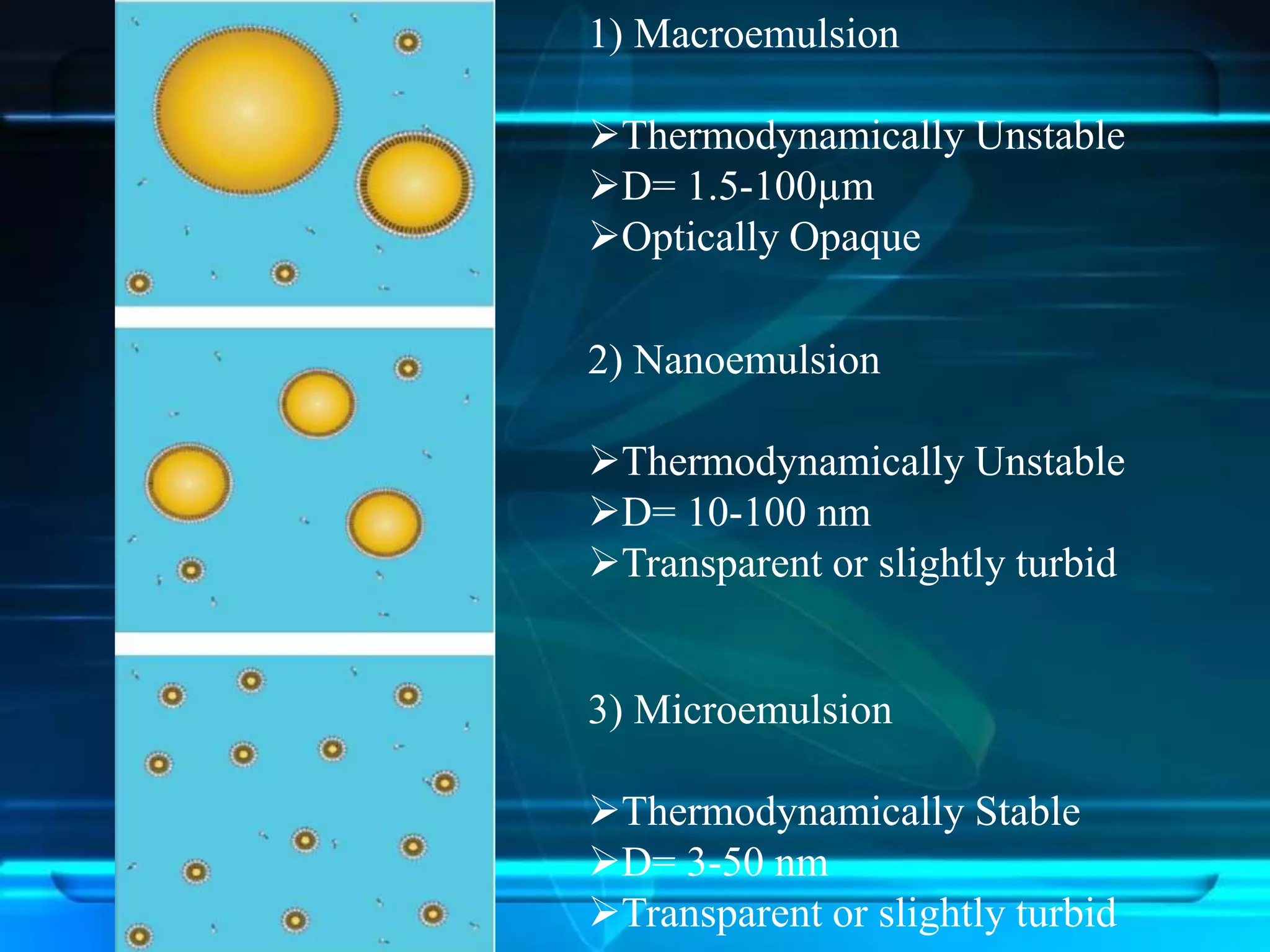

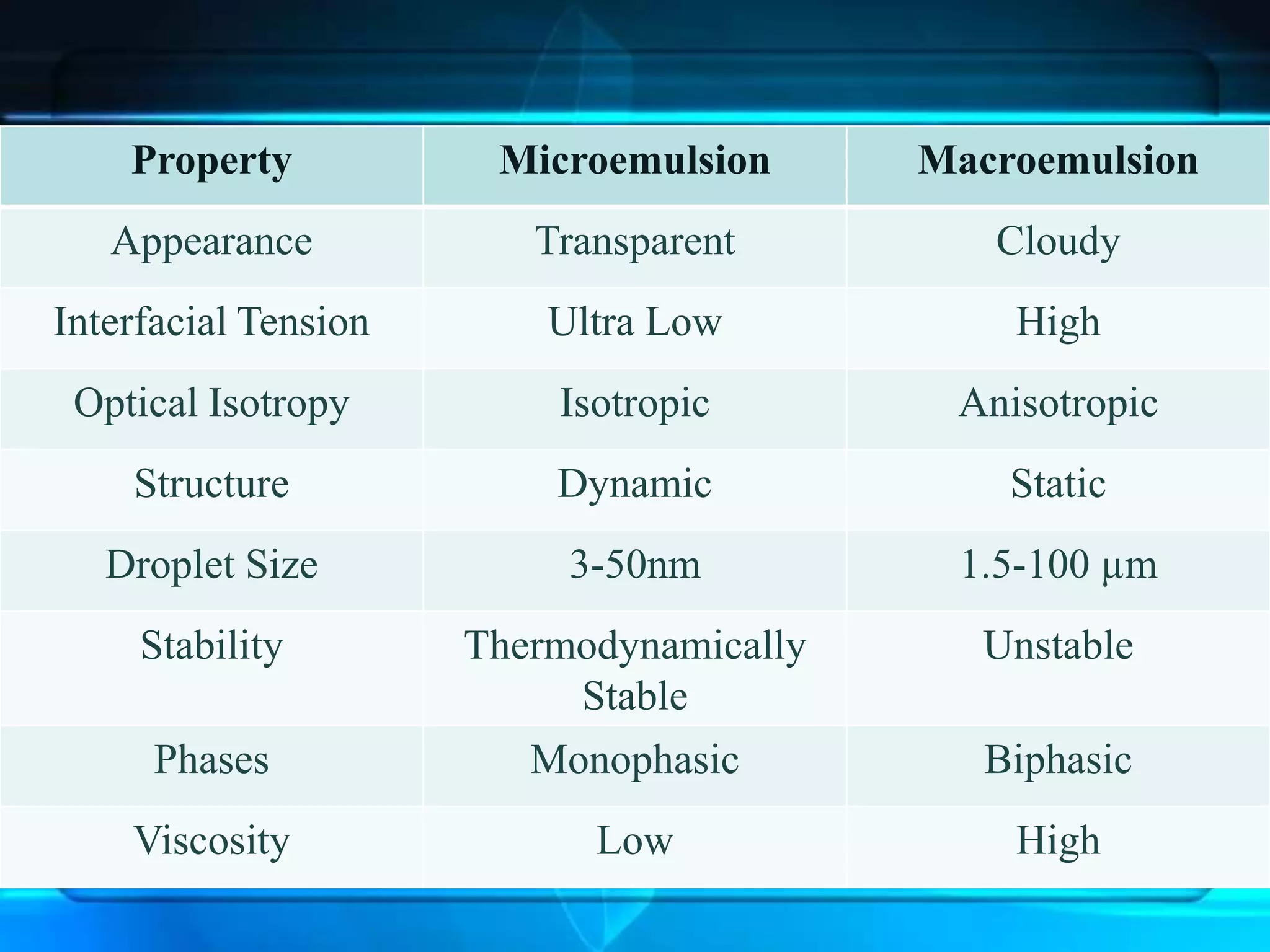

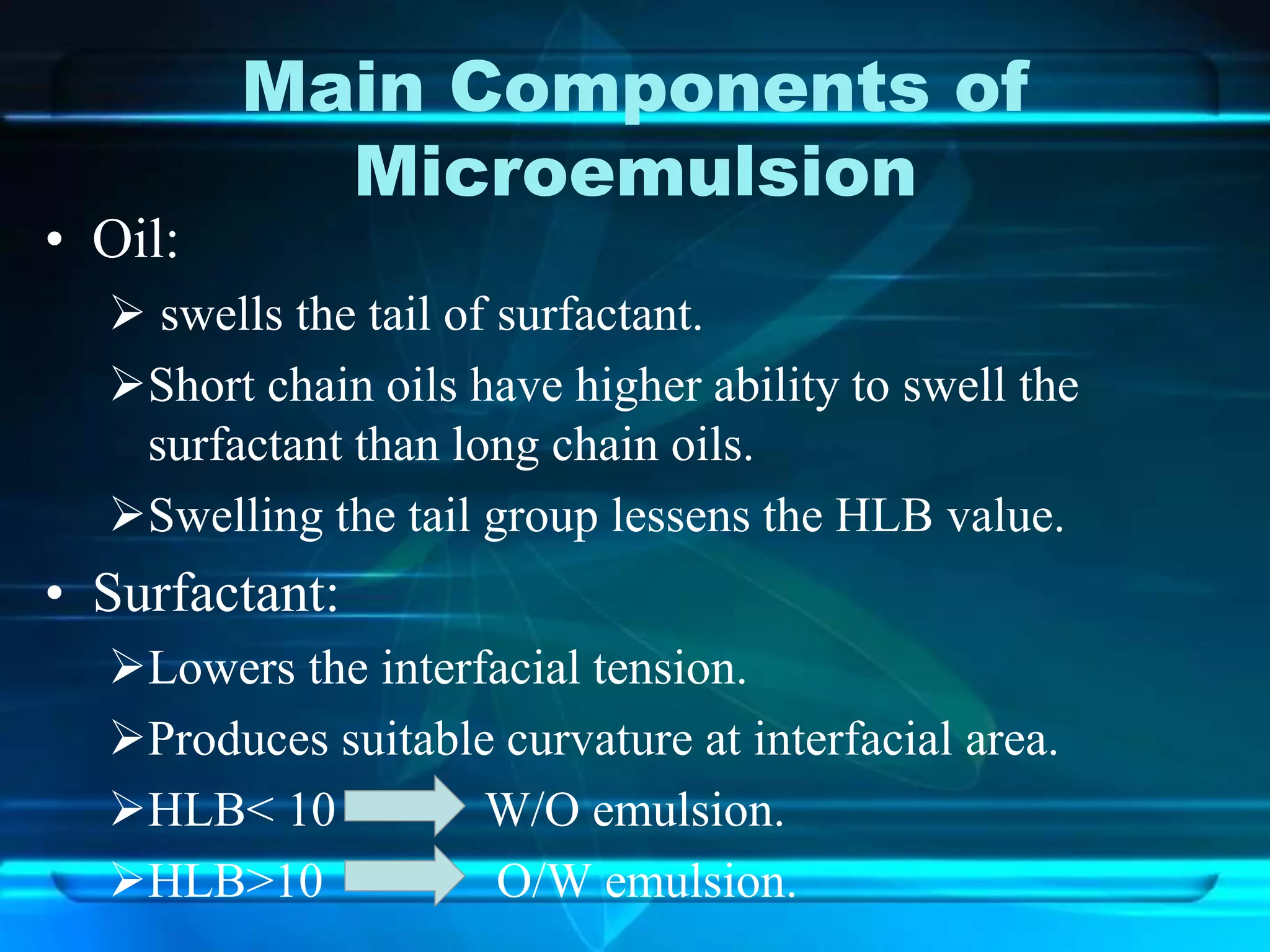

