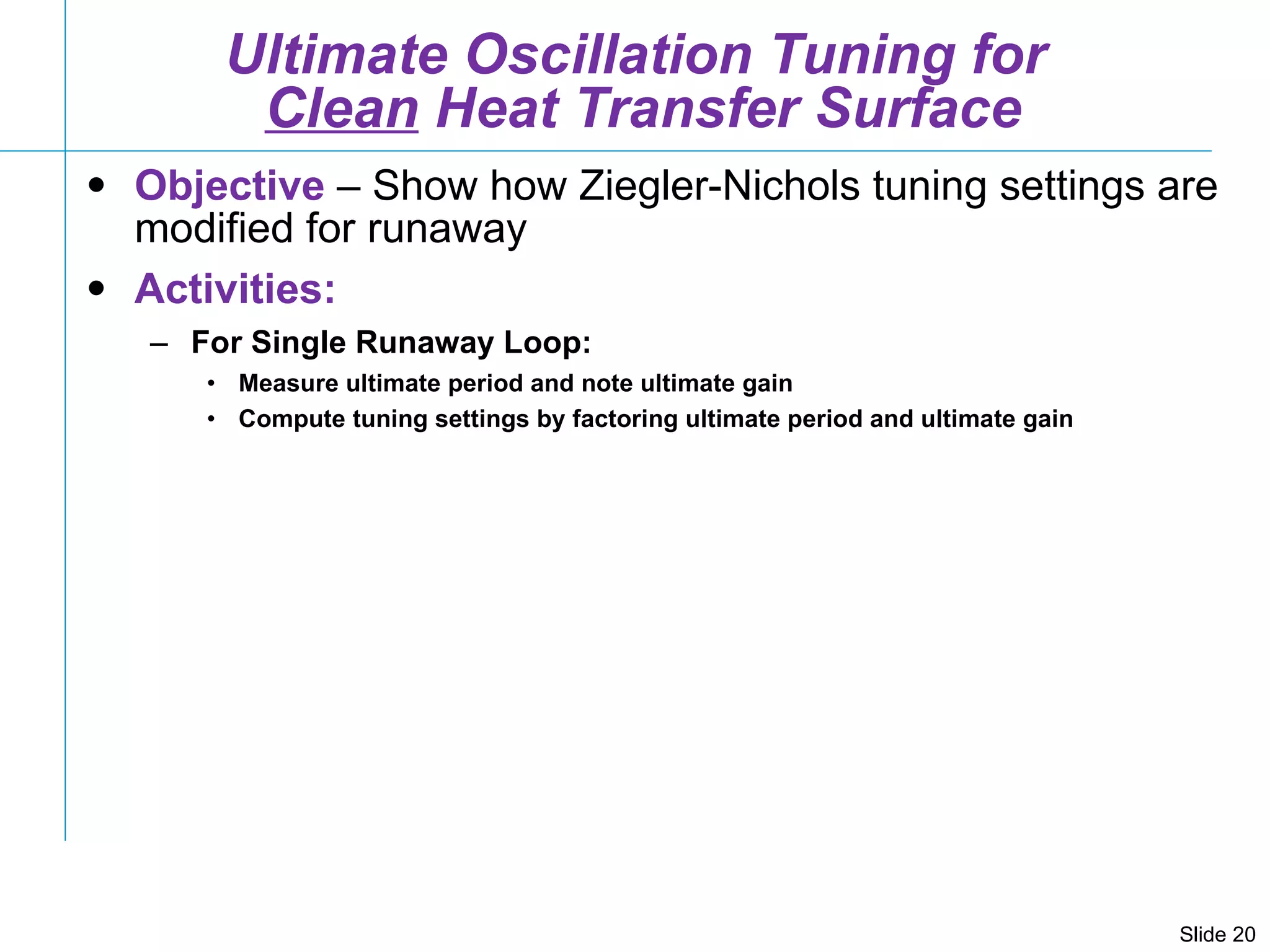

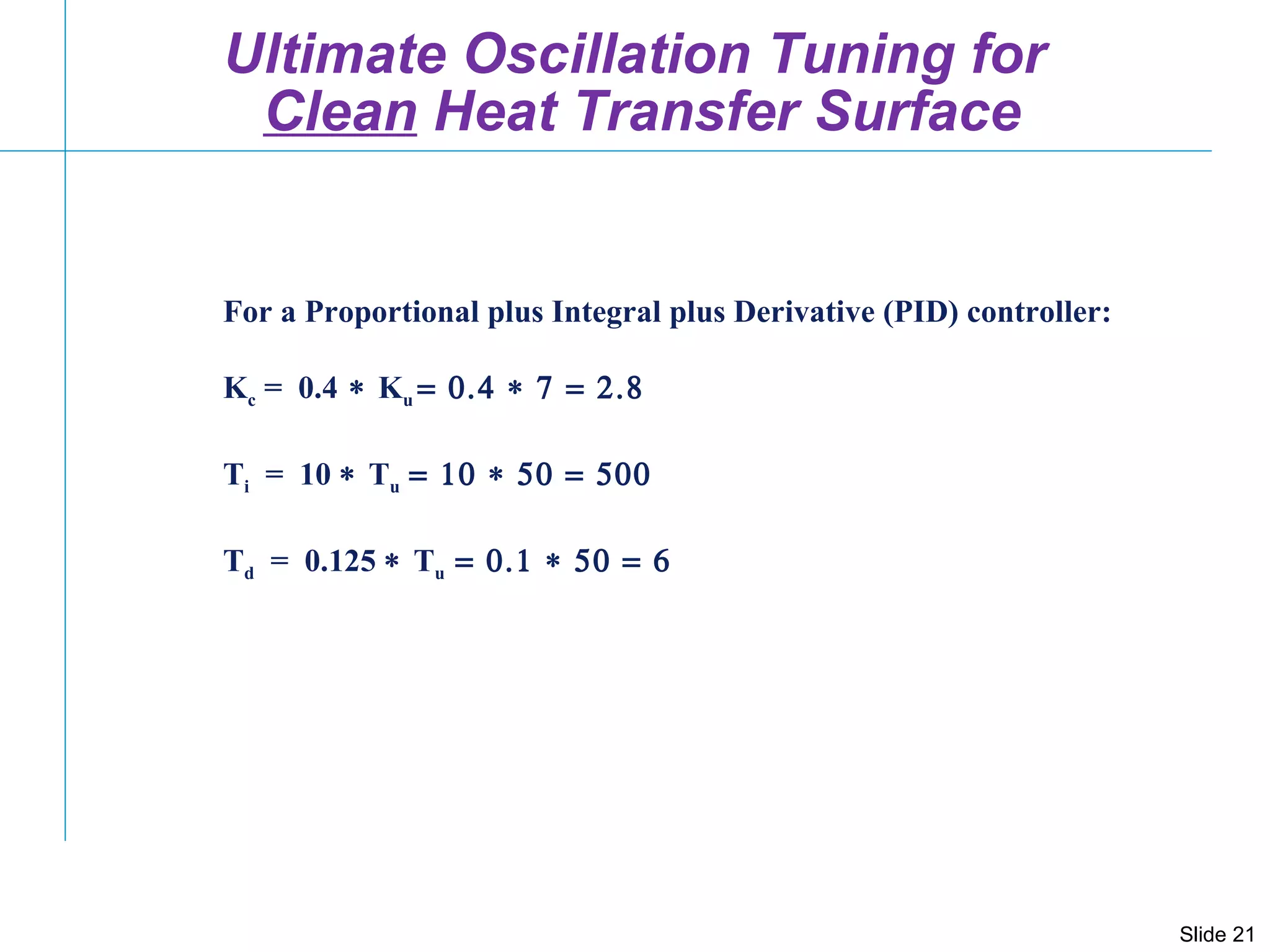

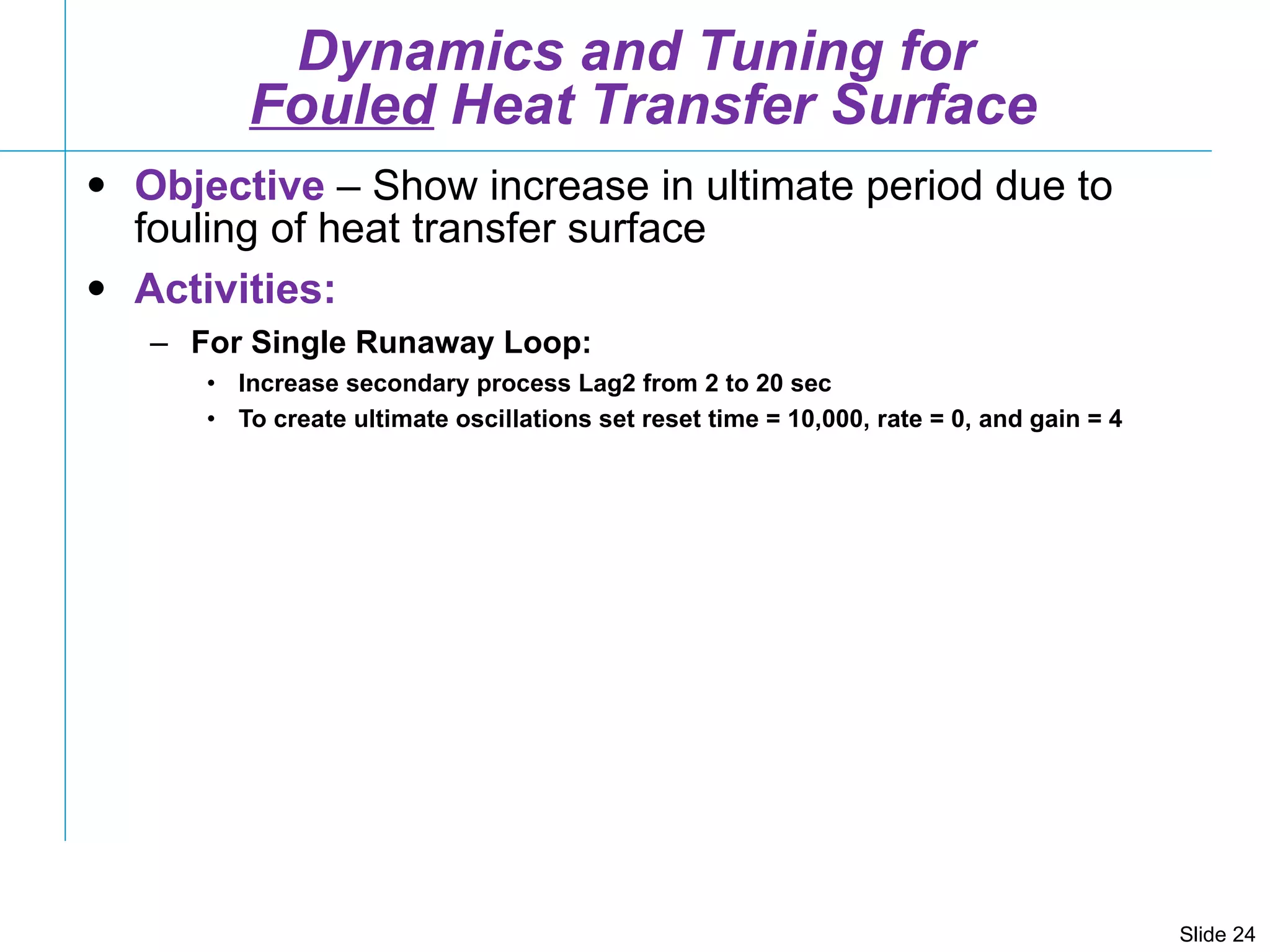

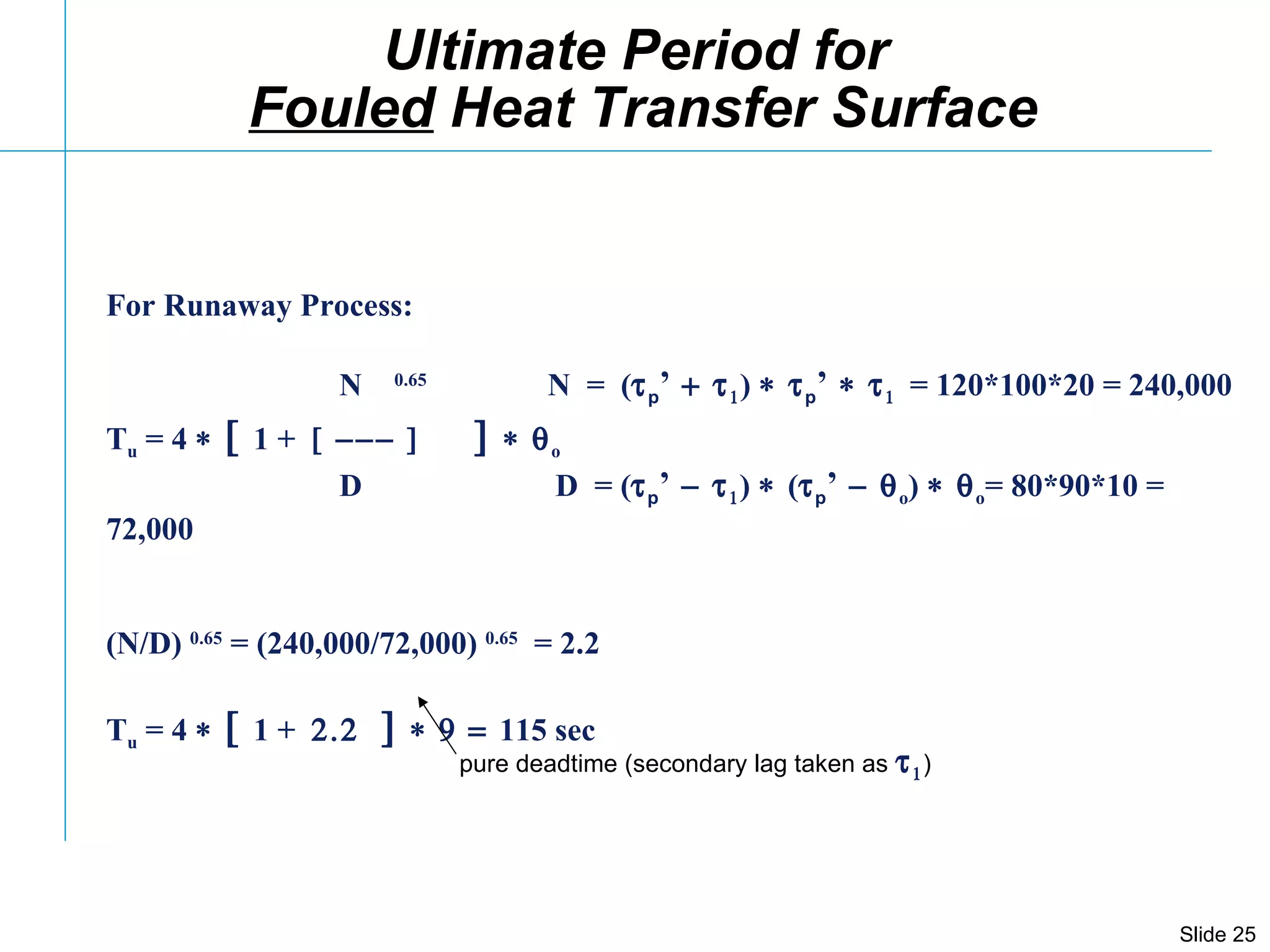

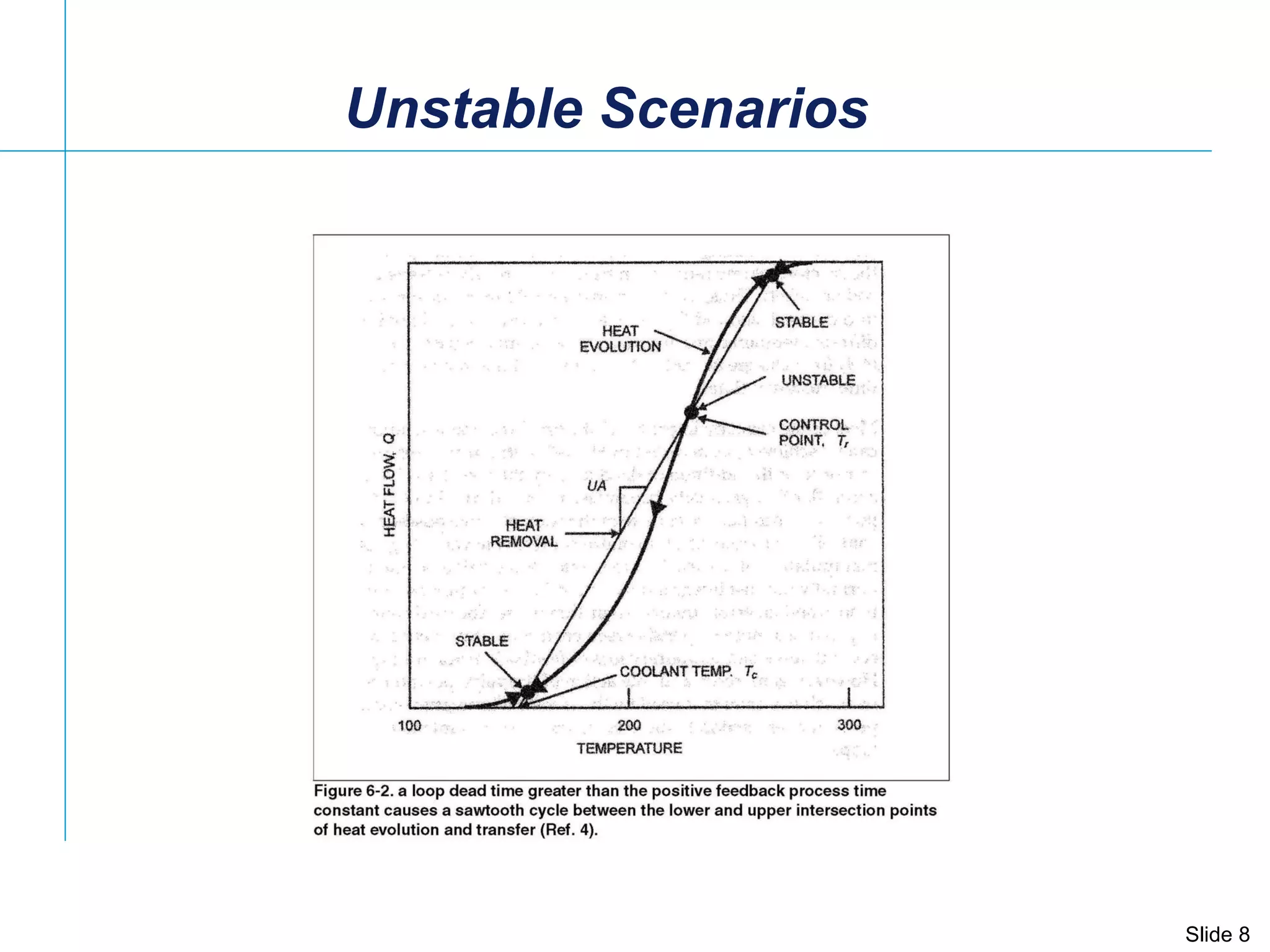

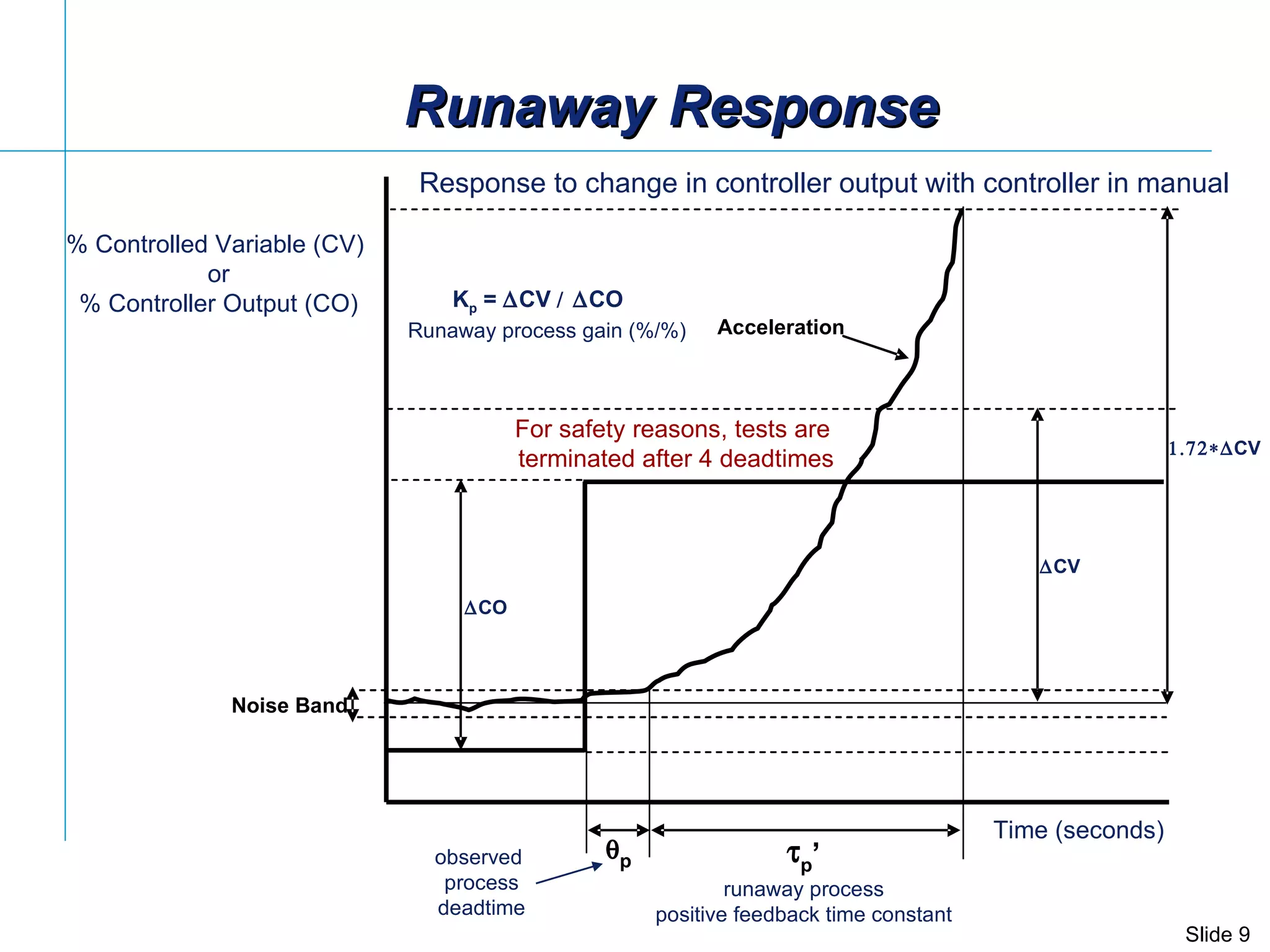

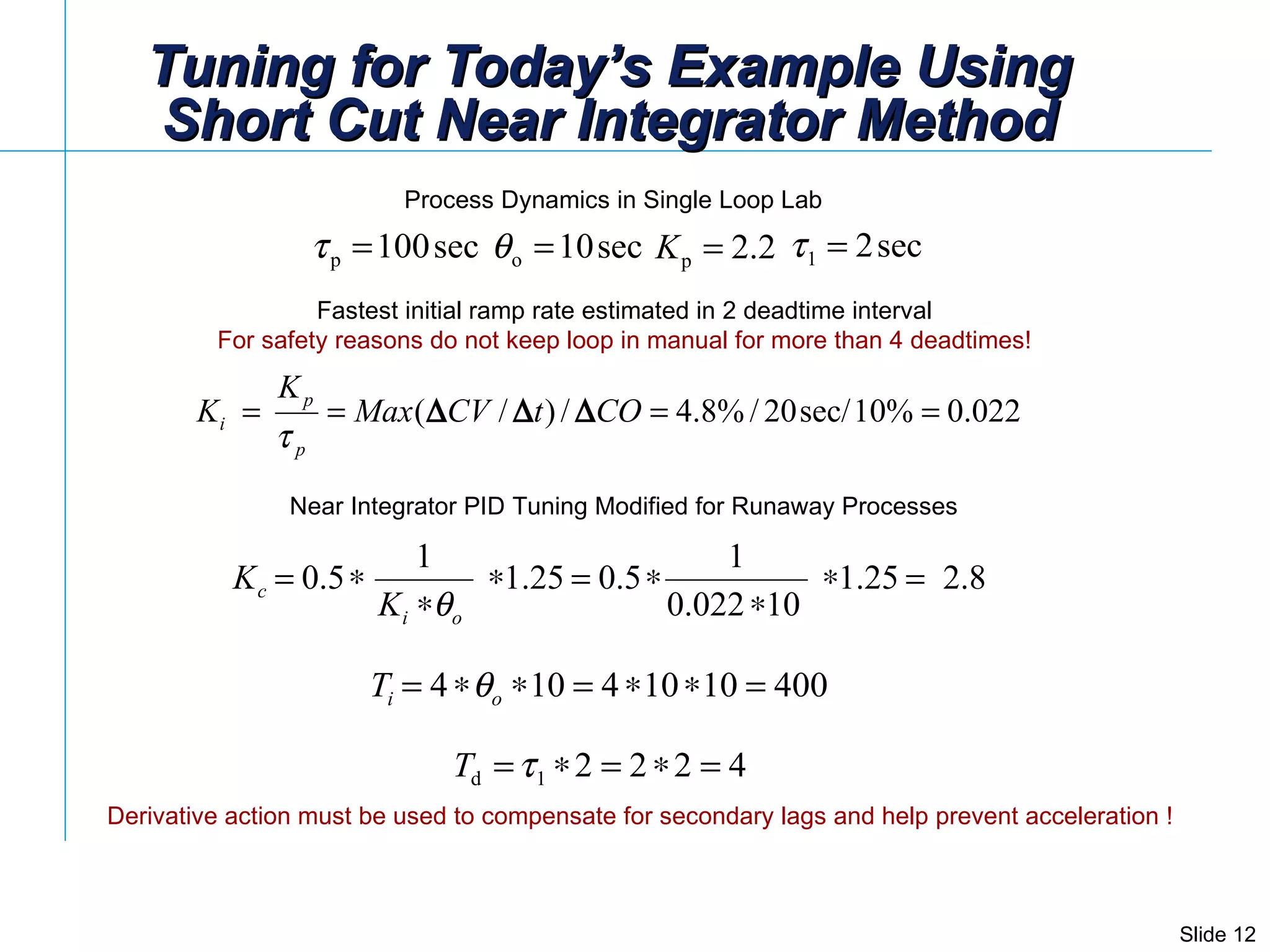

