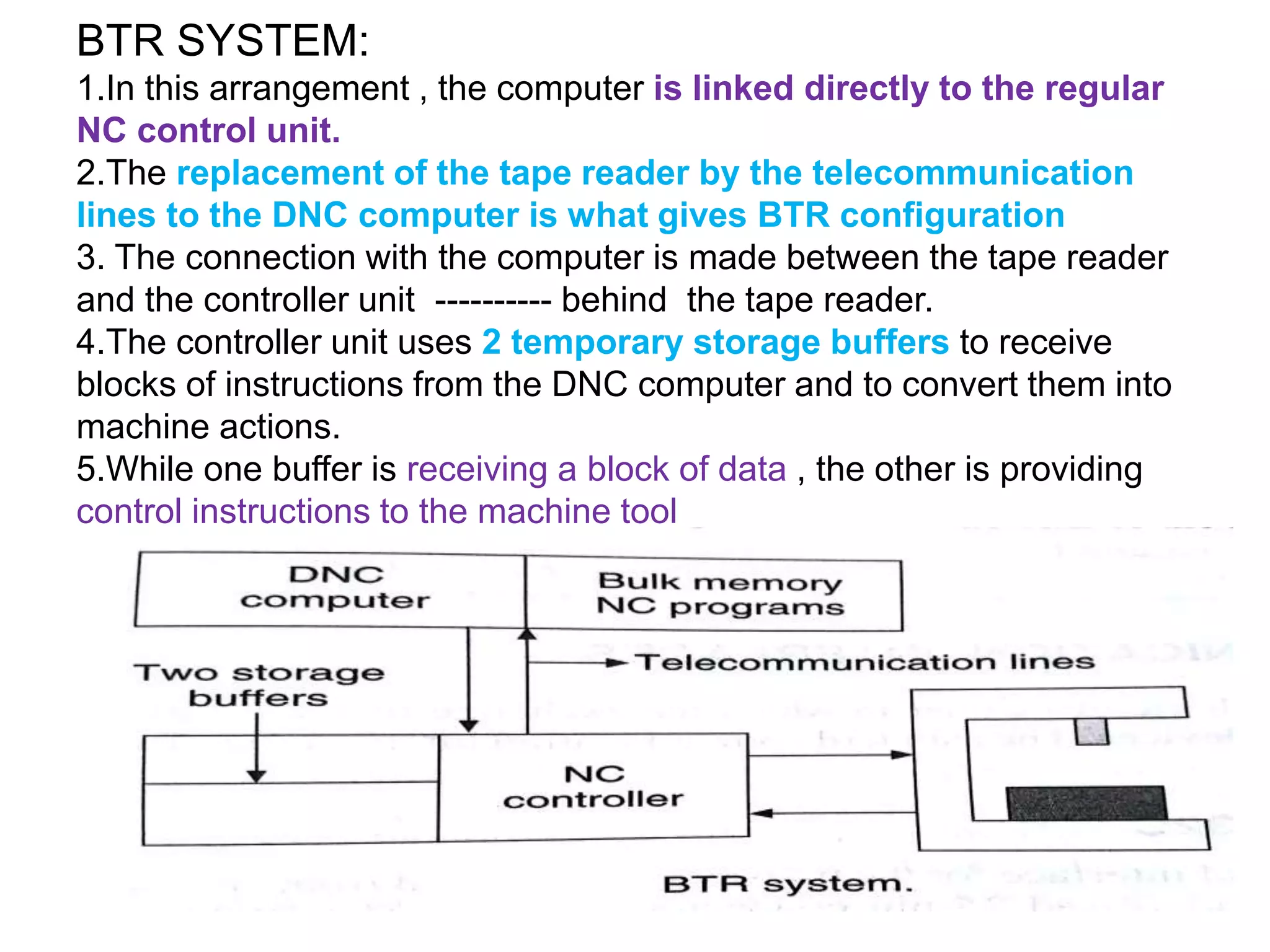

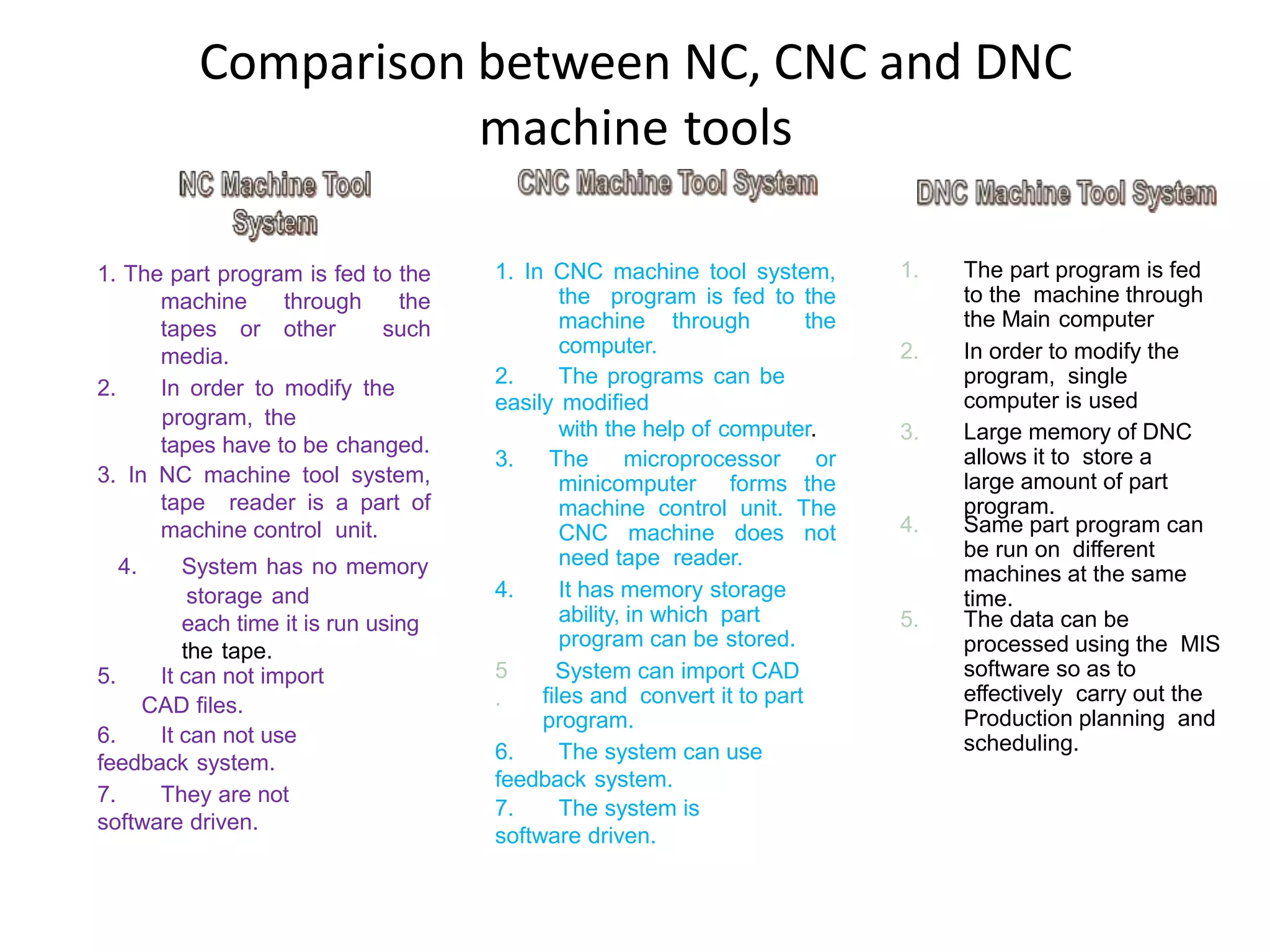

The document discusses DNC (Direct Numerical Control) systems that connect multiple NC machines to a central computer for real-time control, storage, and program management, eliminating the need for punched tape. It outlines the advantages, such as ease of programming and data collection, along with limitations like higher costs and the need for specialized operators. DNC systems can enhance communication between machine tools and the central computer, providing an efficient solution for modern manufacturing processes.