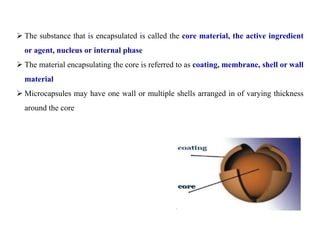

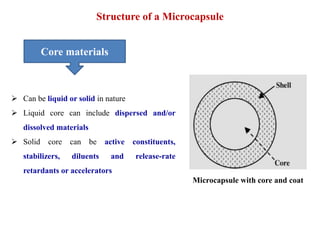

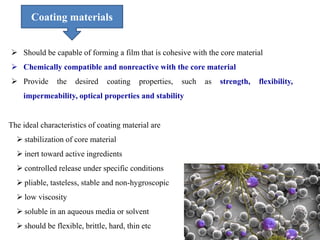

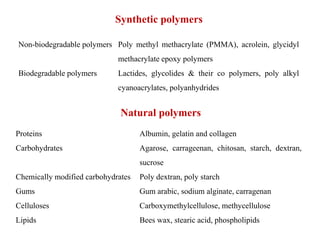

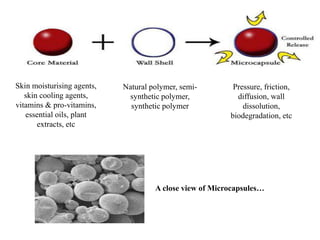

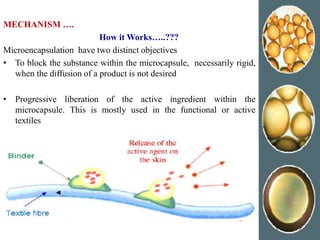

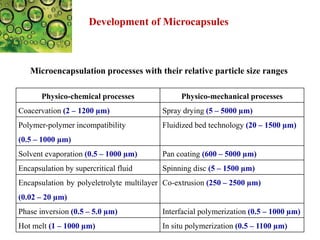

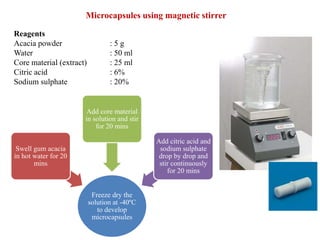

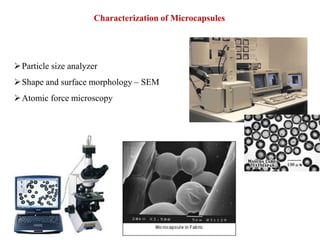

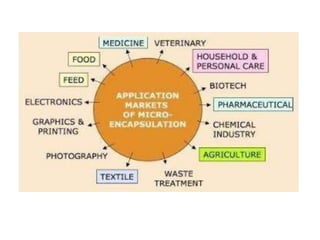

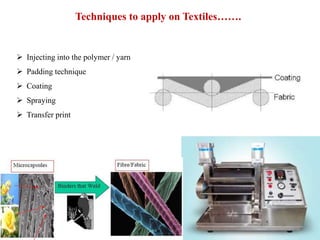

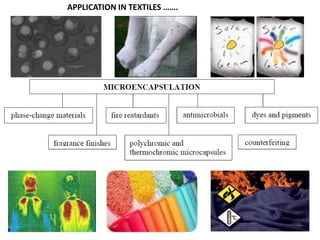

Microencapsulation is a process where tiny particles or droplets are surrounded by a coating to form capsules ranging from less than 1 micron to several hundred microns. The core material is encapsulated within the coating material and can be released through mechanisms like dissolution, degradation, or diffusion. Microencapsulation has applications in textiles to provide properties like controlled release of active ingredients over multiple washes. Common techniques for developing microcapsules include coacervation, spray drying, and solvent evaporation. Microcapsules are characterized using tools like particle size analysis, SEM, and AFM.