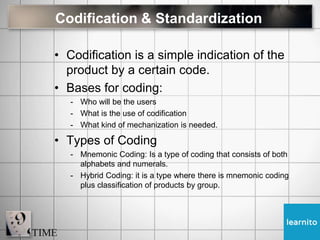

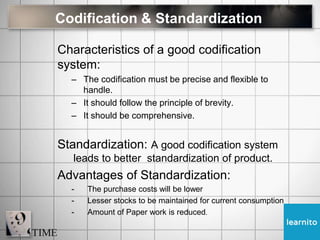

The document is a study guide on materials management for business students, covering key topics such as purchasing and procurement, factors influencing purchasing policies, material handling principles, and inventory management. It emphasizes the importance of effective materials management in reducing costs and improving efficiency in operations. Additionally, it addresses codification and standardization as essential practices for optimizing inventory processes.