Definition of Productivity: Measuring Efficiency and Resource Use

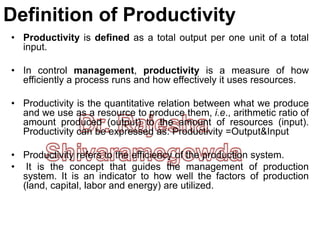

- 1. Definition of Productivity • Productivity is defined as a total output per one unit of a total input. • In control management, productivity is a measure of how efficiently a process runs and how effectively it uses resources. • Productivity is the quantitative relation between what we produce and we use as a resource to produce them, i.e., arithmetic ratio of amount produced (output) to the amount of resources (input). Productivity can be expressed as: Productivity =Output&Input • Productivity refers to the efficiency of the production system. • It is the concept that guides the management of production system. It is an indicator to how well the factors of production (land, capital, labor and energy) are utilized.

- 6. Introduction Material management is an approach for planning, organizing, and controlling all those activities principally concerned with the flow of materials into an organization. The scope of Materials Management varies greatly from company to company and may include material planning and control, production planning, Purchasing, inventory control, in-plant materials movement, and waste management.

- 7. What is Materials Management? • Coordinating function that balances the conflicting objectives of marketing, production, and finance by managing the flow of Materials. • Balancing the Resources of the company with Customer Demand.

- 8. Role of Materials Management • Make the best use of company resources • Provide the desired level of customer service (demand)

- 9. •To gain economy in purchasing •To satisfy the demand during period of replenishment •To carry reserve stock to avoid stock out •To stabilize fluctuations in consumption •To provide reasonable level of client services Purpose of Material Management

- 10. Objective of material management Primary • Right price • High turnover • Low procurement • & storage cost • Continuity of supply • Consistency in quality • Good supplier relations • Development of personnel • Good information system Secondary •Forecasting •Inter-departmental harmony •Product improvement •Standardization •Make or buy decision •New materials & products •Favorable reciprocal relationships

- 11. Materials management functions Material planning and programming Purchasing and outsourcing Inventory control Storekeeping and warehousing Codification

- 14. Definition of Bidding • General: Indication of willingness to buy or sell goods or services or to undertake a task, at a specific price and within a specific timeframe. • Contracting: Complete proposal (submitted in competition with other bidders) to execute specified job(s) within prescribed time, and not exceeding a proposed amount (that usually includes labor, equipment, and materials). The bid-receiving party may reject the bid, make a counter offer, or turn it into a binding contract by accepting it. See also offer and proposal. • Financial markets: Highest price at which prospective buyers are willing to buy commodities, foreign exchange, or securities.

- 15. • Bidding aims at obtaining goods and services at the lowest prices by stimulating competition, and by preventing favoritism. (1)Open competitive bidding (also called open bidding), the sealed bids are opened in full view of all who may wish to witness the bid opening; (2)Closed competitive bidding (also called closed bidding), the sealed bids are opened in presence only of authorized personnel.

- 18. Vendor Rating • Vendor Rating (also called: supplier rating) is a system used by buying organizations or industry analysts to record, analyze, rank and report the performance of a supplier in terms of a range of predefined criteria, which may include such things as: Quality of the product or service.

- 20. Ethics in Purchasing • Ethics play a major role in procurement and are considered more important as technology and consumer behavior change. • Being ethical means being in accordance with the rules or standards for right conduct or practice, especially the standards of a profession.

- 21. Ethical Practices • An ethics policy • Confidentiality of information • Fair and unbiased treatment • Ethics Training • Audits • Integrity: Integrity is the quality of being honest and having strong moral principles

- 22. Lead Time The lead time is the delay applicable for inventory control purposes. This delay is typically the sum of the supply delay, that is, the time it takes a supplier to deliver the goods once an order is placed, and the reordering delay, which is the time until an ordering opportunity arises again. • Lead time is the time that elapses between the placing of an order (either a purchase order or a production order issued to the shop or the factory floor) and actually receiving the goods ordered. • If a supplier (an external firm or an internal department or plant) cannot supply the required goods on demand, then the client firm must keep an inventory of the needed goods. The longer the lead time, the larger the quantity of goods the firm must carry in inventory.