The document outlines a seminar series on PID control of runaway processes, emphasizing the importance of precise temperature control to prevent safety hazards and production issues in various chemical processes. It discusses the tuning of controllers for exothermic reactors, biological reactors, and acid-base systems, highlighting modifications needed for effective management of runaway responses. The document also includes examples of unwanted KPIs to avoid in control room reporting and outlines methods for tuning PID controllers in complex dynamic environments.

![Basis of First Order Approximation = Tan -1 ( ) negative phase shift (as approaches infinity, approaches -90 o phase shift) t = (-360 T o time shift B 1 AR = ---- = ----------------------- amplitude ratio A [1 + ( ] 1/2 Amplitude ratios are multiplicative (AR = AR 1 AR 2 ) and phase shifts are additive ( ) asis of first order approx method where gains are multiplicative and dead times are additive](https://image.slidesharecdn.com/pid-control-of-runaway-processes-greg-mcmillan-deminar-100825083021-phpapp02/75/PID-Control-of-Runaway-Processes-Greg-McMillan-Deminar-15-2048.jpg)

![Runaway Ultimate Gain Calculation [1 + ( 1 u [1 + ( p ’ T u ] 1/2 K u = ------------------------------------------------------------------- K p For T u < < (loop dominated by a large time constant), the error is negligible for the following simplification: ( p ’ K u = ------------------------ K p T u 2](https://image.slidesharecdn.com/pid-control-of-runaway-processes-greg-mcmillan-deminar-100825083021-phpapp02/75/PID-Control-of-Runaway-Processes-Greg-McMillan-Deminar-17-2048.jpg)