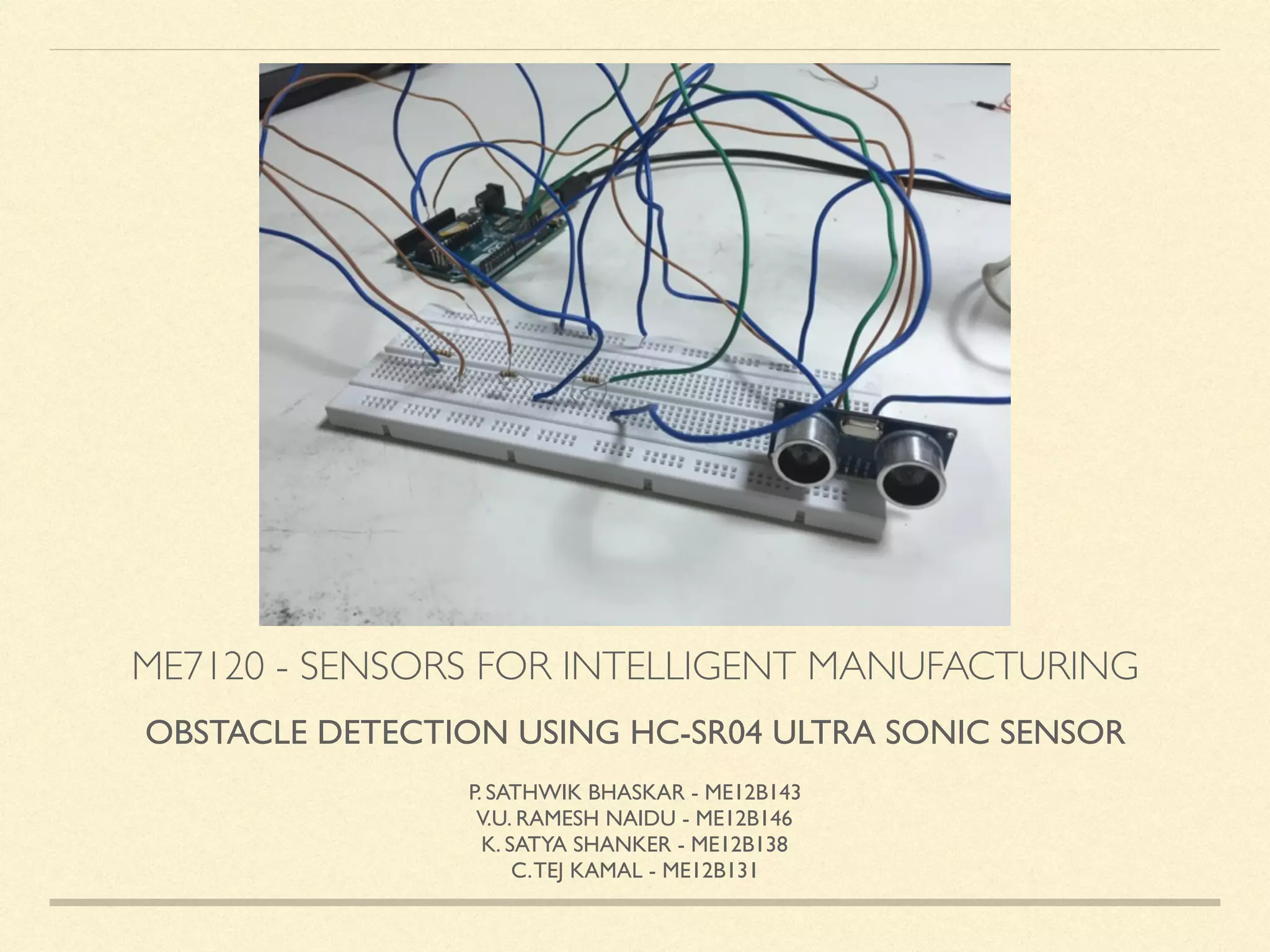

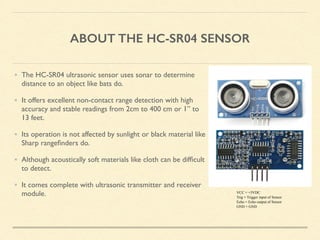

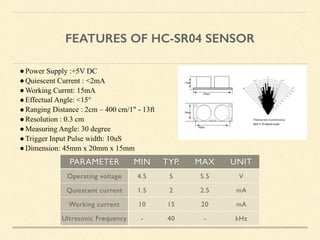

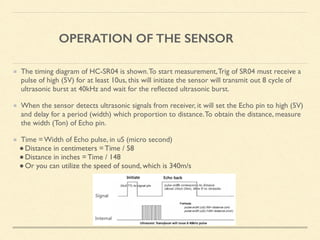

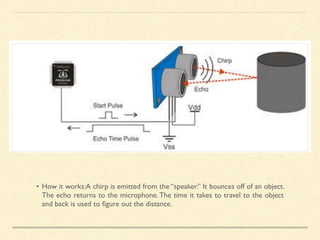

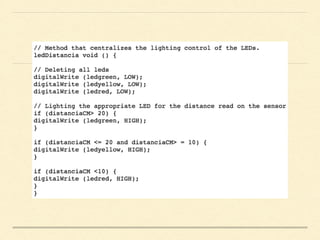

The document summarizes the working principles and applications of ultrasonic sensors, specifically the HC-SR04 sensor. It describes how ultrasonic sensors use piezoelectric materials to generate and detect sound waves to measure the distance to targets. The HC-SR04 sensor can detect objects from 2cm to 400cm away and is unaffected by light or dark surfaces. Its operation involves transmitting ultrasonic pulses and measuring the echo return time to determine distance. Common applications of ultrasonic sensors include obstacle detection, motion sensing, and liquid level measurement.