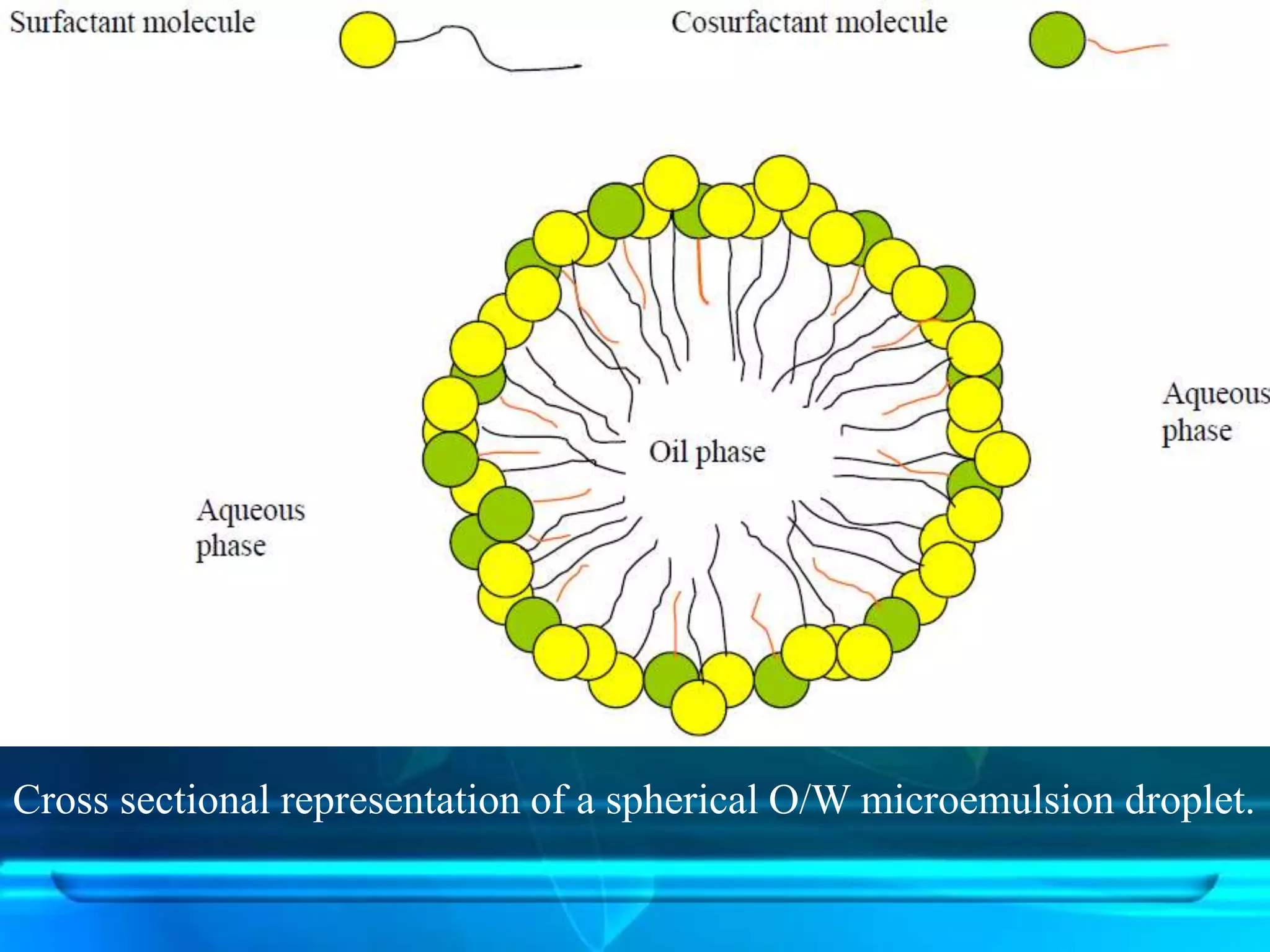

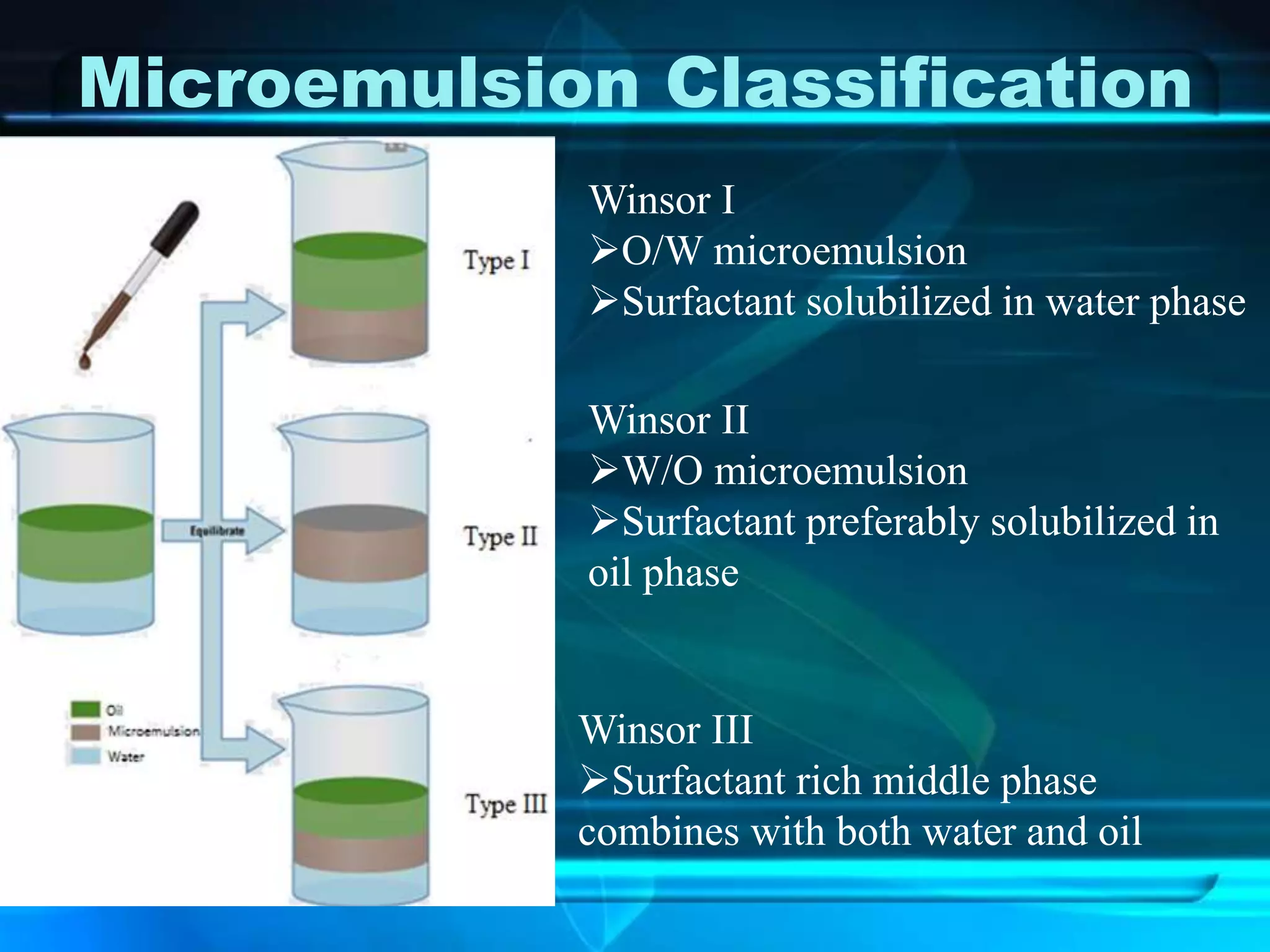

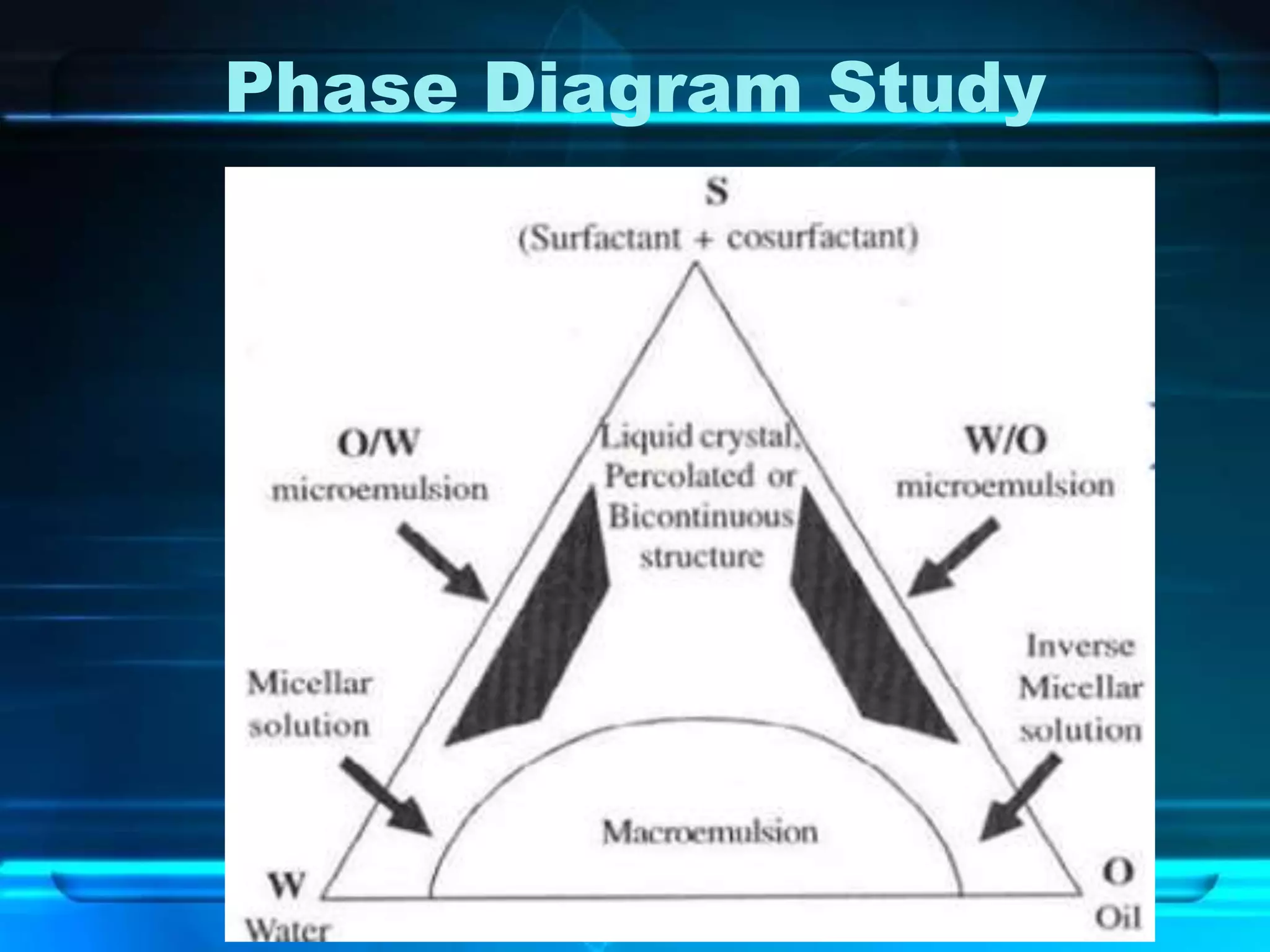

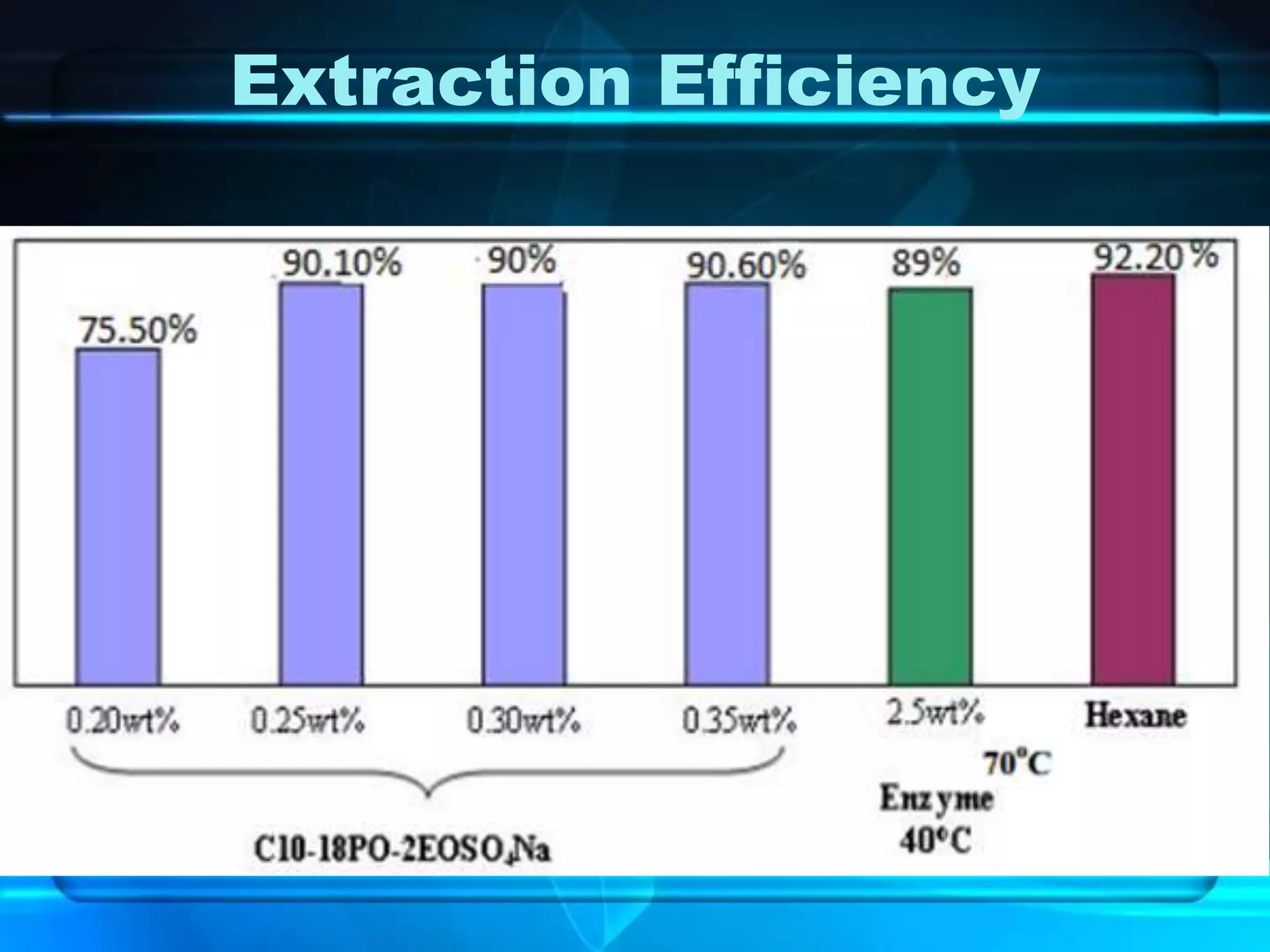

