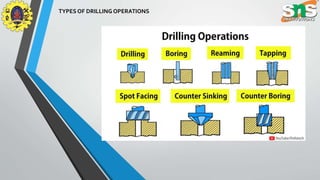

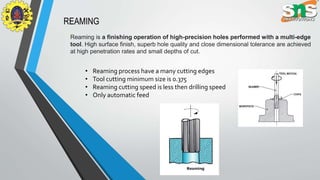

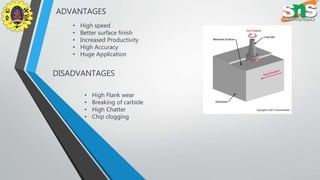

This document discusses various multi-point cutting and abrasive machining processes used at SNS College of Technology. It describes drilling operations like reaming, boring, and tapping. Reaming finishes holes with multi-edge tools for high precision. Boring increases hole size using a boring tool on a drilling machine. Tapping cuts internal threads. Milling operations like face milling and end milling are also outlined that use rotary cutters to remove material in various axes. Advantages of these processes include high speed, accuracy and productivity while disadvantages include high wear and chatter.