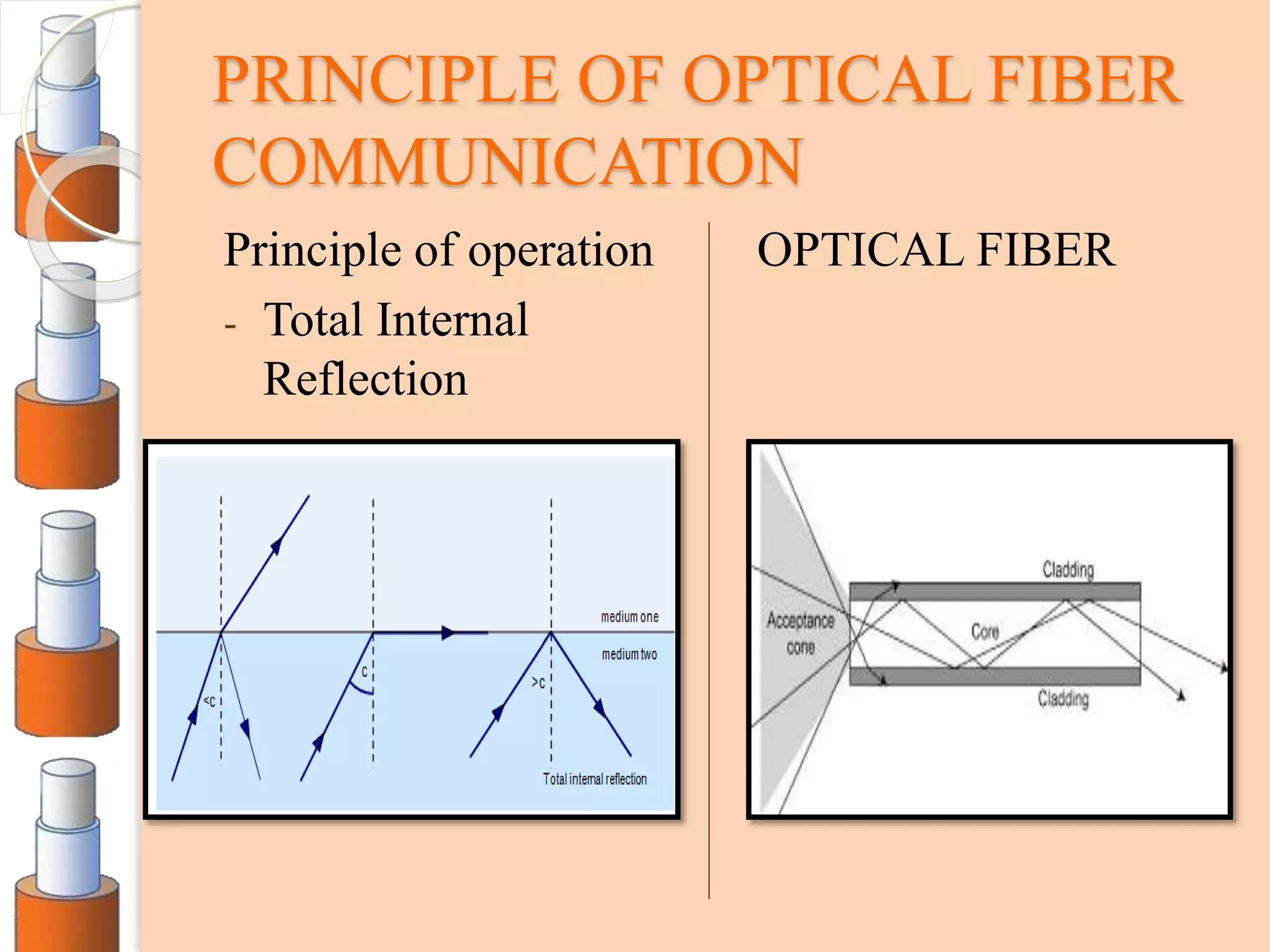

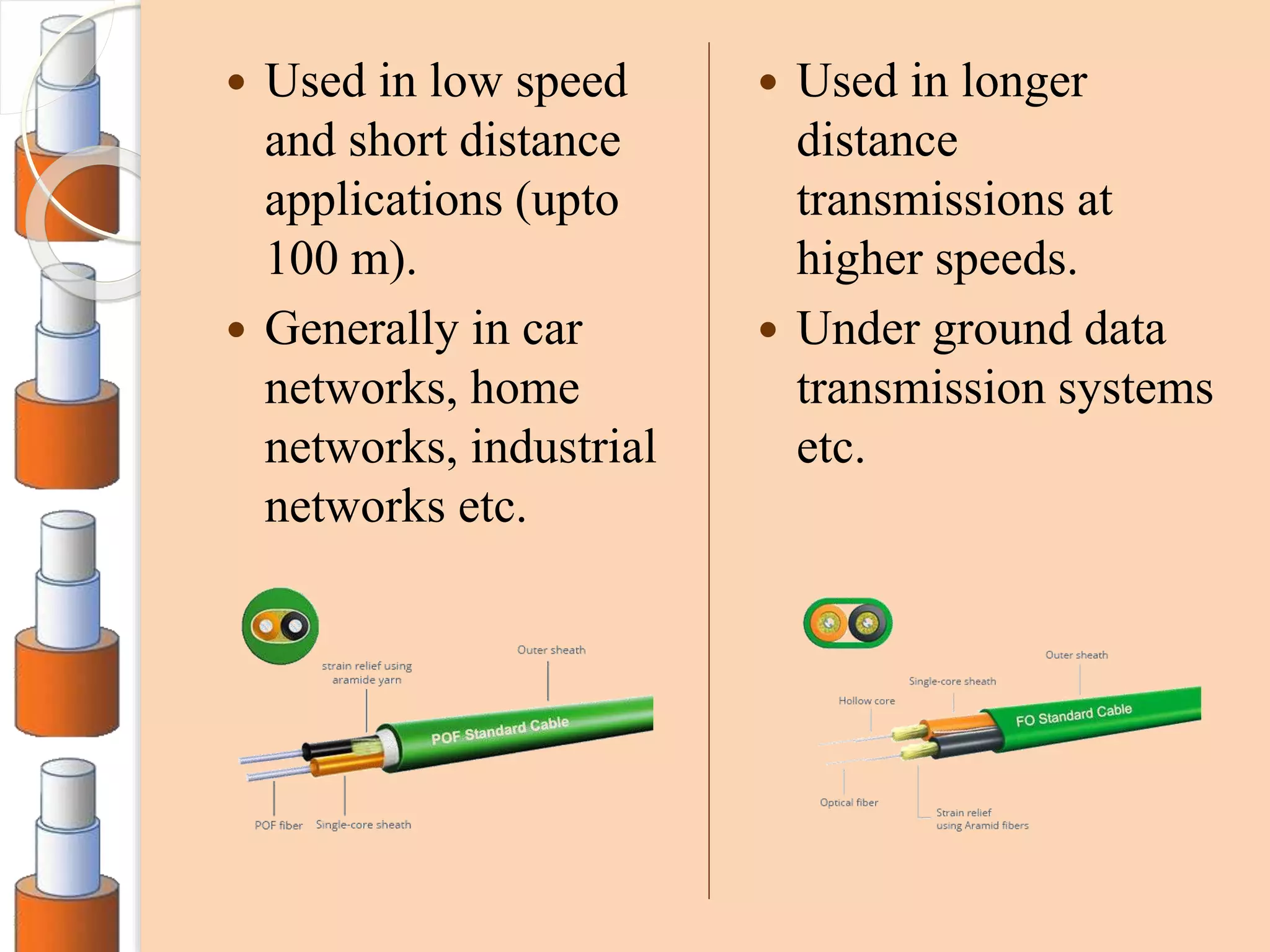

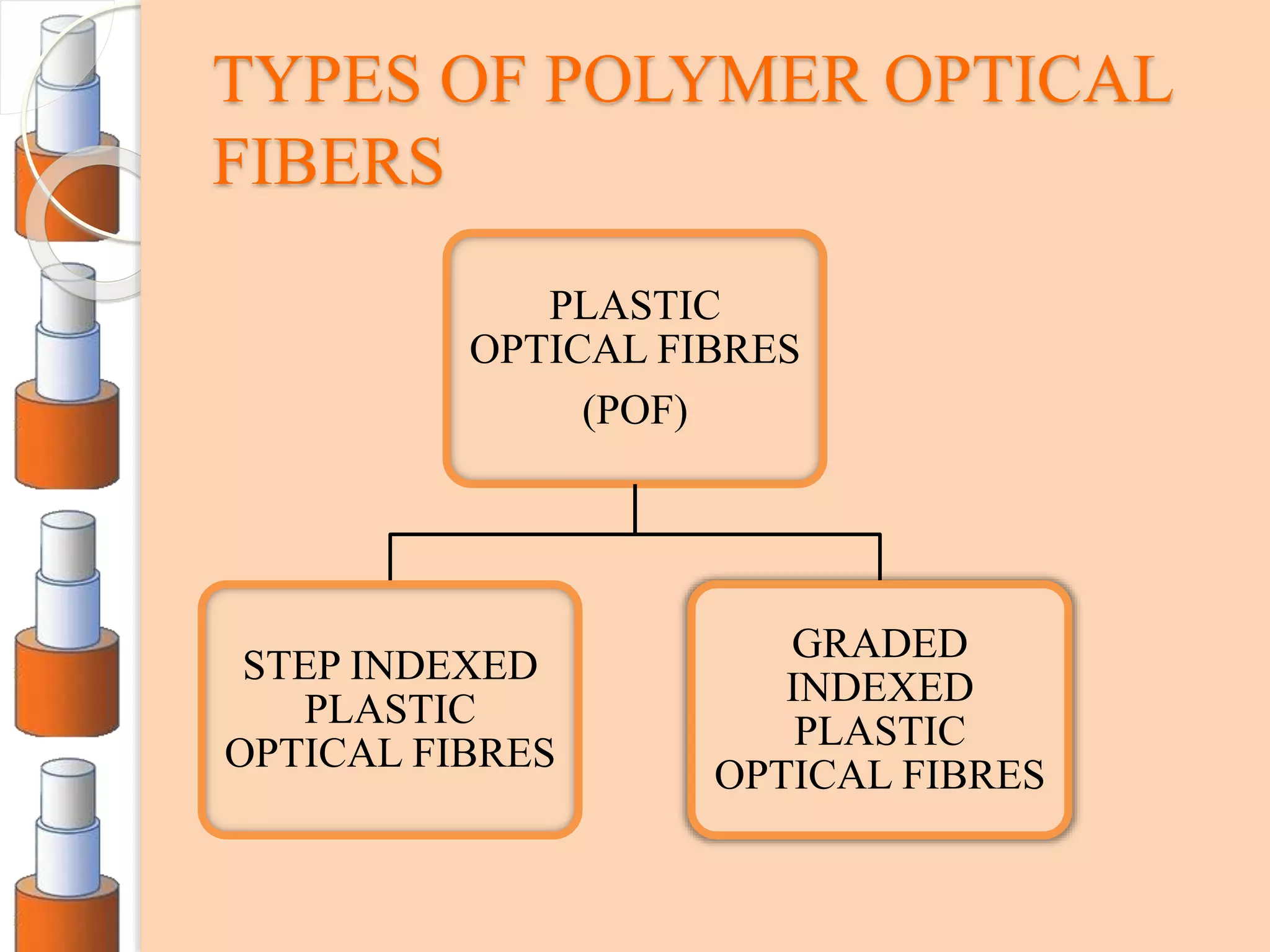