- 23. Purchase requisitions Purchase requisitions are a document used when an employee needs to make a purchase or an order request on behalf of their company. It is a document that is used to inform department managers or the purchasing officer of the decision so that the purchasing department can start the purchasing process. The finance team will also use this document to coordinate reporting procedures with the accounting department as well.

- 24. Importance of Purchase Requisition • It Initiates the Purchasing Process • It is a Control Tool • Protecting the Business • Centralization of the Procurement Process

- 25. Purchase Order • A purchase order is a source document used by the purchasing department to place an order with a vendor or supplier. • In other words, this is the contract that a buyer drafts to purchase goods from a seller.

- 26. Amendment • A minor change or addition designed to improve a text, piece of legislation, etc

- 27. Purchase Order Amendment • After a PO has been approved, it is necessary to record all changes that are made to the purchase order. • This is accomplished through the Purchase Order Amendment process. • Time, quality, quantity, place, etc

- 28. Purchase Order Forms • A purchase order form is a template used for a purchase order. • The purchase order is a written (or electronic) document meant to record business transactions between a buyer and a seller. • The buyer issues the purchase order, and once the seller accepts the order, a legally binding contract forms between the two parties. Buyer Seller Purchase Order Number: Order Information/Item Description Shipping Address Shipping Date Billing Address Signatures Order Date Currency Payment Method Delivery Method Shipping Costs Which Party is Paying Shipping Costs Shipping Information/Tracking Number Terms and Conditions Governing Law

- 31. © 2011 Pearson Education, Inc. publishing as Prentice Hall Inventory Management The objective of inventory management is to strike a balance between inventory investment and customer service

- 32. Inventory Process stage Demand Type Number & Value Other Raw Material WIP Finished Goods Independent Dependent A Items B Items C Items Maintenance Repair Operating Inventory Classifications

- 33. © 2011 Pearson Education, Inc. publishing as Prentice Hall Functions of Inventory 1. To decouple various parts of the production process by covering delays 2. To protect the company against fluctuations in demand 3. To provide a selection for customers 4. To take advantage of quantity discounts 5. To hedge against inflation

- 34. Problems Caused by Inventory • Inventory ties up working capital • Inventory takes up space • Inventory is prone to: – Damage, Pilferage (stealing) and Obsolescence (expiry) • Inventory hides problems

- 35. The Material Flow Cycle Figure 12.1 Input Wait for Wait to Move Wait in queue Setup Run Output inspection be moved time for operator time time Cycle time 95% 5%

- 37. ABC inventory analysis • ABC inventory analysis is a method used to classify a business’s stock items into three categories – A, B and C, based on their value to the business. • A items are the most important in terms of the value they bring a company, whilst C items are the least valuable. • The objective of ABC inventory analysis is to help managers focus their time on their most valuable / important products and adapt their inventory control policies accordingly.

- 38. The 80/20 rule of ABC analysis • You’re no doubt familiar with the ’80/20 rule’, also known as the Pareto Principle. • This rule of thumb can also be applied to inventory consumption, where 80% of a business’s annual sales value comes from 20% of its items e.g category A items. Categories B and C then make up the remaining 20%. • How the 20% is split between category B and C items will vary, based on a business’s product portfolio. • The graph below shows how ABC analysis conforms with the Pareto Principle. • You can see that 20% of the annual sales volume comes from a small number of A category items, while a large number of B, C and D items make up the remaining 20%.

- 41. VED Analysis • This is an analysis whose classification is dependent on the user’s experience and perception. • This analysis classifies inventory according to the relative importance of certain items to other items, like in spare parts. In VED Analysis, the items are classified into three categories which are: • Vital – inventory that consistently needs to be kept in stock. • Essential – keeping a minimum stock of this inventory is enough. • Desirable – operations can run with or without this, optional.

