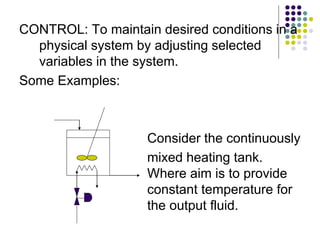

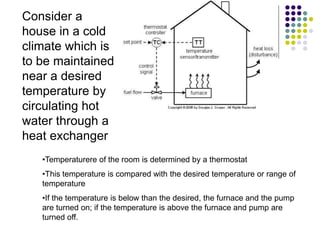

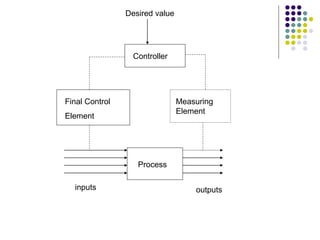

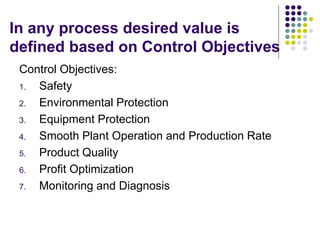

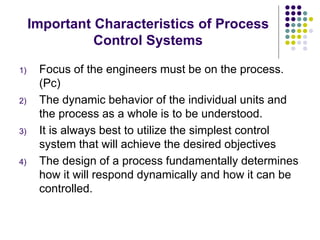

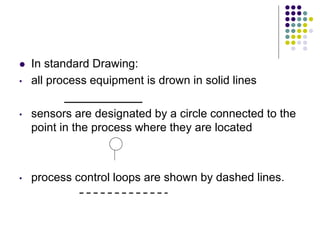

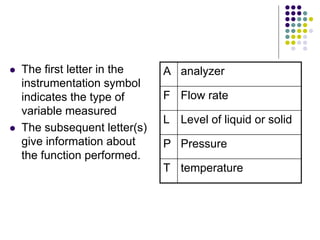

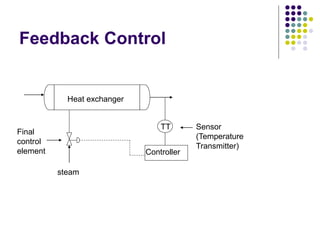

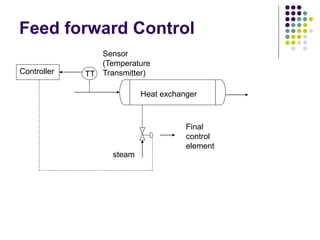

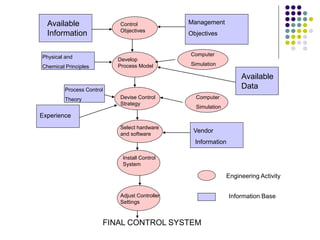

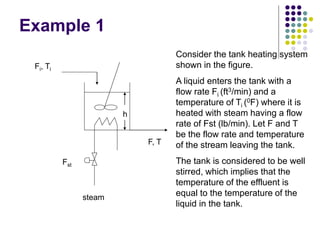

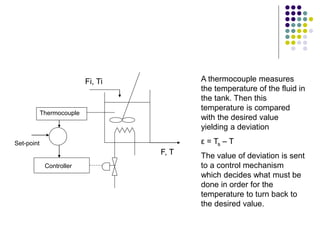

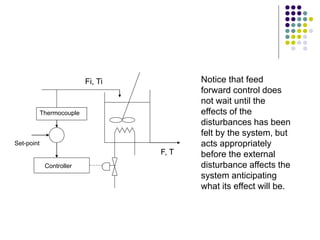

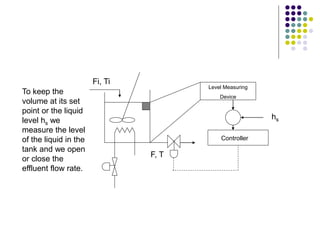

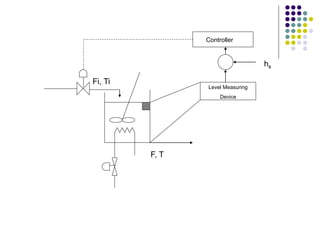

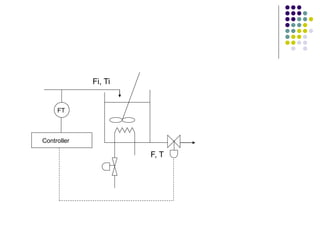

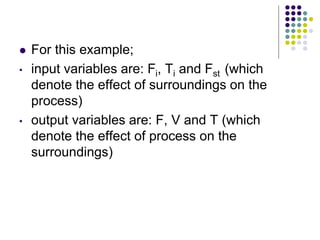

The document discusses process control and control systems. It defines control as maintaining desired conditions in a system by adjusting variables. Control is necessary to maintain variables when disturbances occur and to respond to changes in desired values. For control to be possible, the process must be designed so it responds well dynamically. Control systems use measurements from sensors to calculate adjustments to manipulated variables via controllers and final control elements. The document outlines various control strategies and characteristics of effective control systems.