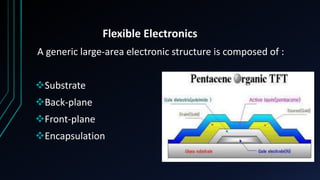

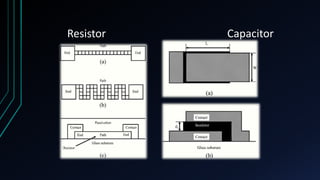

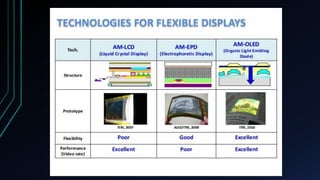

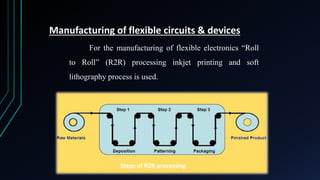

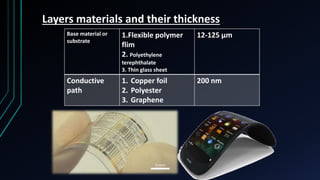

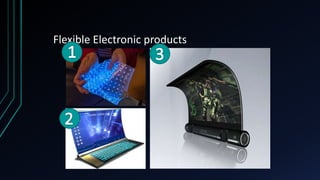

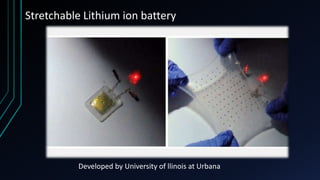

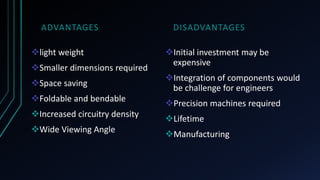

The presentation discusses flexible electronics, highlighting their construction on flexible substrates and various fabrication techniques. It covers market growth predictions, applications across various fields, advantages such as lightweight design, and challenges including high initial investment. The conclusion emphasizes a significant future demand for flexible electronics in sectors like security and entertainment.

![References

• [1] www.wikkipedia.org.in/flexibleelectronics

• [2] "Printed Circuit Techniques" by Cledo Brunetti and Roger W. Curtis (National

Bureau of Standards Circular 468 first issued 15 November 1947)

• [3] Gleskova, H., Wagner, S., Gasˇpar k, V. & Kova´cˇ, P. 150uC Amorphous

Silicon thin-Film Transistor technology for Polyimide Substrates. J.Electrochem.

Soc.148, G370-G374 (2001)

• [4] Cotema, coating machinery GmbH www.cotema.de](https://image.slidesharecdn.com/flexibleec-170326111904/85/Flexible-Electronics-PPT-by-Sourabh-Kumar-24-320.jpg)