The document discusses emulsions, which are mixtures of two or more liquids that do not normally mix. It defines the key types of emulsions as oil-in-water (O/W), water-in-oil (W/O), and multiple emulsions. It also explains the differences between O/W and W/O emulsions and describes detection tests that can identify the emulsion type. Finally, it provides examples of common emulsifying agents like lecithin, soap, and gum and discusses their properties and uses in emulsions.

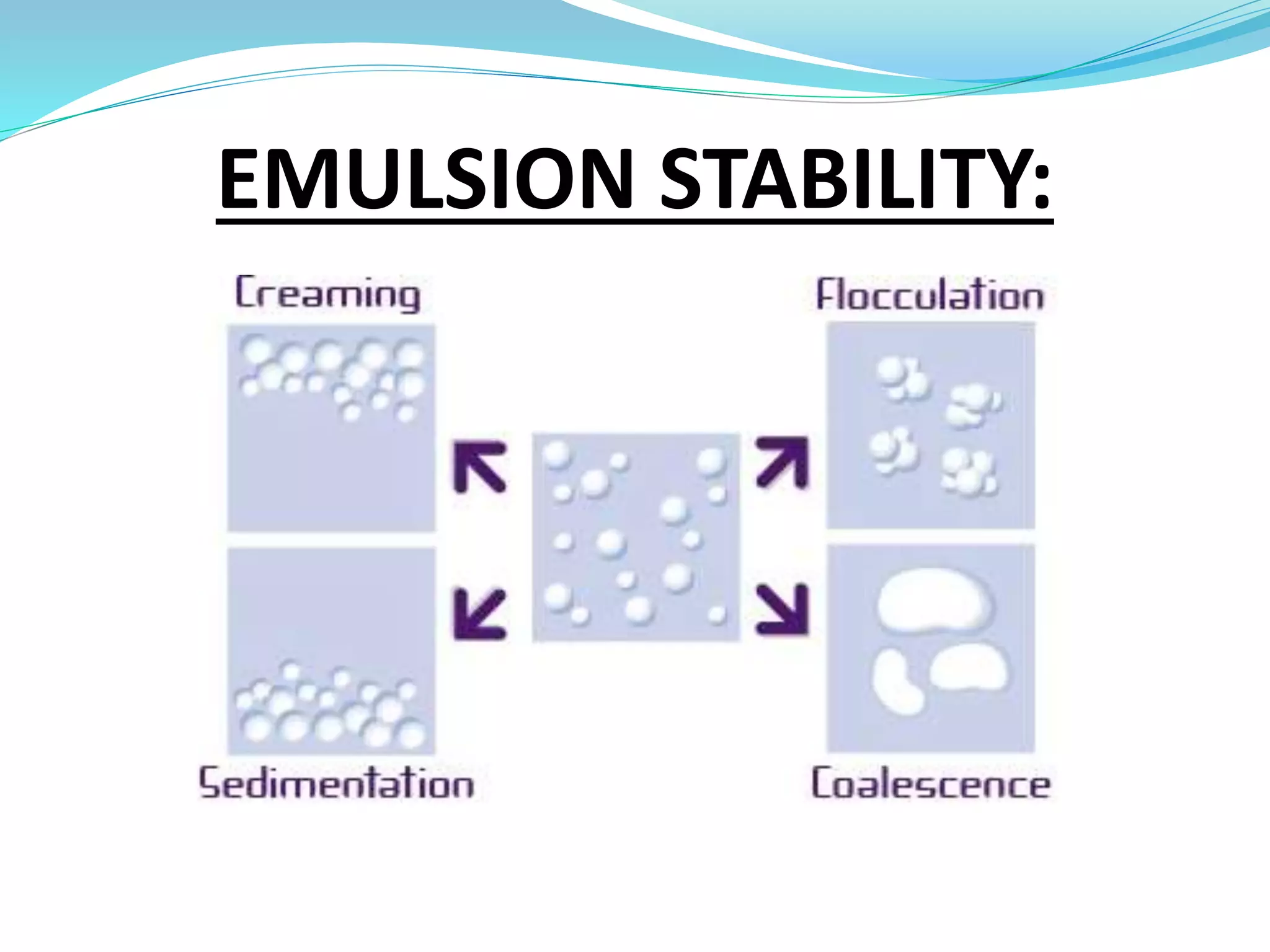

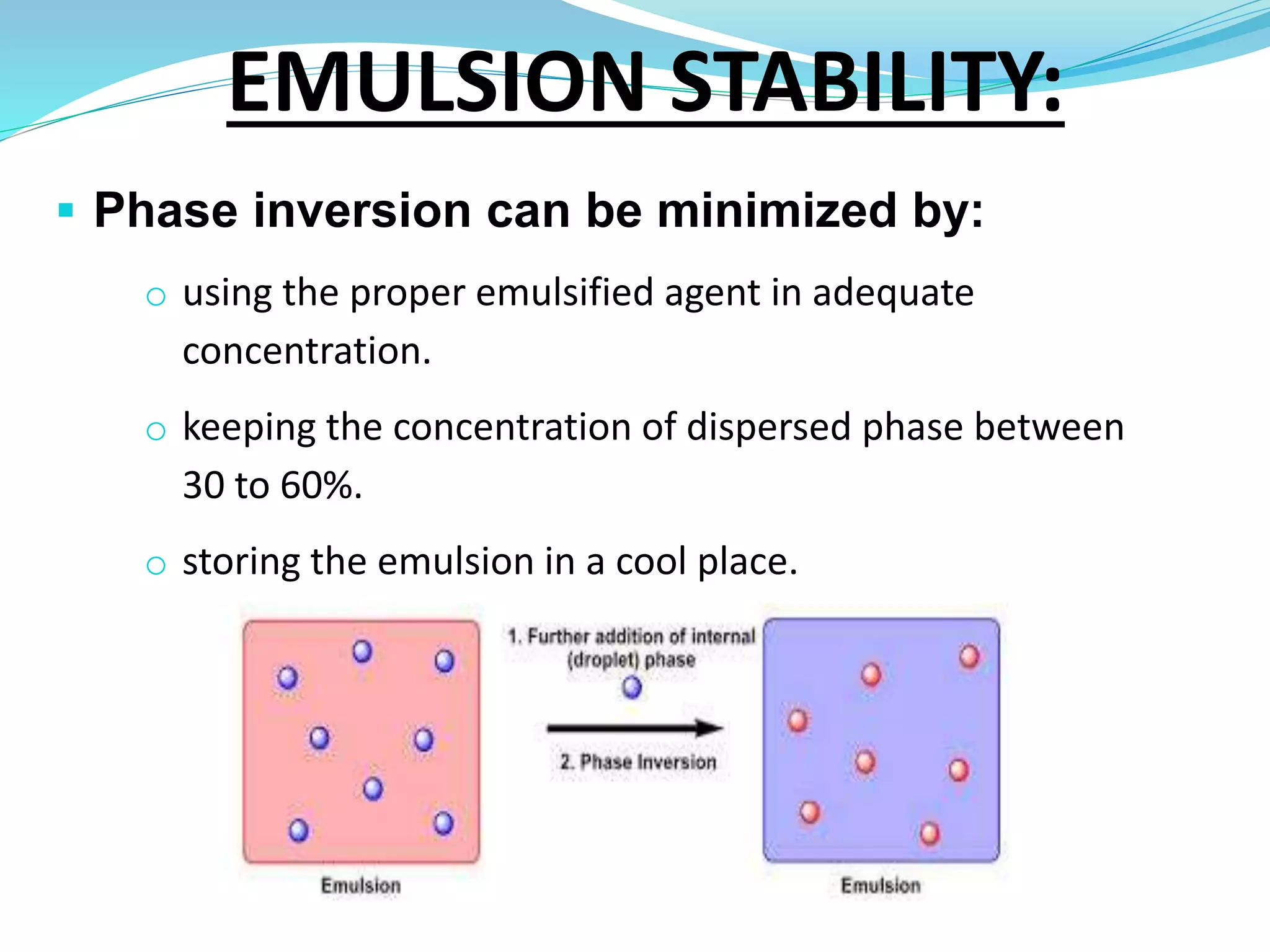

![ Factors affect creaming:

Globule size:

↑globule size ↑creaming

The density of the internal phase and External phases:

pi-pe=0 dx/dt=0

pi-pe=-ve[i.e.-ve velocity upward creaming]

pi-pe=+ve [downward creaming]

Gravity:

Constant, however centrifugation is applied

Velocity:

↑ ↓creaming

EMULSION STABILITY:](https://image.slidesharecdn.com/prestationemulsion-150510155323-lva1-app6891/75/emulsion-39-2048.jpg)

![ Nascent Method or In Situ Soup

Method:

o The two types of soaps developed by this method are calcium

soaps and soft soaps.

o Calcium soaps are W/O emulsion that contain certain

vegetable oil, such as oleic acid, in combination with Lime

water [ calcium hydroxide solution ca[0H]2 ].

o They are prepared simply mixing equal volumes of the oil and

lime water.

METHODS OF PREPARATION:](https://image.slidesharecdn.com/prestationemulsion-150510155323-lva1-app6891/75/emulsion-62-2048.jpg)