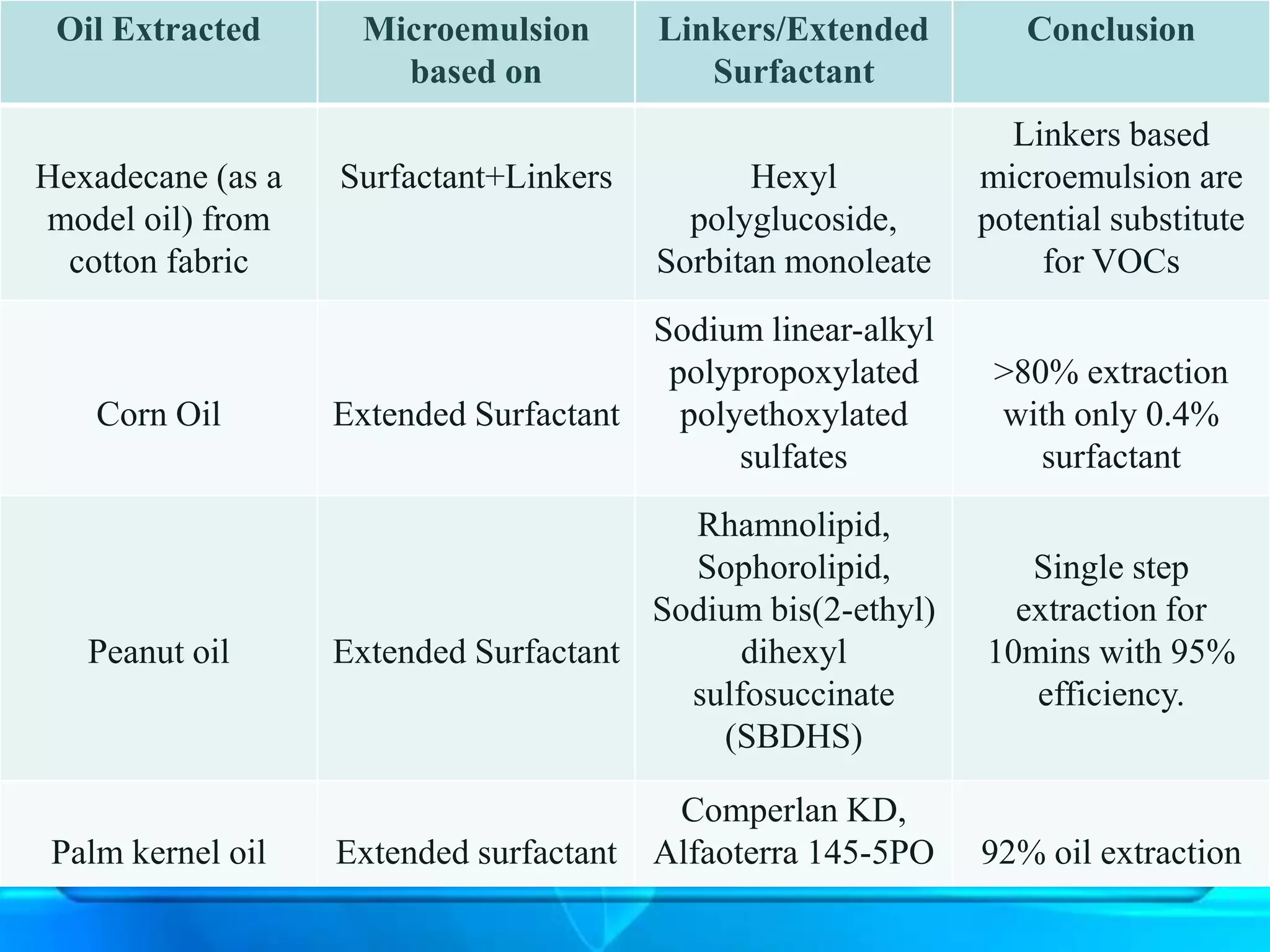

This document discusses microemulsions as an alternative technology for oil extraction that avoids the use of hazardous organic solvents. It provides background on conventional oil extraction methods and their disadvantages, such as using hexane solvents that can be harmful if not fully removed. Microemulsions are described as thermodynamically stable isotropic systems containing oil, water, and surfactants/co-surfactants that form small droplets (3-50nm). They allow efficient oil extraction at room temperature with low surfactant concentrations. Linkers can further reduce interfacial tension and facilitate microemulsion formation for improved extraction efficiency. The document concludes that microemulsion extraction is a clean approach that simultaneously recovers high quality oil and