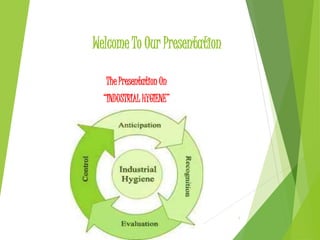

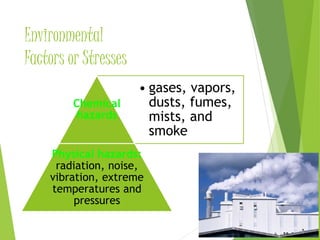

This presentation introduces industrial hygiene, which involves recognizing, evaluating, and controlling workplace hazards such as exposure to chemicals, noise, heat, and vibration. It was presented by three students and discusses the key aspects of industrial hygiene including the OSHAct of 1970, common environmental hazards, the OSHA hierarchy of controls, types of exposures and air contaminants, and the importance of protection and hygiene surveys. The benefits of industrial hygiene are highlighted as keeping known hazards under control, establishing standards, preventing accidents, and increasing worker morale and production while decreasing costs.