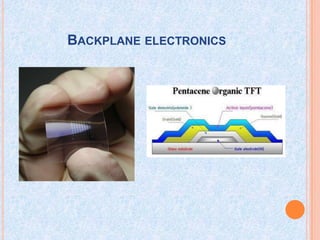

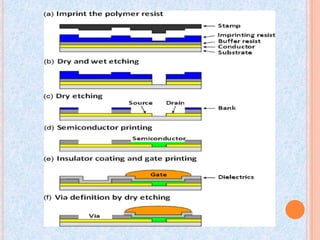

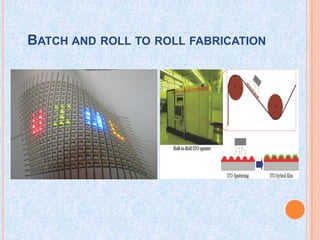

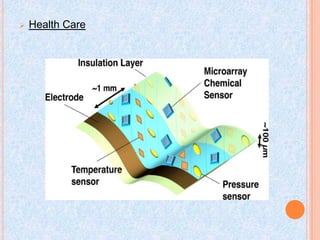

This document discusses flexible electronics. It begins with an introduction to advances in thin-film materials and devices that have enabled developments in flexible electronics. It then outlines various materials used in flexible electronics like substrates, backplane electronics, frontplanes and encapsulation. It discusses technologies involved in processing flexible electronics like batch and roll-to-roll fabrication. The document covers applications in various fields like healthcare, displays, energy and more. It concludes by discussing advantages like size/weight reductions and increased circuitry density, while noting limitations like lifetime and manufacturing challenges.