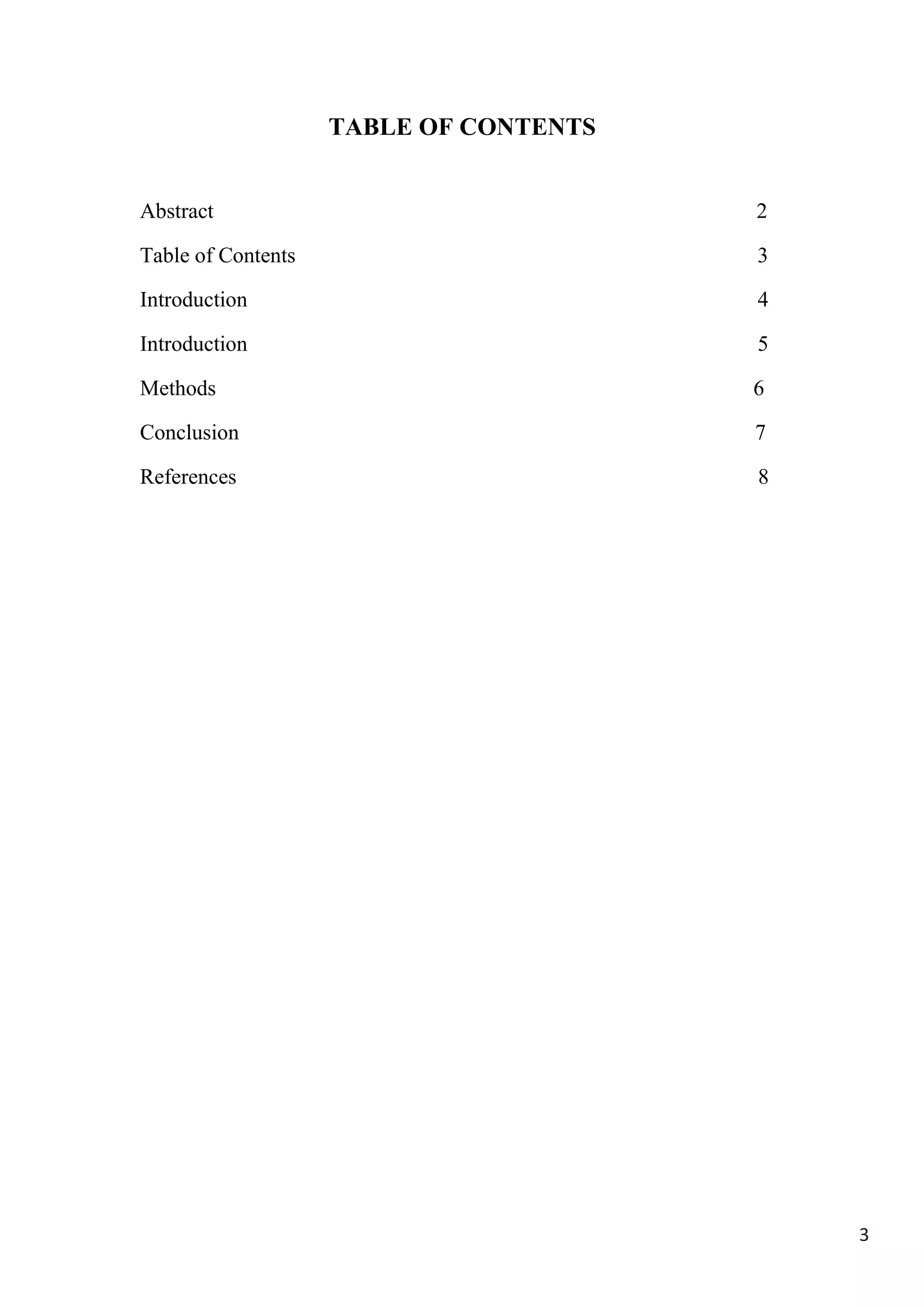

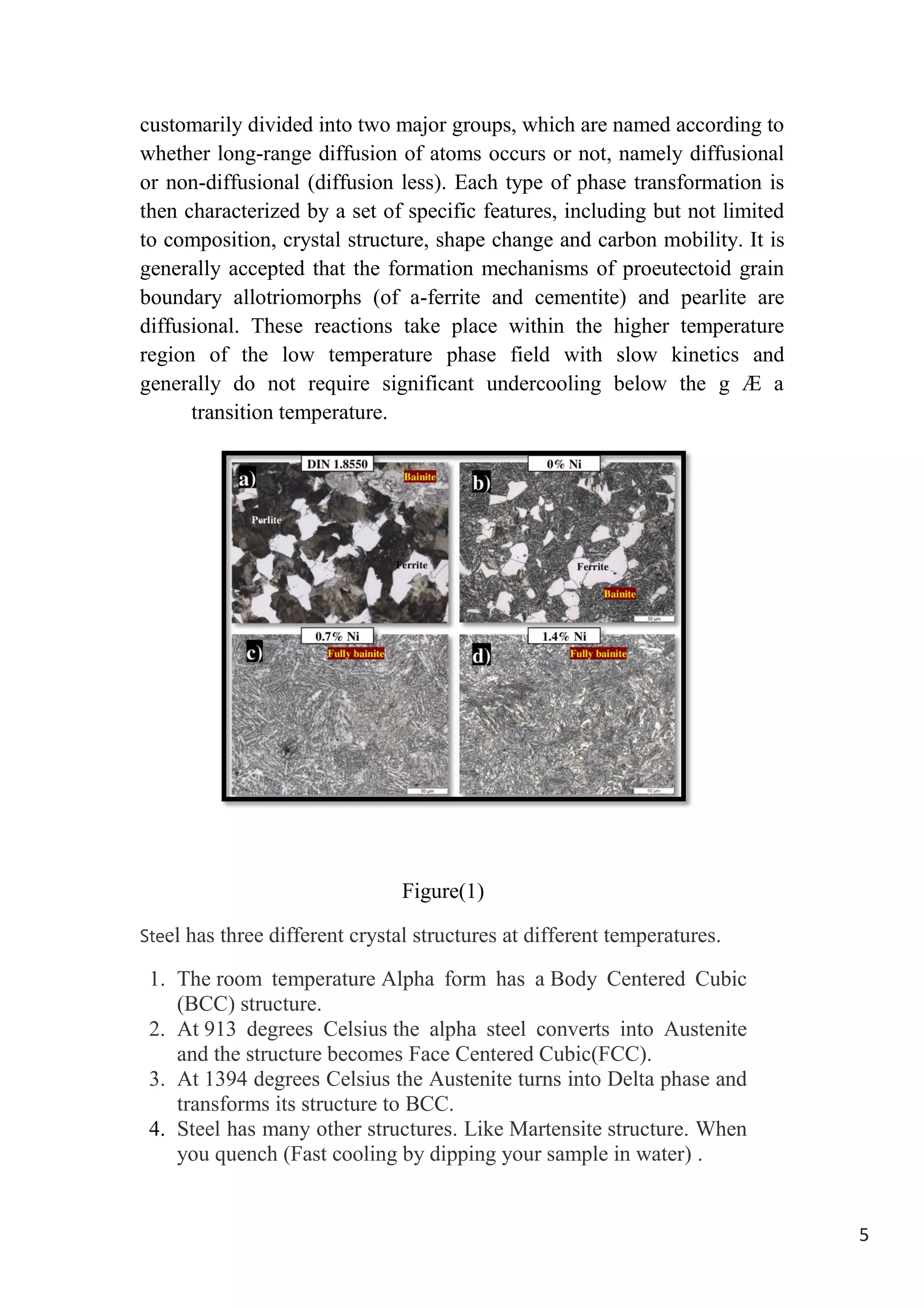

This document discusses the microstructures of steels. It begins with an abstract that defines the differences between crystal structure and microstructure. It then provides a table of contents and introduction about the importance and widespread use of steel. The next sections describe the different crystal structures of steel at various temperatures and the main phase transformations that can occur in steels based on factors like composition and heat treatment. It concludes by discussing the different types of steels defined by their carbon content or alloying elements. References are provided to related literature on steel microstructures and properties.

![8

REFERENCES

[1]. William Stephen Tait, in Handbook Of Environmentan Degradation

Of Materials(second edition),2012.

[2]. Subhasish Mohapatra, B.Tech In Metallurgy and Materials

Engineering,

[3]. Smith, William F.; Hashemi, Javad (2006). Foundations of Materials

Science and Engineering (4th ed.). McGraw-Hill.

[4]. Durand-Charre, Madeleine (2004). Microstructure of Steels and Cast

Irons. Springer.

[5]. Sufiiarov V Sh, Popovich A A, Borisov E V, Polozov I A 2015

Selective laser melting of heatresistant Ni-based alloy. Non-ferrous

Metals

[6]. Stepanova E Yu, Burnashev M A, Stepanov Yu S 2017 Additive and

hybrid technology in the manufacture of tools and tooling: state of the

economy, prospects. Izvestiya TulGU

[7]. Bazyleva O A, Bondarenko Yu A, Morozova G I and Timofeeva O B

2014 Structure, chemical composition, and phase composition of

intermetallic alloy VKNA-1V after high-temperature heat treatment and

process heating, J. Metal Science and Heat Treatment.](https://image.slidesharecdn.com/metallurgylabrawa-200629123526/75/Metallurgy-Lab-8-2048.jpg)