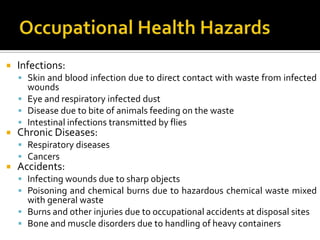

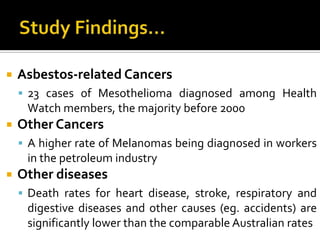

The document discusses occupational hazards in the oil and gas industry. It outlines several health risks workers may face, including infectious diseases, cancer due to chemical exposure like benzene, and accidents. It also summarizes findings from the Health Watch study in Australia which found cancer rates in petroleum workers were no higher than the general population and death rates from cancer and other diseases were lower. The document advocates for occupational risk management programs utilizing disciplines like ergonomics, health and safety to reduce injuries and increase productivity.