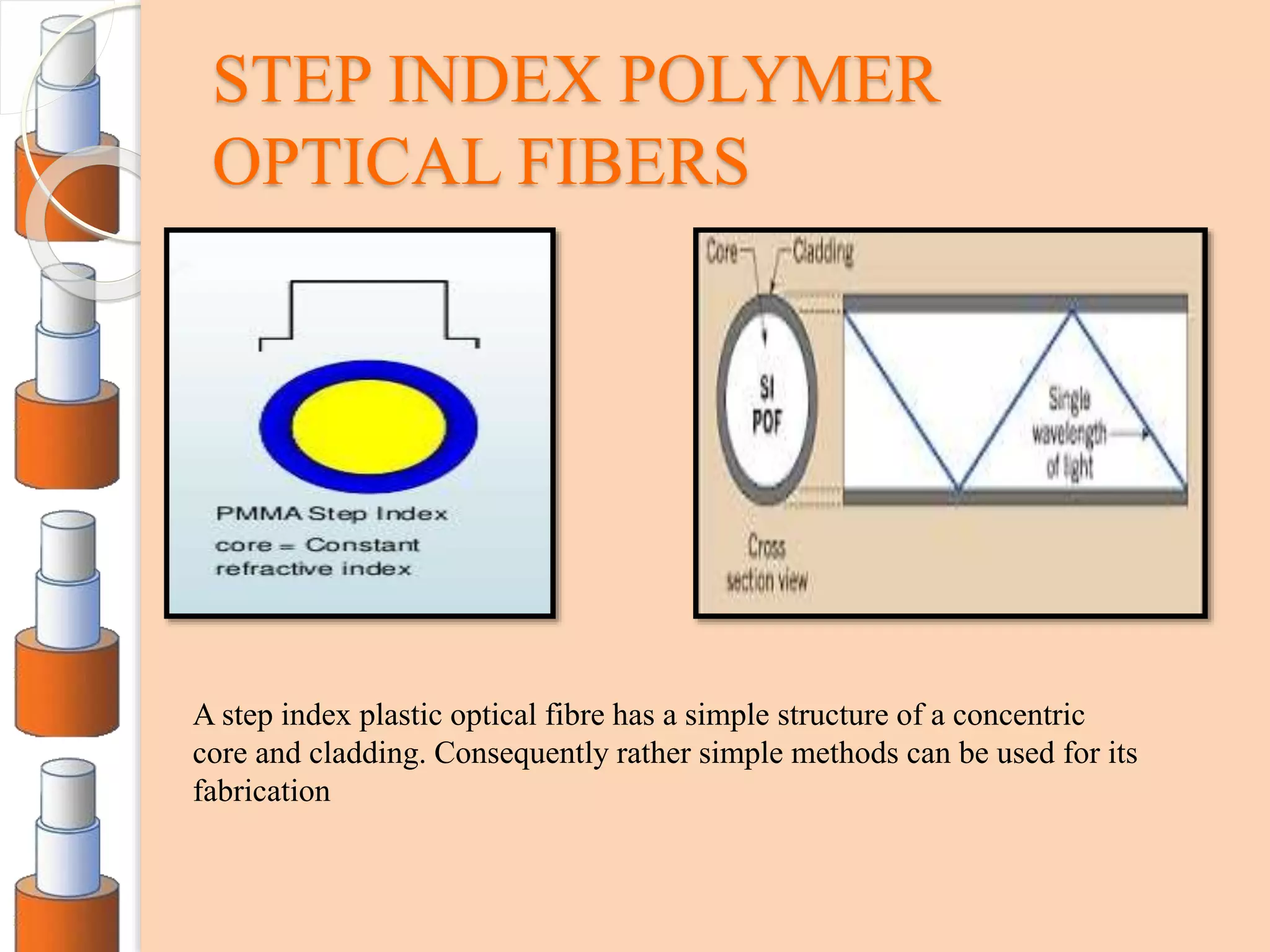

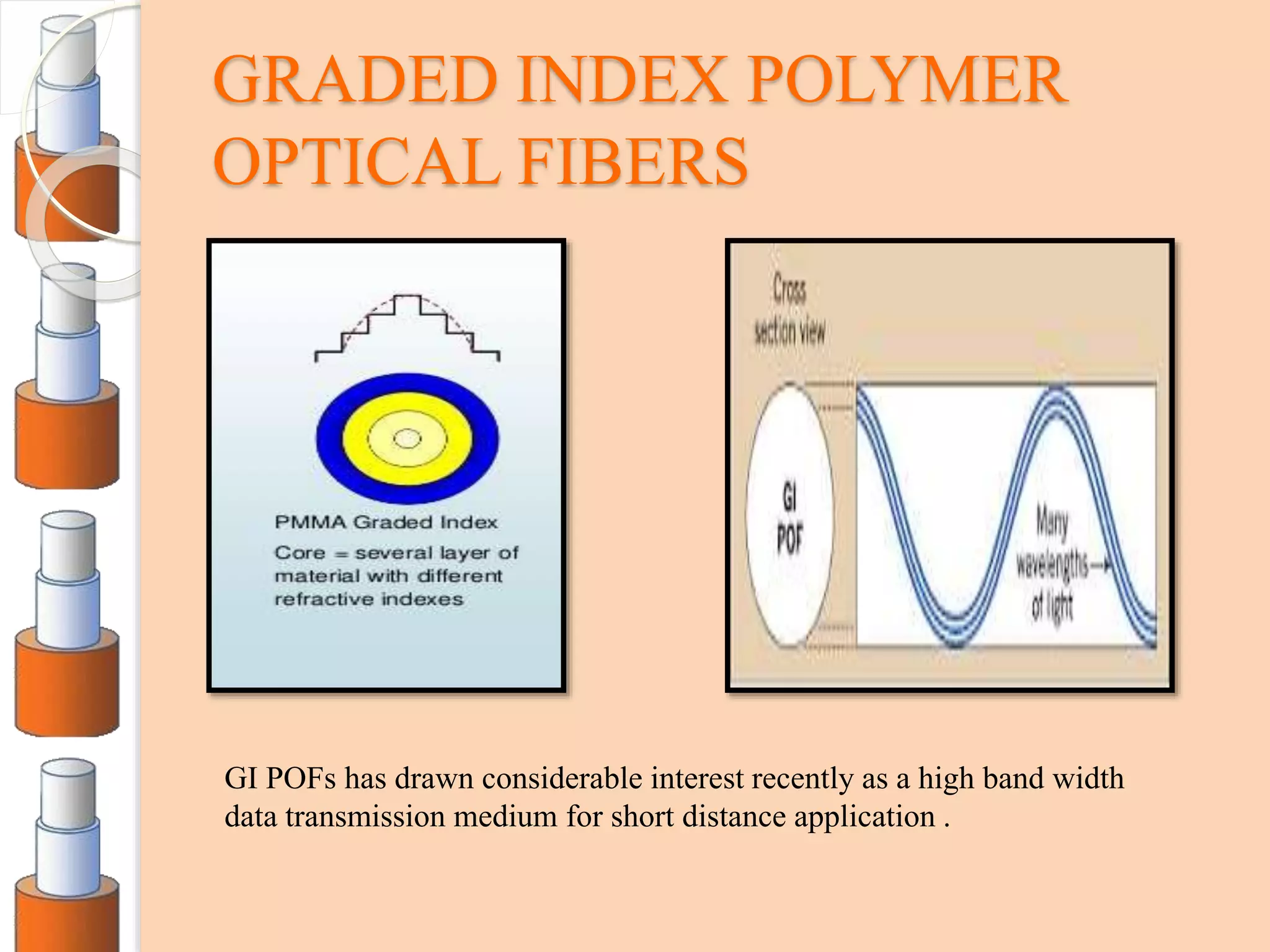

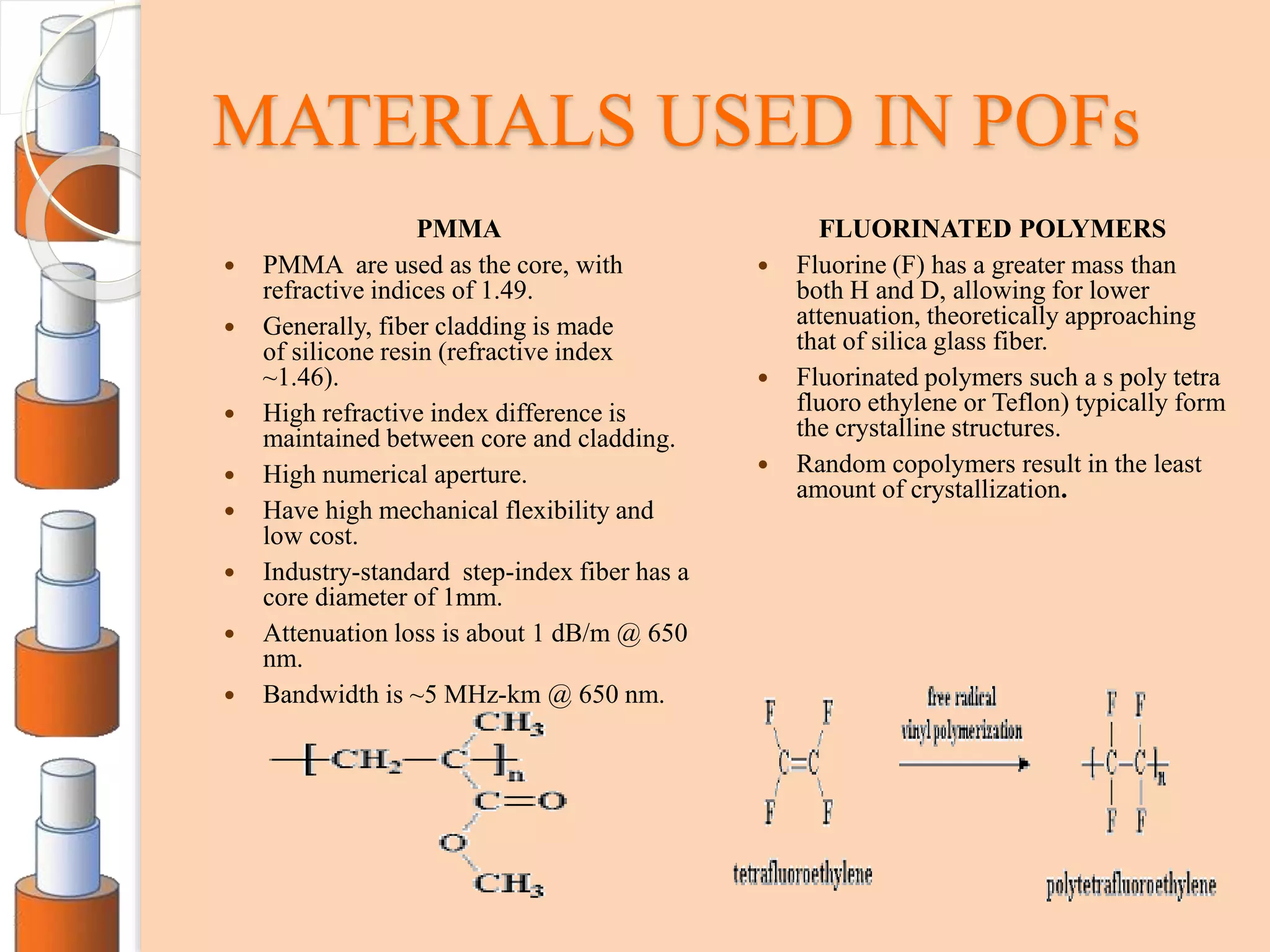

