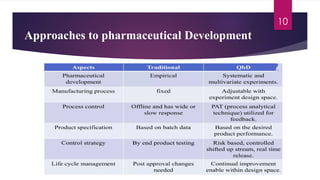

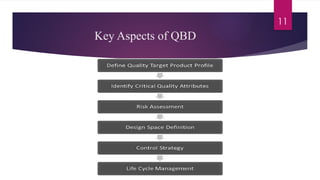

"This document provides a comprehensive overview of Quality by Design (Qbd), a modern approach in pharmaceutical development focused on designing quality into products from the initial stages. It highlights key principles such as critical quality attributes (CQAs), design of experiments (DoE), and risk assessment tools, ensuring regulatory compliance and consistent product performance."