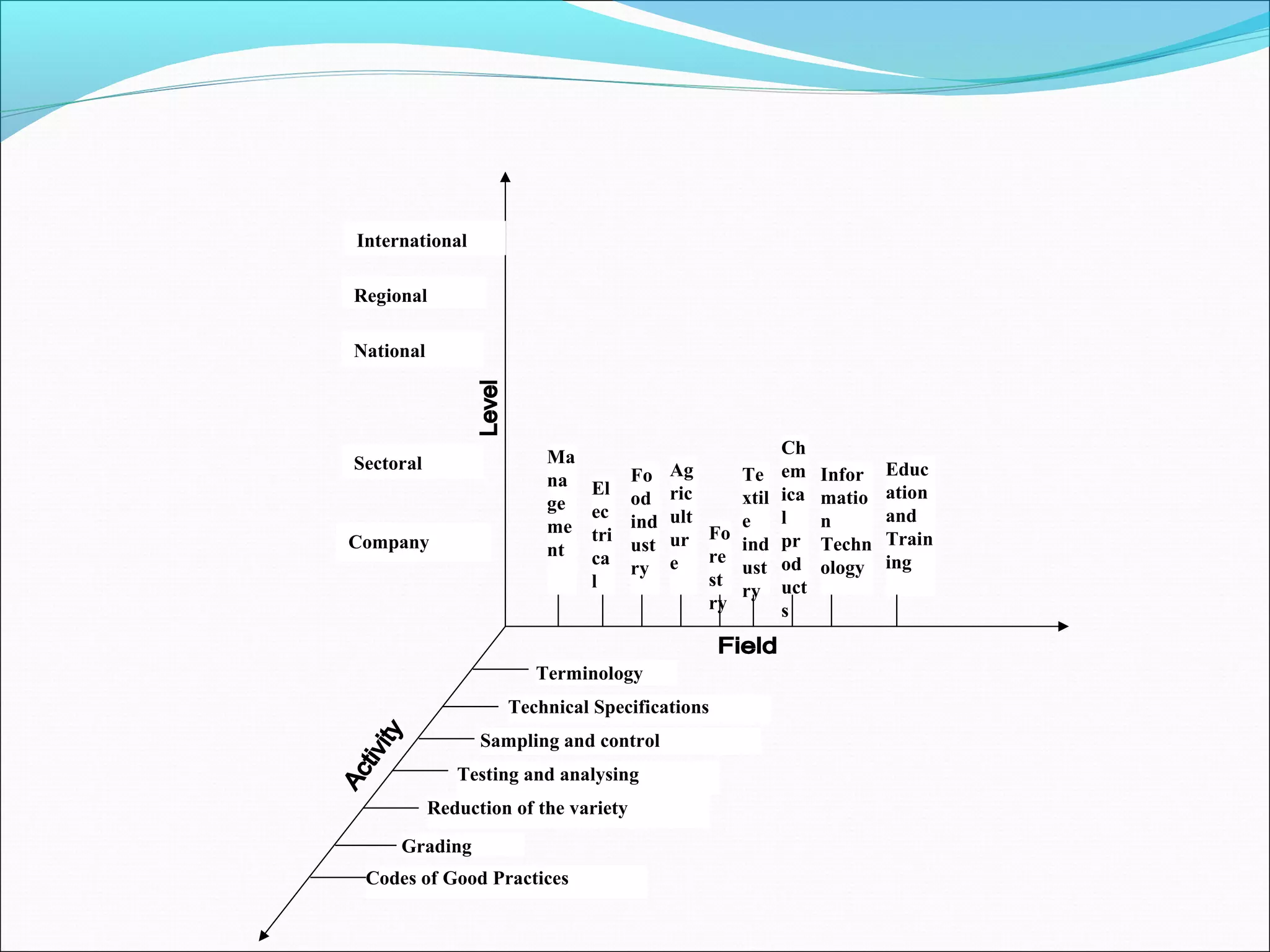

Standardization and codification aim to achieve order and efficiency. Standardization involves making products or processes consistent, while codification represents items using unique codes. This reduces costs and variability. Standardization can occur at various levels from international to company-specific. Codification benefits include accurate identification, prevention of errors, simplification, and efficient purchasing. Various coding systems exist, such as numerical, alphanumeric, and color-based approaches. The objectives of both standardization and codification are to lower costs and improve quality, inventory management, and other operational efficiencies.