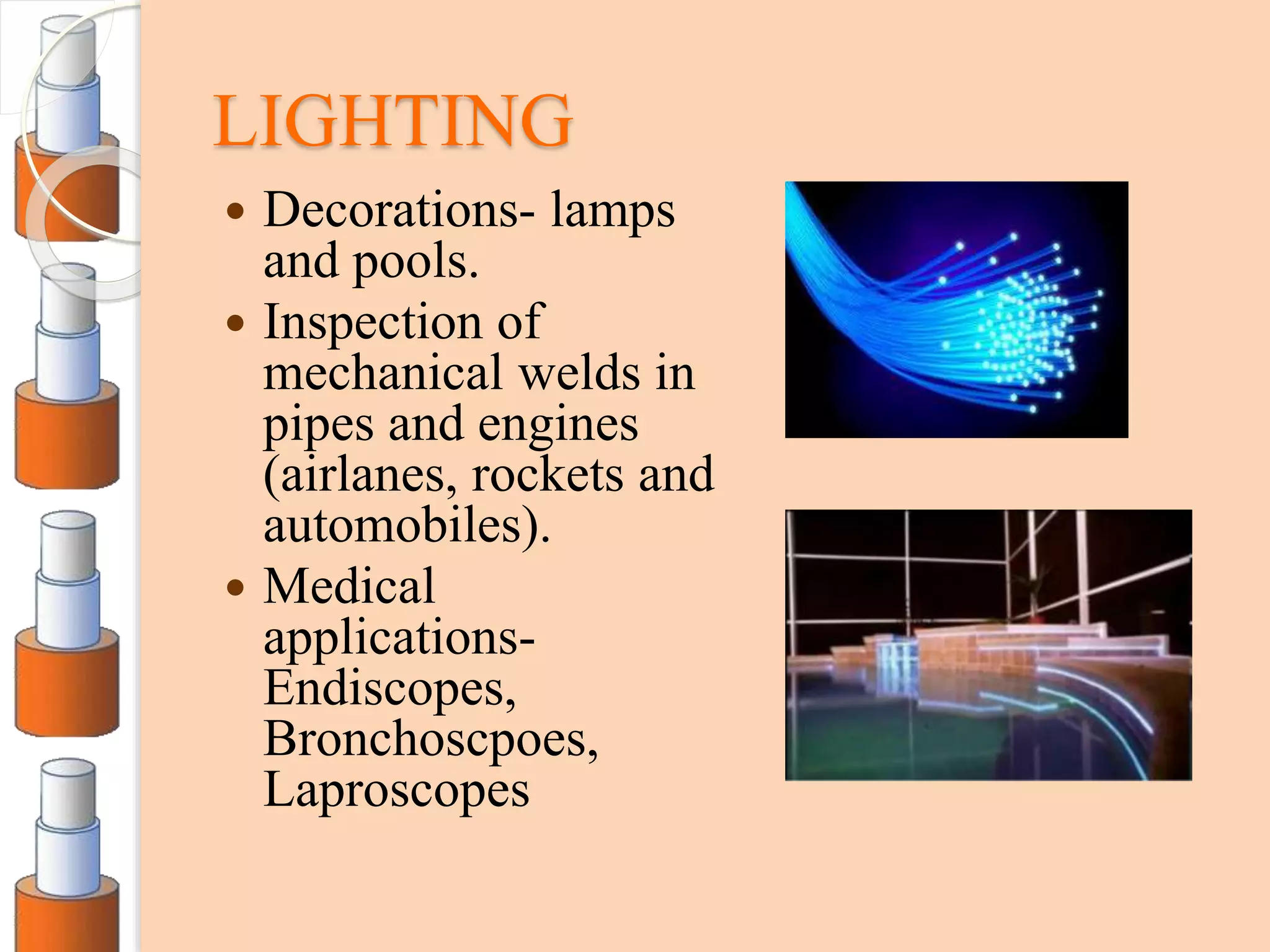

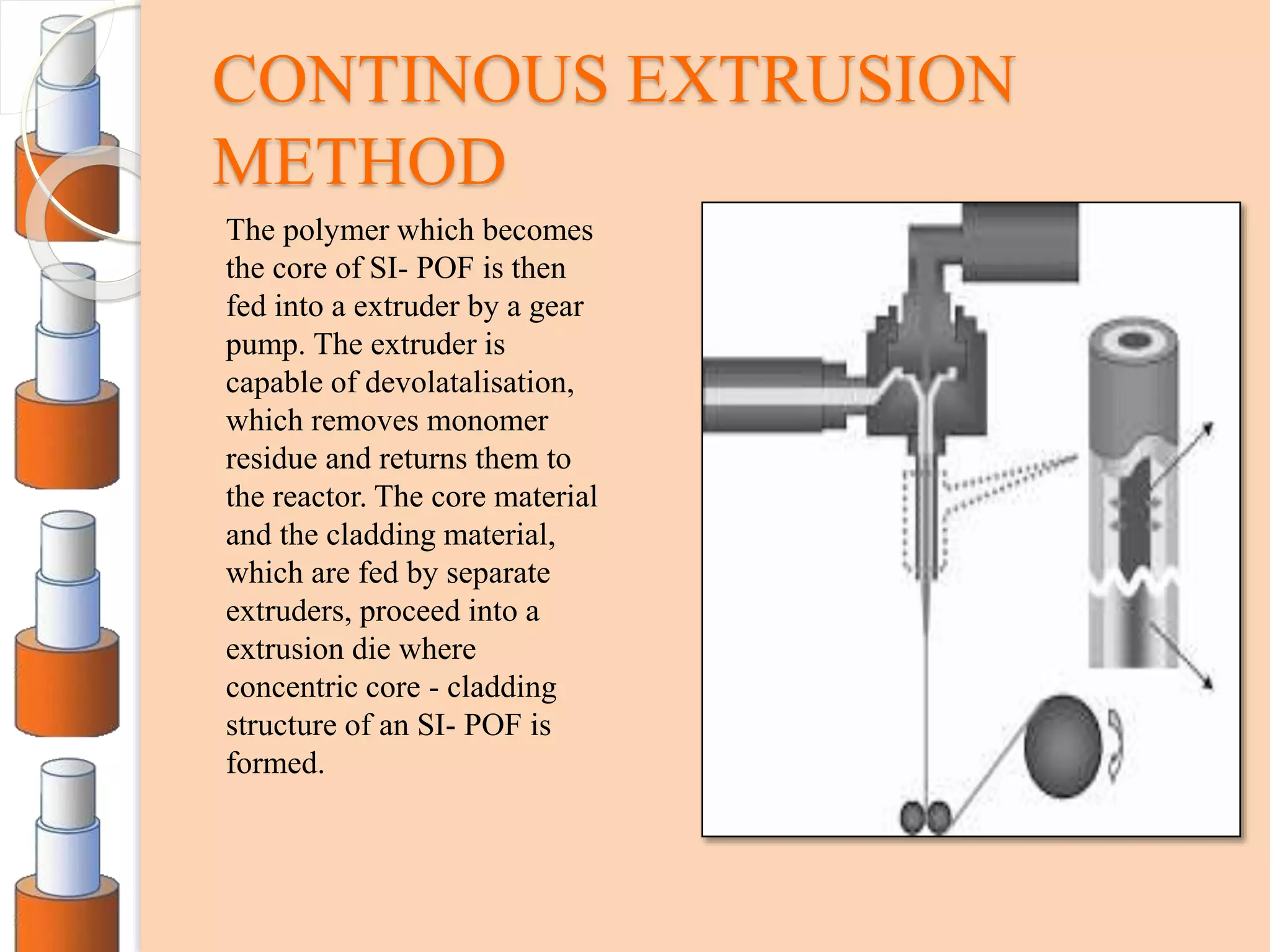

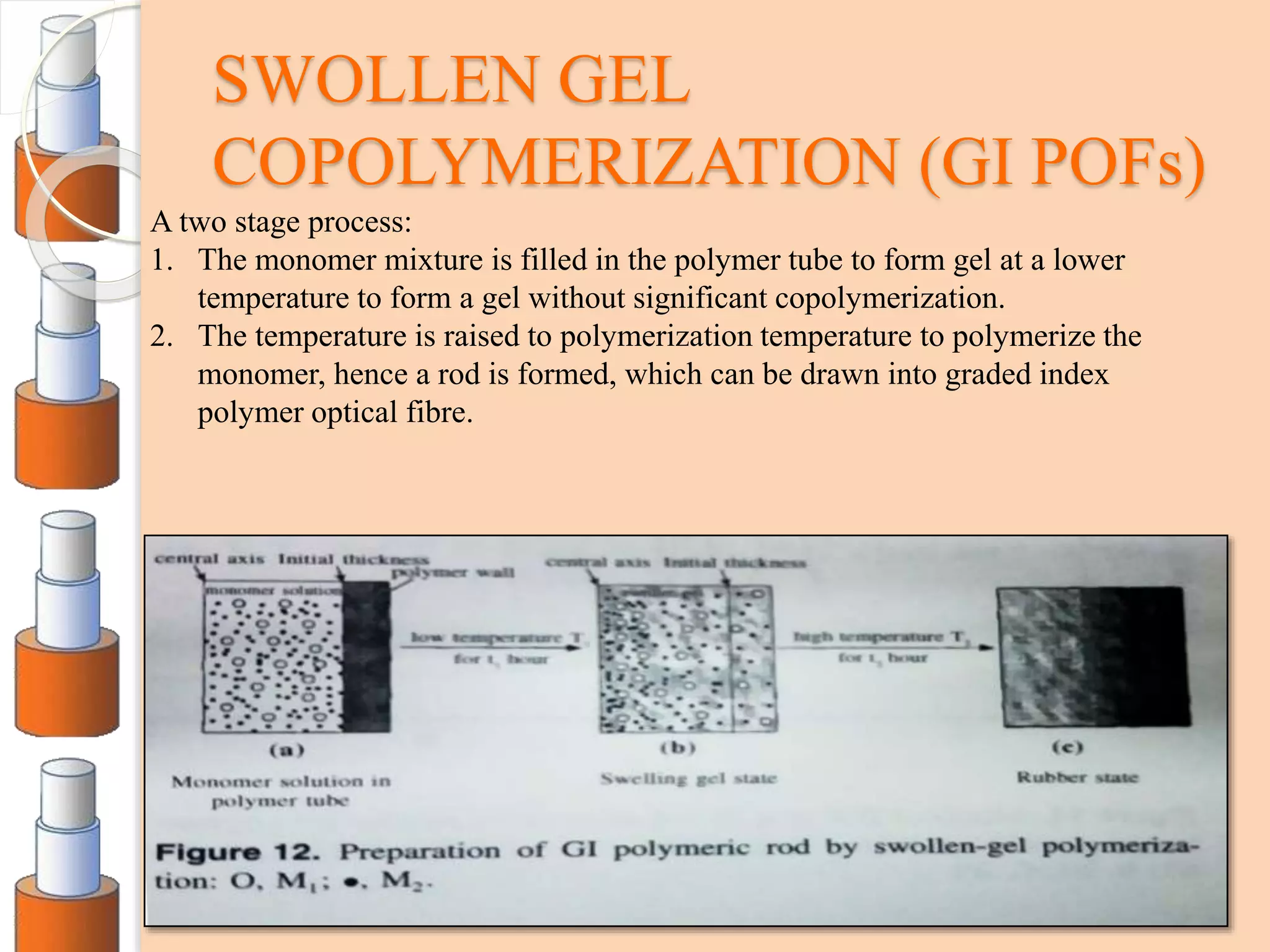

