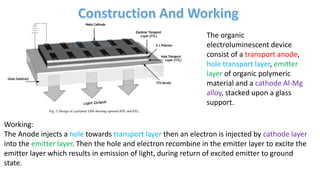

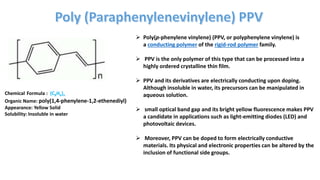

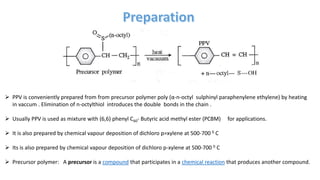

This document discusses electroluminescent polymers and poly(paraphenylene vinylene) (PPV). It lists the names and roll numbers of 5 students and defines electroluminescence. PPV is introduced as a conducting polymer that emits bright light when stimulated electronically. The document describes the structure of organic electroluminescent devices and explains how holes and electrons recombine in the emitter layer to produce light. PPV's chemical formula, properties, preparation methods, and applications in devices like LEDs and solar cells are summarized.