1) Ultrasonic sensors use sound waves instead of light for detection and measurement purposes. They are commonly used for distance measurement, detecting hidden objects, and water level detection.

2) Ultrasonic sensors work by transmitting ultrasonic waves and detecting echoes reflected back from objects. By measuring the time between the wave transmission and echo reception, the distance to the object can be determined.

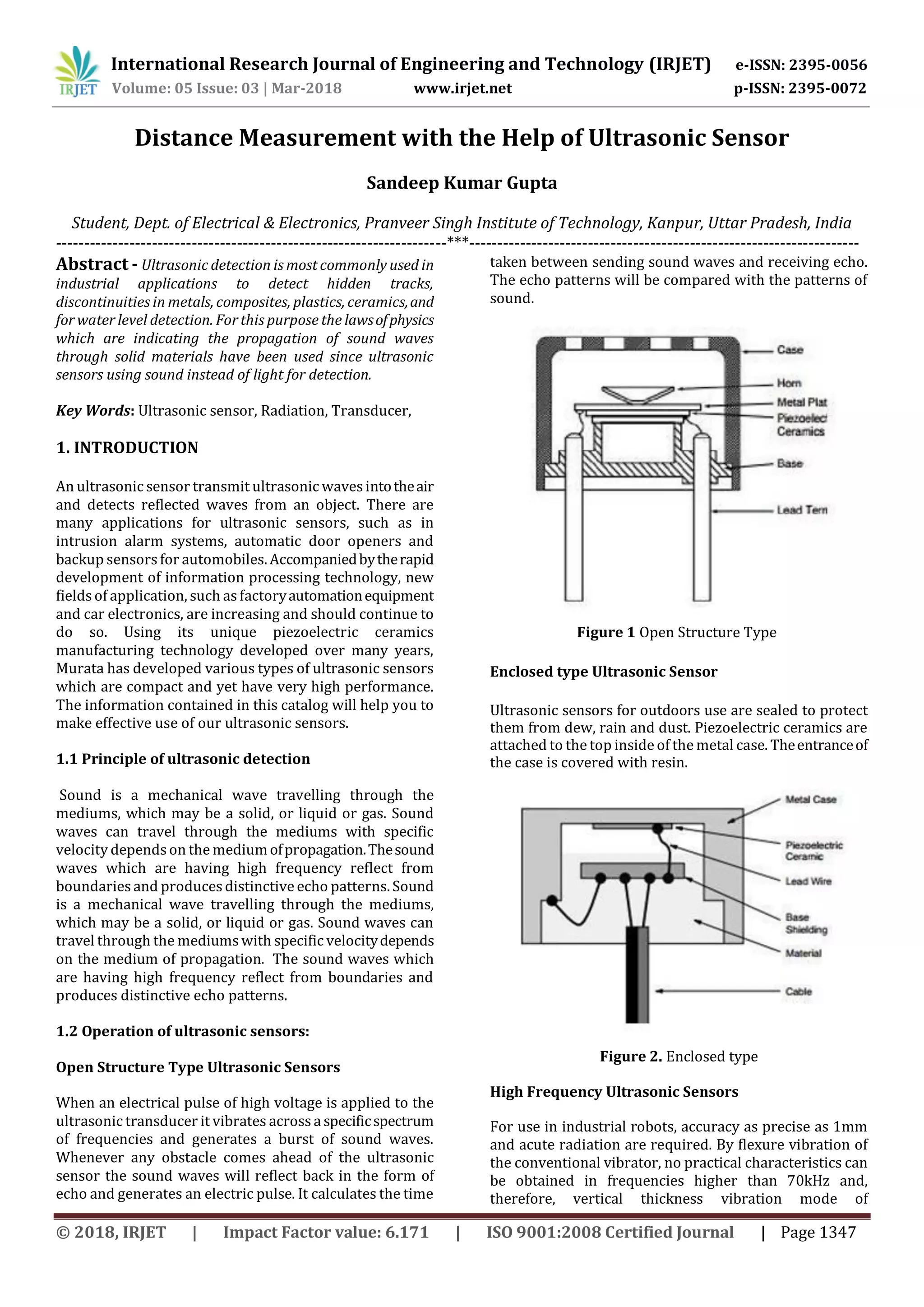

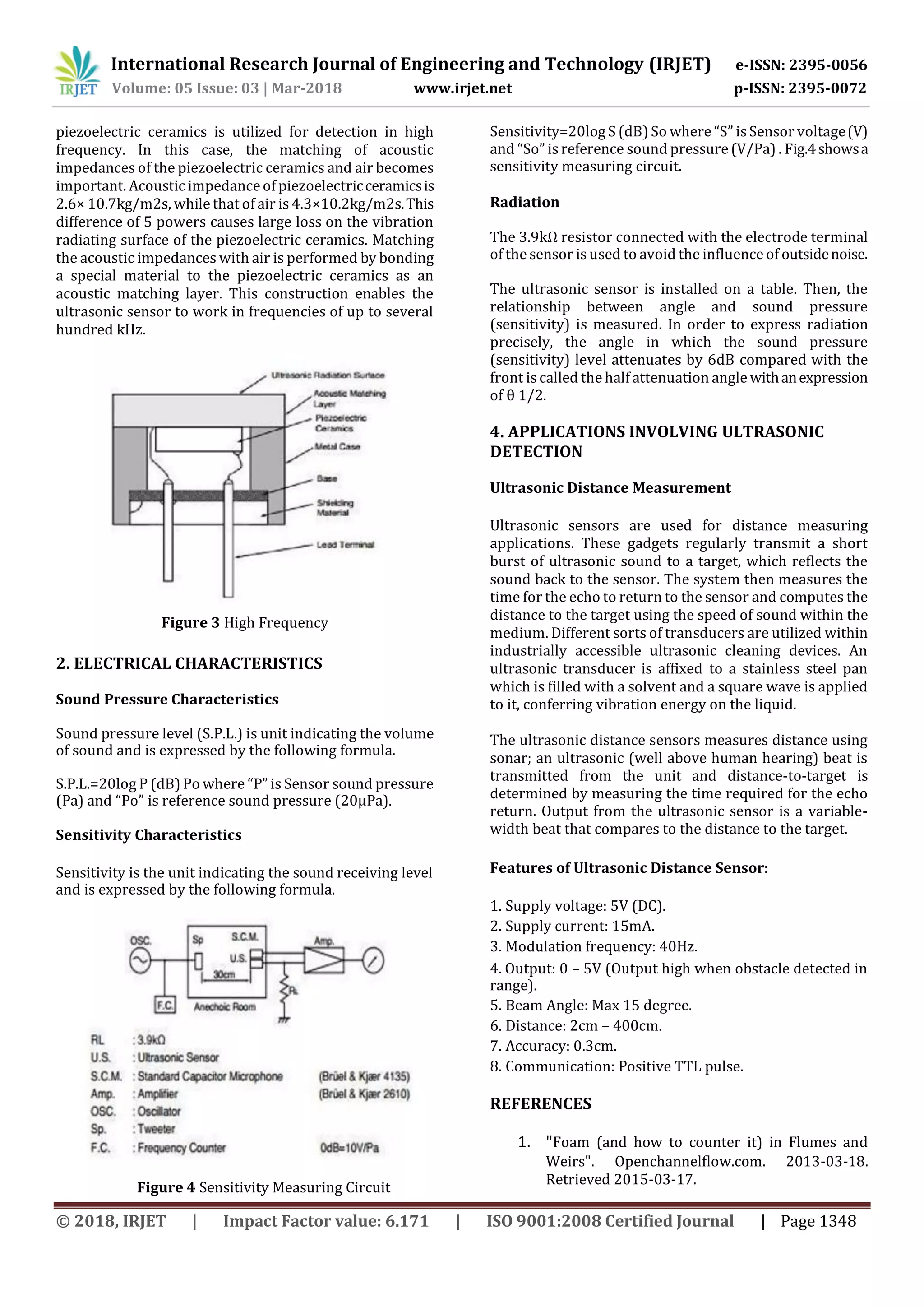

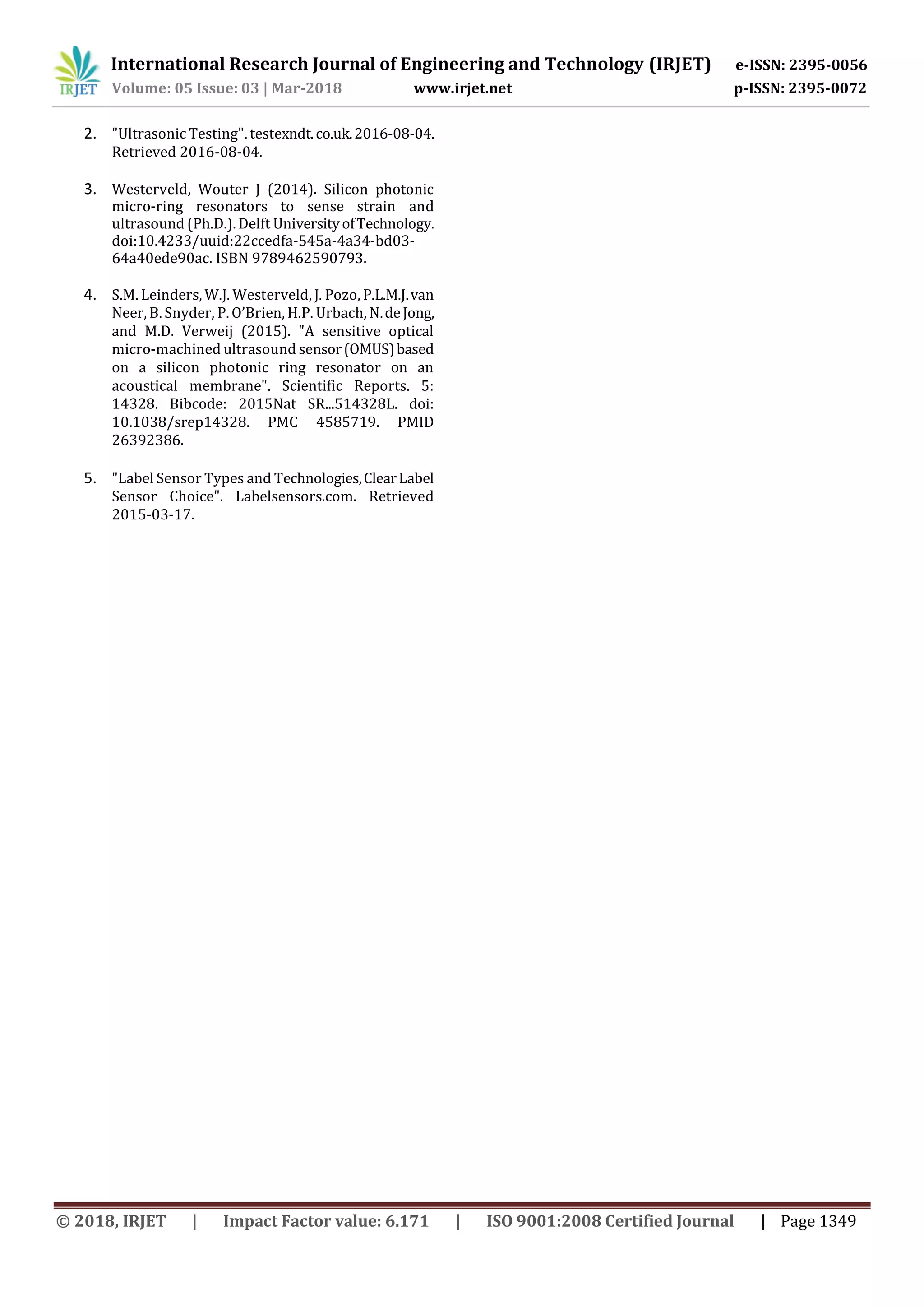

3) There are different types of ultrasonic sensors including open structure sensors, enclosed sensors protected from the environment, and high frequency sensors used for precise industrial applications. Ultrasonic sensors have various applications including intruder alarms, automatic doors, and backup sensors in vehicles.