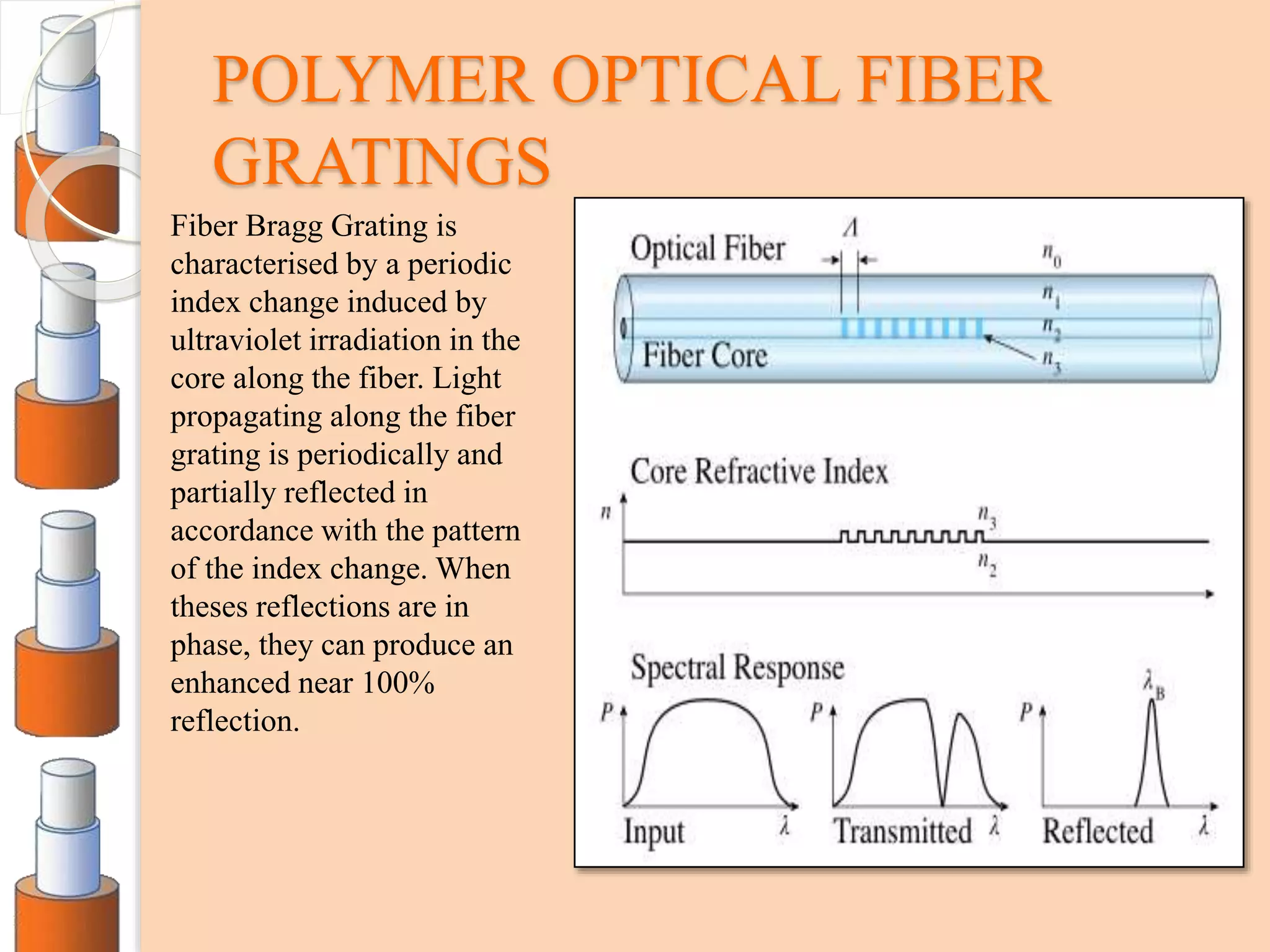

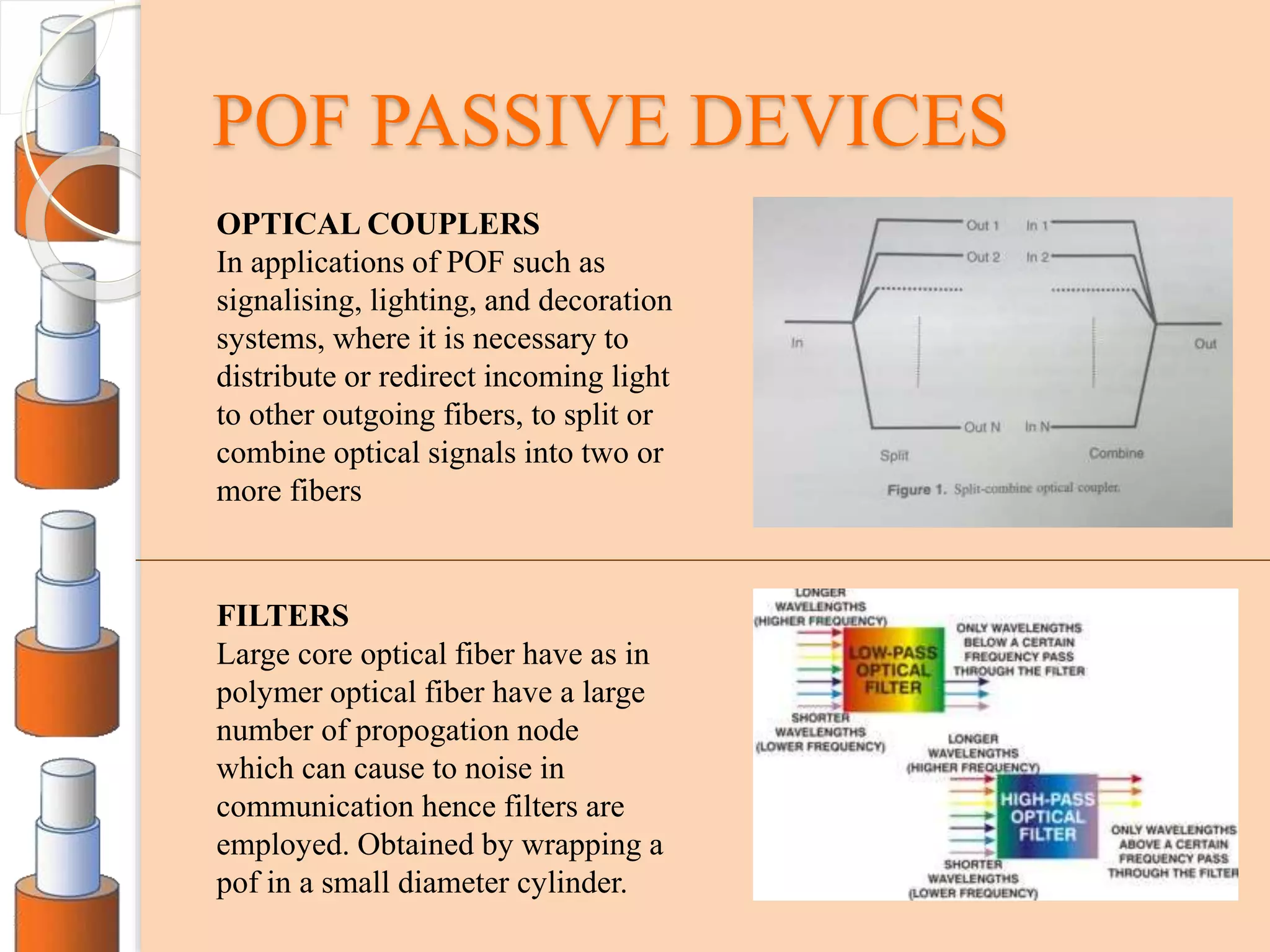

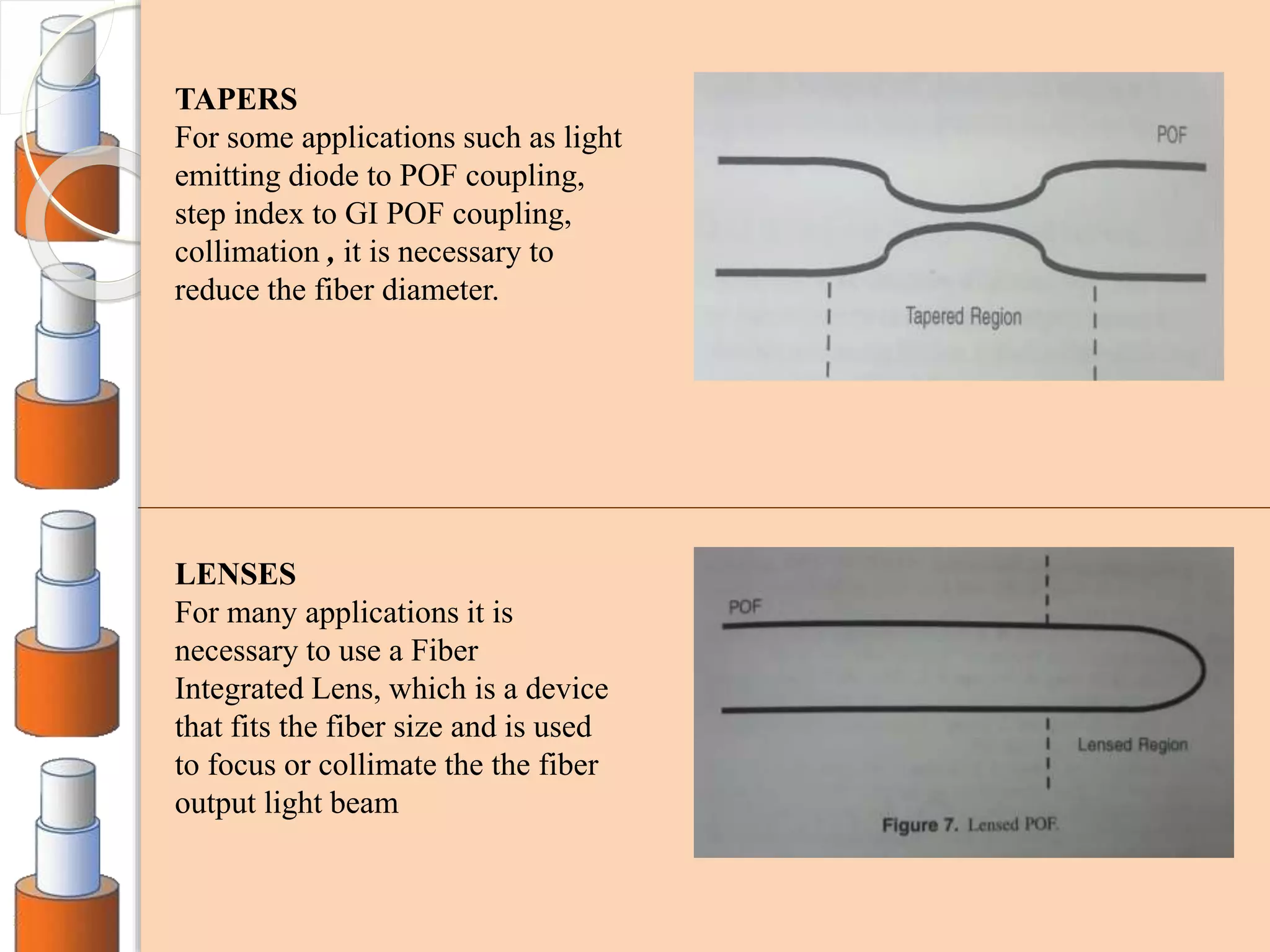

The document discusses polymer optical fibers (POFs), covering their introduction, history, comparison with glass optical fibers, classification, materials, applications, and fabrication methods. POFs are flexible and inexpensive, making them suitable for a variety of applications including lighting, communication, sensors, and automotive systems. It also addresses future prospects for POFs, suggesting their potential to replace copper cables in telecommunications.