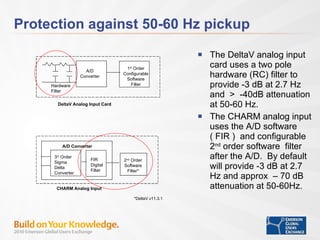

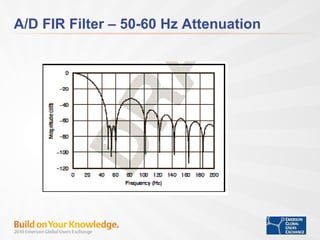

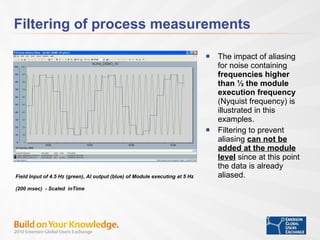

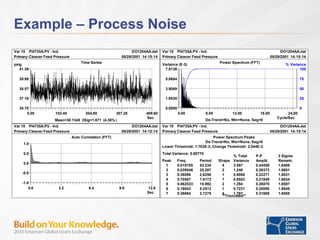

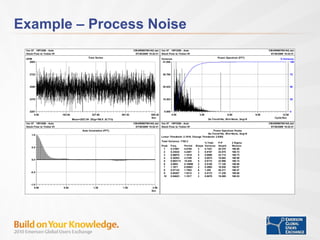

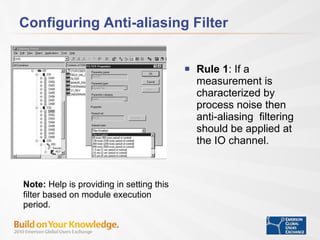

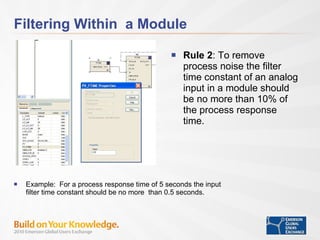

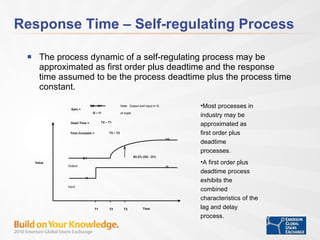

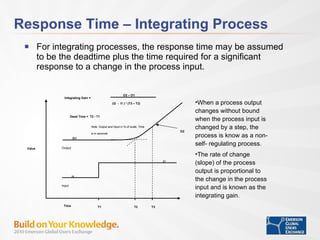

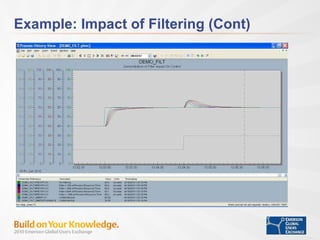

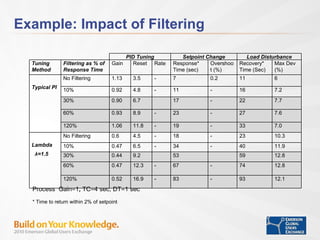

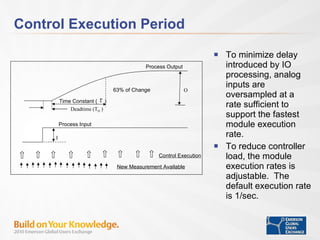

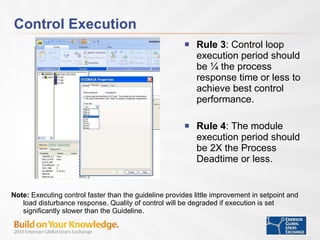

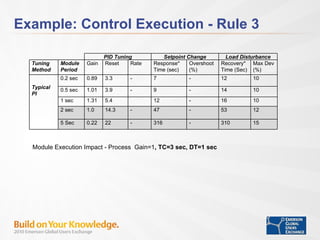

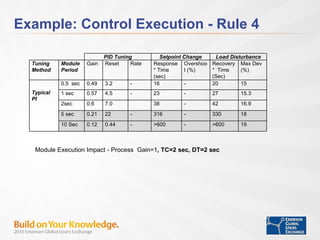

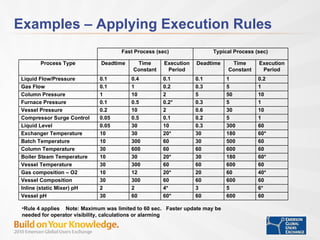

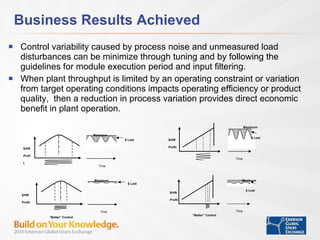

The document presents guidelines for configuring filtering and module execution periods to enhance control performance in DeltaV systems. It discusses the effects of aliasing and process noise, providing rules for setting filter time constants and execution periods based on process dynamics. Additionally, it highlights the economic benefits of reducing process variation through effective module execution and filtering strategies.