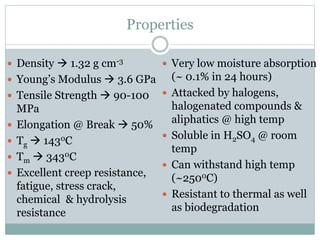

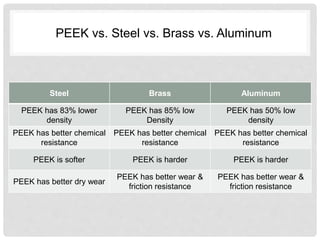

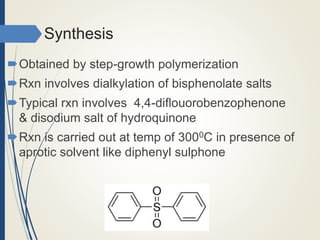

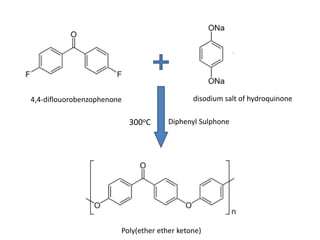

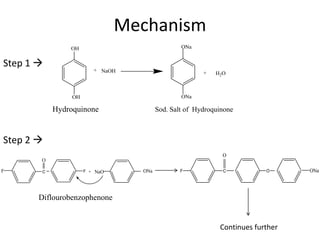

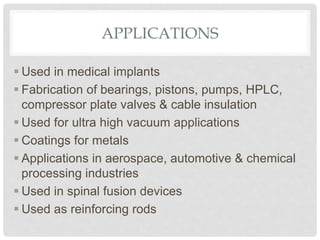

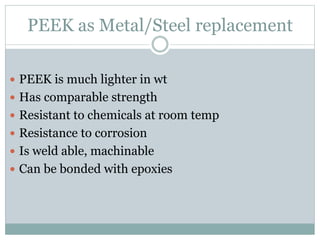

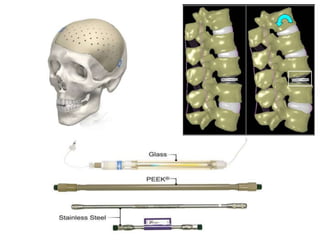

PEEK is a colorless, semi-crystalline thermoplastic with excellent mechanical properties that is formed through step-growth polymerization. It has a density of 1.32 g/cm3, glass transition temperature of 143°C, and melting temperature of 343°C. PEEK has high strength, creep resistance, and chemical resistance, making it suitable for applications in industries like aerospace, automotive, and medical implants where it can replace metals like steel. PEEK is synthesized through a step-growth reaction between 4,4-difluorobenzophenone and disodium salt of hydroquinone at 300°C in diphenyl sulfone.