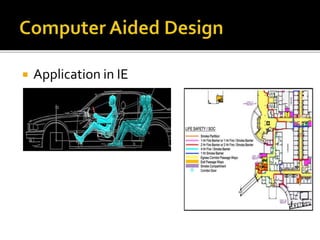

Industrial engineering is a branch of engineering that deals with optimization of complex systems involving people, equipment, materials and processes. It uses principles from engineering, management science and social sciences. Some key areas of industrial engineering include operations research, operations management, project management, job design, supply chain management, quality engineering, engineering design process and facility management. Other related fields include just-in-time production, computer-aided design, computer-aided manufacturing and their applications in industrial engineering.