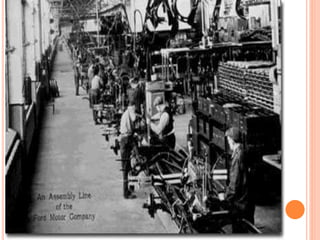

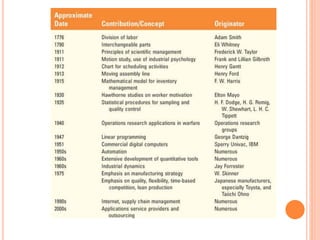

Operations management evolved from the Industrial Revolution in the 18th century, where the steam engine automated production. Scientific management in the early 20th century introduced time and motion studies to optimize workflows. Henry Ford further refined production with assembly lines and interchangeable parts. Quantitative decision models were developed in the 20th century to aid inventory management, forecasting, and project management. Japanese manufacturers influenced operations with quality and productivity improvements. Today, information technology and globalization shape operations management.