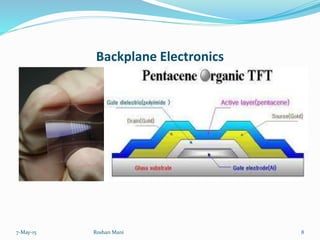

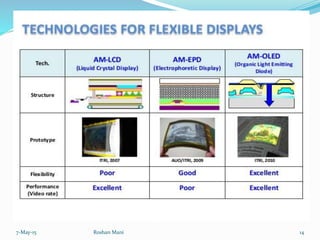

This document discusses flexible electronics and OLED displays. It begins with an introduction to advances in thin-film materials and flexible electronics. It then covers the basic OLED structure, materials used including substrates and backplane electronics, and technologies for flexible displays. The document discusses fabrication methods like batch and roll-to-roll processing. It outlines applications in areas like healthcare, automotive, and displays. Advantages of flexible electronics are listed as well as limitations that need to be addressed.