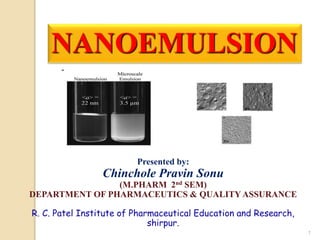

This document provides an overview of nanoemulsions. It defines nanoemulsions as oil-in-water emulsions with mean droplet diameters between 50-1000nm, usually 100-500nm. Methods of preparation include high-pressure homogenization and microfluidization. Nanoemulsions are kinetically stable and transparent/translucent. Applications include use in cosmetics, as antimicrobials, for drug delivery including cancer therapy, and as mucosal vaccines.

![ transparent or translucent O/W or W/O emulsion

droplet diameters ranging from 50-1000 nm.

[avg droplet size is between 100-500 nm]

kinetically stable unlike microemulsions which are

thermodynamically stable

Nanoparticles can exist core of particle

w/o form water

o/w form oil

Ostwald ripening is the primary instability process :

Can be reduced by the addition of a second less soluble oil phase

and/or

addition of a strongly adsorbed and water insoluble polymeric surfact](https://image.slidesharecdn.com/nanoemulsionchatap-160412060146/85/Nanoemulsion-CHINCHOLE-8-320.jpg)