The document discusses supply chain and logistics concepts including:

1) Physical distribution involves choosing warehouses and transportation carriers to deliver goods in the desired time at lowest cost. Physical distribution has expanded into supply chain management.

2) Supply chain management involves procuring inputs, efficiently converting them into finished products, and dispatching them to customers.

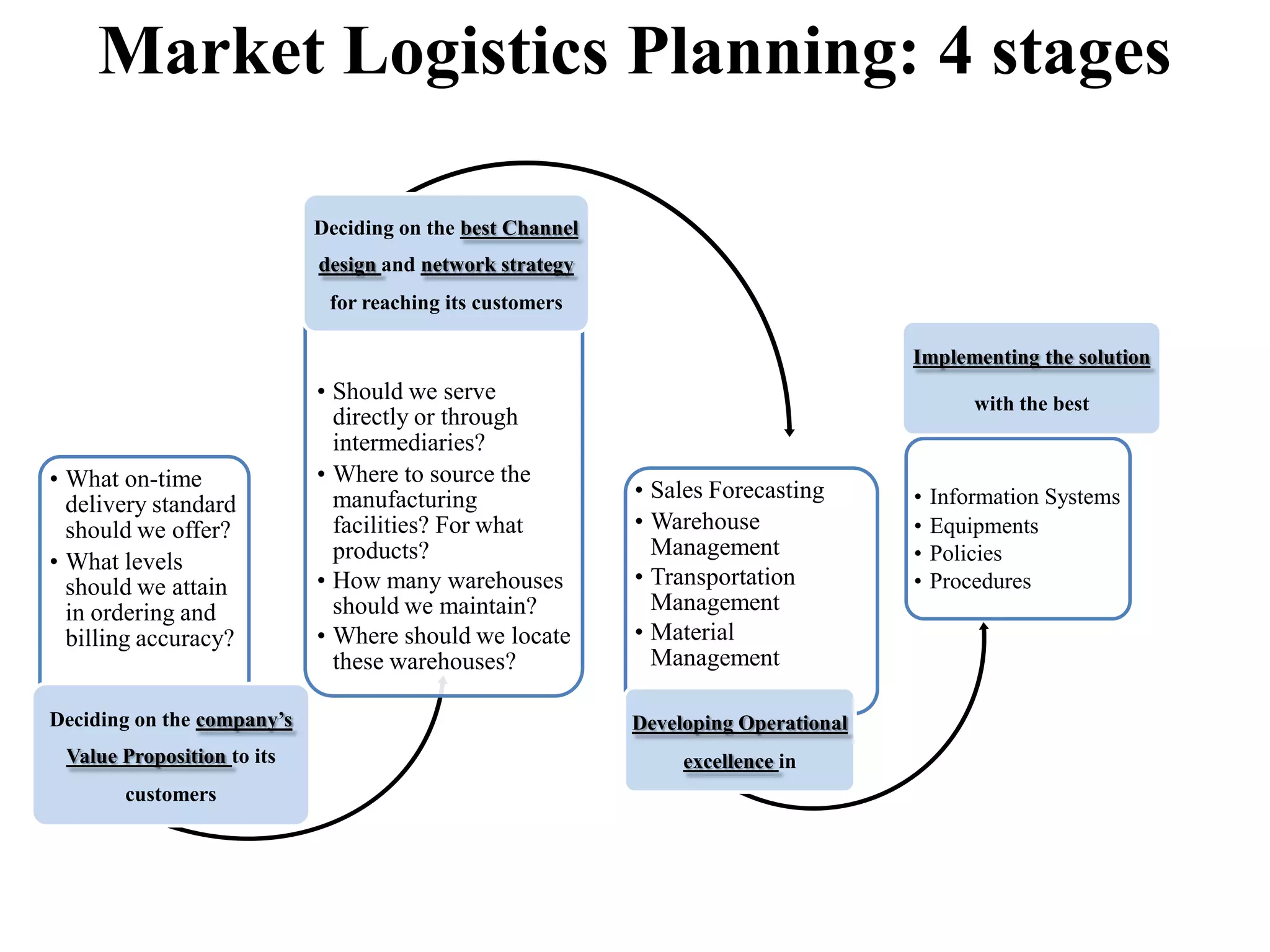

3) Market logistics planning involves four stages - deciding on a value proposition, developing operational excellence, implementing solutions, and deciding on a channel/network strategy.