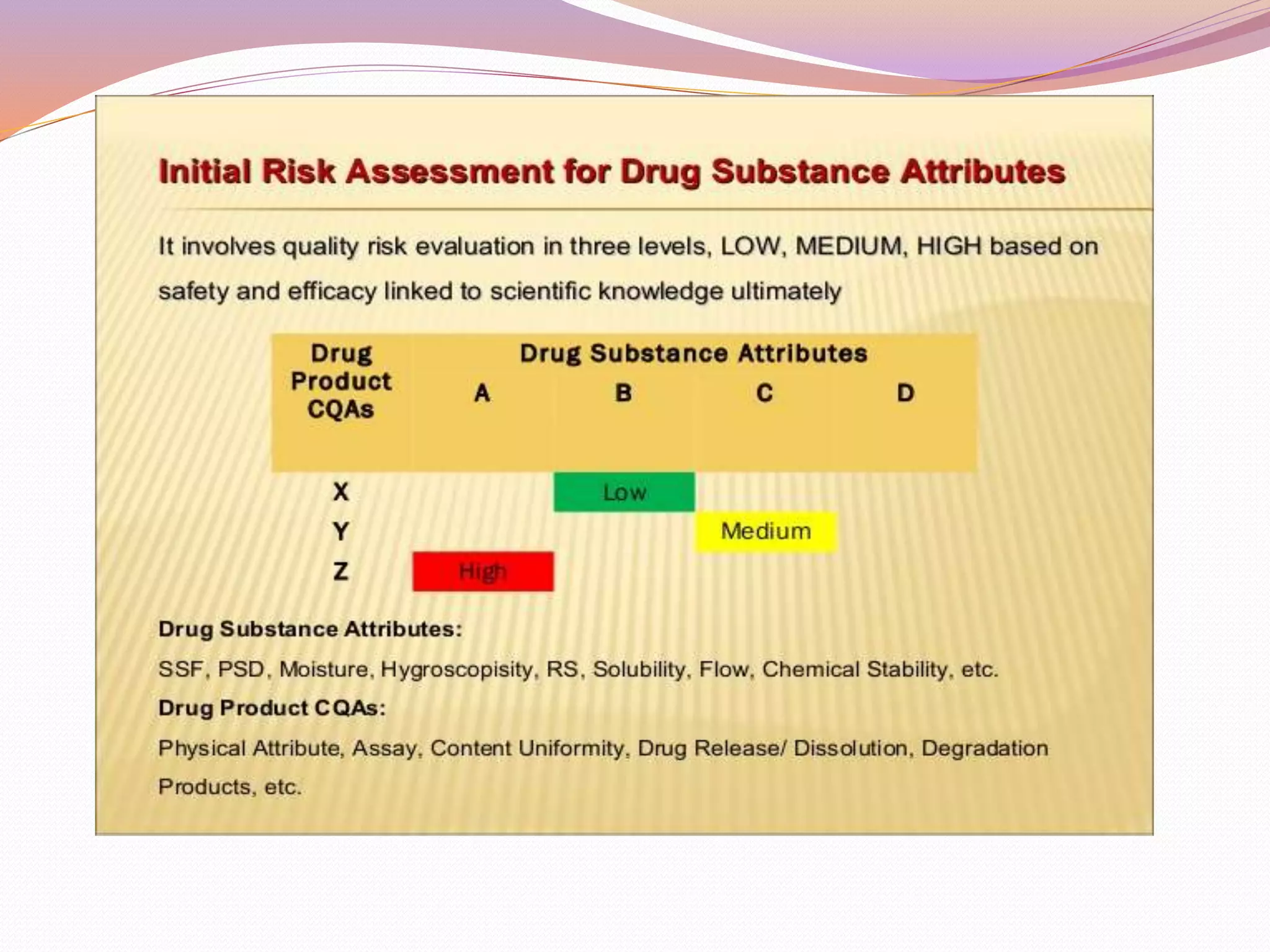

This presentation introduces Quality by Design (QbD) for pharmaceutical formulation and development. QbD requires understanding how formulation and process variables impact product quality to ensure predefined quality. The benefits of QbD include eliminating batch failures, minimizing deviations, and avoiding regulatory issues. For formulation and development, QbD involves establishing a quality target product profile, identifying critical quality attributes, conducting a risk assessment of drug substance and formulation attributes, developing an initial formulation, using design of experiments for optimization, establishing a control strategy, conducting pilot bioequivalence studies, and scale up with supporting stability studies.