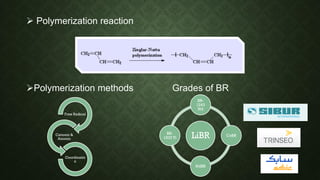

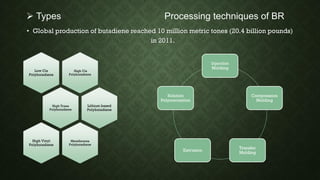

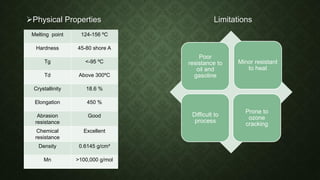

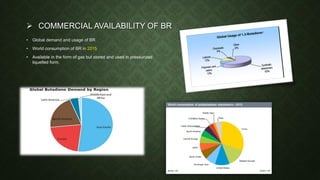

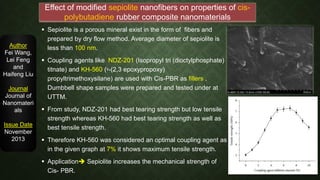

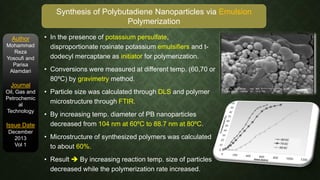

Polybutadiene is a synthetic rubber polymerized from the monomer 1,3-butadiene. It was first synthesized in 1910 and accounts for about a quarter of global synthetic rubber production, with around 70% used in tire manufacturing. Polybutadiene can be produced through various polymerization methods and processed through techniques like injection molding. It has good abrasion resistance and flexibility but poor resistance to oil and gasoline. Research articles discussed using sepiolite nanofibers to improve the mechanical properties of polybutadiene rubber composites and emulsion polymerization methods to synthesize polybutadiene nanoparticles. In conclusion, polybutadiene will continue to be widely used in tires and other applications due to its