- 42. FSN analysis • This acronym stands for Fast-moving, Slow- moving and Non-moving inventory items. • The purpose of FSN analysis is to consider quantity, the rate of consumption of products and how often they are issued or used and to use this information to guide decisions about placement in the warehouse (considering picking and packing to reduce time and labor), frequency of reordering or even phasing out of certain items.

- 44. Definition: Inventory Costs • Inventory costs are the costs associated with the procurement, storage and management of inventory. • It includes costs like ordering costs, carrying costs and shortage / stock out costs.

- 46. • Ordering cost of inventory refers to the cost incurred for procuring inventory. It includes cost of purchase and the cost of inbound logistics. In order to minimize the ordering cost of inventory we make use of the concept of EOQ or Economic Order Quantity. • Carrying cost of inventory refers to the cost incurred towards inventory storage and maintenance. The inventory storage costs typically include the cost of building rental and other infrastructure maintained to preserve inventory. • Shortage or stock out costs and cost of replenishment are the costs incurred in unusual circumstances. They usually form a very small part of the total inventory cost.

- 47. EOQ MODEL • Economic order quantity (EOQ) is the ideal order quantity a company should purchase to minimize inventory costs such as holding costs, shortage costs, and order costs. • This production-scheduling model was developed in 1913 by Ford W. Harris and has been refined over time. • The formula assumes that demand, ordering, and holding costs all remain constant.

- 48. EOQ FORMULA • Retail clothing shop carries a line of men’s jeans, and the shop sells 1,000 pairs of jeans each year. It costs the company $5 per year to hold a pair of jeans in inventory, and the fixed cost to place an order is $2. • square root of (2 x 1,000 pairs x $2 order cost) / ($5 holding cost) or 28.3 with rounding. • The ideal order size to minimize costs and meet customer demand is slightly more than 28 pairs of jeans. • A more complex portion of the EOQ formula provides the reorder point.

- 49. Limitations of Using EOQ • The EOQ formula assumes that consumer demand is constant. • The calculation also assumes that both ordering and holding costs remain constant. • This fact makes it difficult or impossible for the formula to account for business events such as changing consumer demand, seasonal changes in inventory costs, lost sales revenue due to inventory shortages, or purchase discounts a company might realize for buying inventory in larger quantities.

- 50. Definition of Safety Stock • Safety stock is an additional quantity of an item held by a company in inventory in order to reduce the risk that the item will be out of stock. • Safety stock acts as a buffer in case the sales of an item are greater than planned and/or the company's supplier is unable to deliver additional units at the expected time. • If the company is a manufacturer, a safety stock of materials could minimize the risk of production being disrupted.

- 51. Benefits of safety stocks • Demand uncertainty • Lead Time uncertainty

- 53. Re-Order Point • The reorder point (ROP) is the level of inventory which triggers an action to replenish that particular inventory stock. • It is a minimum amount of an item which a firm holds in stock, such that, when stock falls to this amount, the item must be reordered.

- 55. Quantity Discount • A quantity discount is an incentive offered to a buyer that results in a decreased cost per unit of goods or materials when purchased in greater numbers. • A quantity discount is often offered by sellers to entice customers to purchase in larger quantities.

- 56. (1) Noncumulative quantity discount; (2) Cumulative quantity discount (3) Free merchandise. Noncumulative quantity discount is based on a single purchase whereas cumulative quantity discount is based on purchases made over time. Other types of discounts are cash discounts, trade discounts, and promotional discounts.

- 57. Total Productive Maintenance (TPM) • Total productive maintenance (TPM) is a method of maintaining and improving the integrity of production and quality systems through the machines, equipment, employees and the supporting processes. • TPM can be of great value and its target is to improve core business processes. • The phrase TPM was first used in 1961 by the Japanese company Denso. • TPM is especially meant for companies with a lot of machines that involve high maintenance costs.

- 58. Features of TPM • Productivity improvement • Preventive maintenance concept • Everyone is responsible • Multidisciplinary teams • Continuous improvement • Perfection

- 60. Definition Breakdown maintenance is maintenance performed on equipment that has broken down and is unusable. It is based on a breakdown maintenance trigger. It may be either planned or unplanned.