Embed presentation

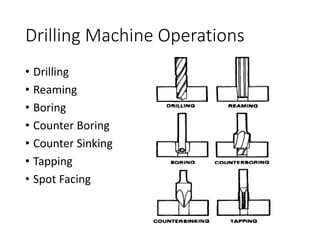

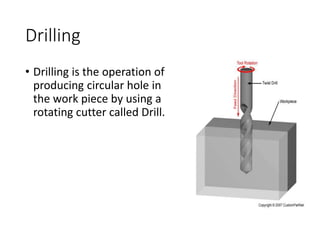

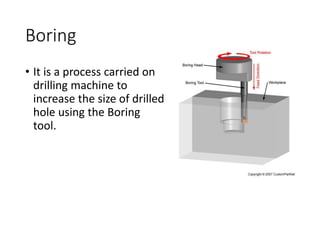

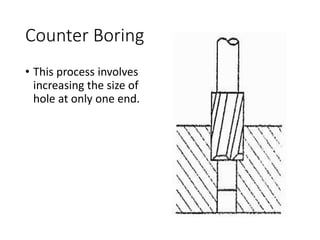

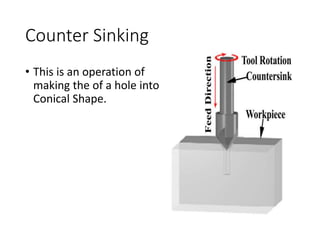

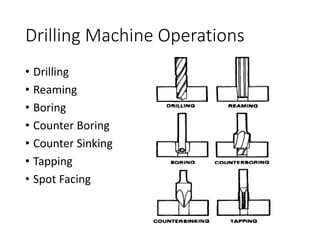

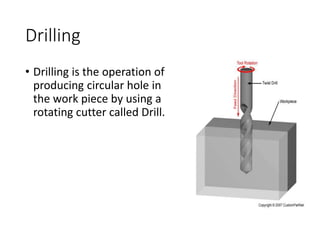

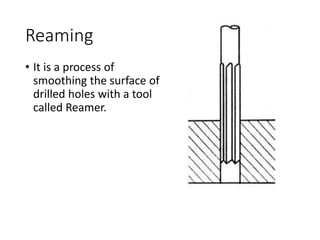

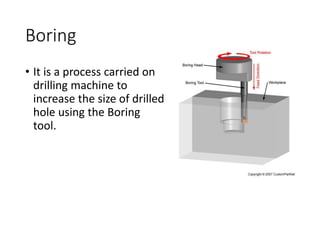

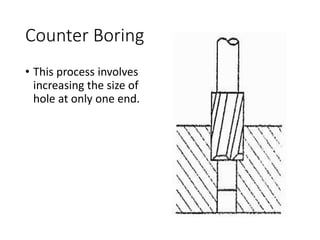

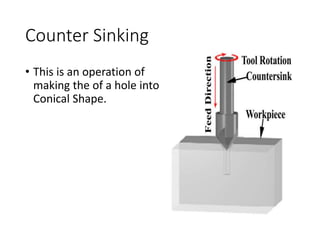

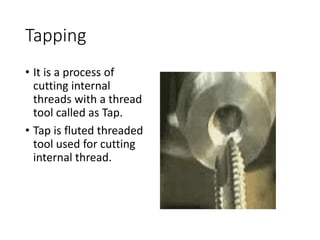

The document discusses various operations that can be performed on a drilling machine, including drilling, reaming, boring, counter boring, counter sinking, tapping, and spot facing. It provides brief definitions and descriptions of each operation, such as drilling produces circular holes using a rotating drill bit, reaming smooths drilled holes using a reamer tool, and tapping cuts internal threads using a threaded tap tool. The document was created by an engineering student for a class project on drilling machine operations.