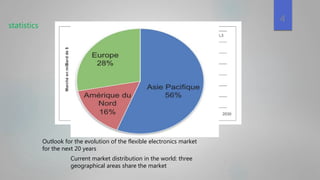

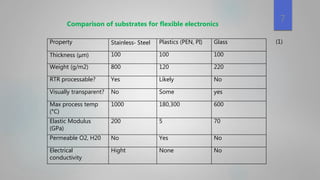

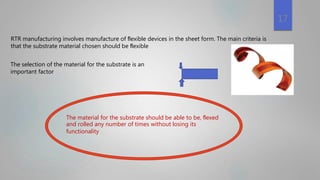

Flexible electronics is a technology where electronic circuits are assembled on flexible substrates to create devices that are thin, light, portable, and flexible. Researchers are working to develop flexible electronics in various fields. Roll-to-roll processing allows continuous fabrication of flexible devices using deposition, etching, printing, and other techniques. Applications include wearables, healthcare devices, mobile electronics, and automotive electronics. Challenges remain in improving materials, yields, lifetimes, and encapsulation of flexible electronic devices.